Festo DHTG User Manual

Page 33

DHTG

Festo – DHTG – 1404d English

33

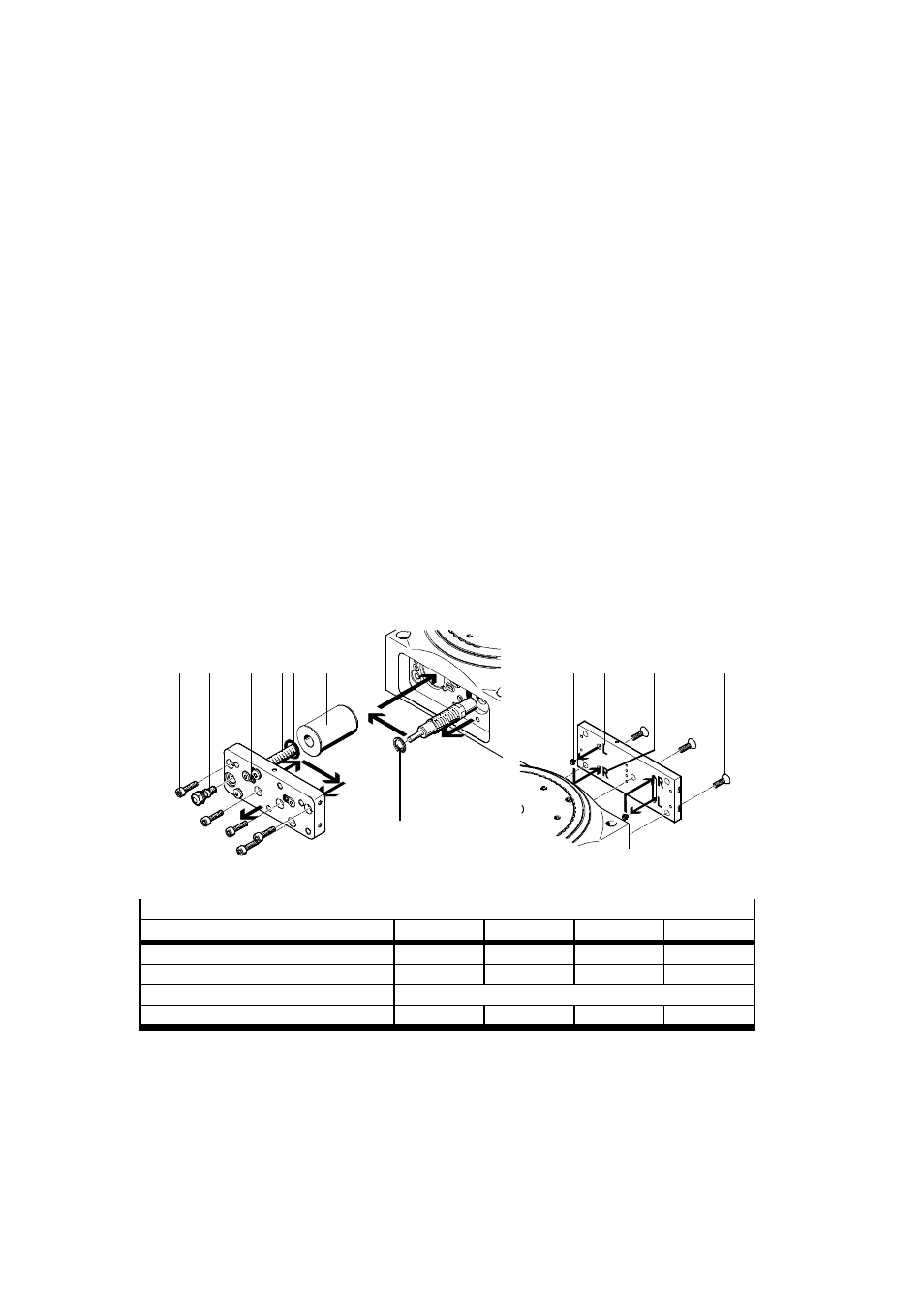

Conversion from clockwise rotation (as supplied) to anti-clockwise rotation:

1. Loosen the clamping element (K) of the adjusting screw one rotation.

2. Unscrew the adjusting screw

6 a few rotations.

3. Unscrew flow control screw

aJ and the fastening screws (M) from the sub-base.

4. Using pliers, remove the retaining ring (S) on the shock absorber.

5. Fit the following:

–

the shock absorber with the retaining ring in the adjacent hole

–

the O-ring (P) / buffer (for DHTG-65) in the adjacent groove

–

the distance piece (T) in the same hole (distance piece omitted for 2/3 index stations)

–

the sub-base with the fastening screws and the flow control screw in reverse sequence

(tightening torque

Tab. 17).

6. Unscrew the fastening screws (N) on the stop plate.

7. Unscrew:

–

both locking screws (O) on the rear of the stop plate to begin with,

–

then screw them in again into the open holes (tightening torque

Tab. 17).

The open holes

(R) or (L) in Fig. 14 determine the direction of rotation

(Holes (R) open: clockwise rotation).

8. Screw the fastening screws (N) on the stop plate again (tightening torque

Tab. 17).

The rotary indexing table remains pneumatically controlled as before.

9. Screw in the adjusting screw

6 until the desired cushioning is achieved

Fig. 11.

10.Tighten the clamping element (K) of the adjusting screw (tightening torque

Tab. 15).

(M) aJ

(N)

(O)

(P)

(K)

(L)

(R)

(T)

(S)

6

Fig. 14

Tightening torque

Size

65

90

140

220

Flow control screw

aJ

[Nm]

1.5

1.5

5.5

5.5

Fastening screws (M)

[Nm]

2.9

2.9

9.9

9.9

Plug screw (O)

[Nm]

0.5

Fastening screws (N)

[Nm]

1.5

2.9

5.9

5.9

Tab. 17