6 commissioning, 6commissioning – Festo DHTG User Manual

Page 28

DHTG

28

Festo – DHTG – 1404d English

6

Commissioning

Warning

Risk of injury from rotating masses.

•

Make sure nobody can place his/her hand in

the positioning range of the DHTG and that

no objects lie in its path (e. g. by providing a

protective screen).

Note

Incorrect functioning due to inaccurate toothed rod position. When the DHTG is

exhausted, the resetting force of the shock absorber can push the rotary table out of

the end position and into an undefined position.

•

Before each commissioning procedure, pressurise the last pressurised connection:

–

Connection (B) for clockwise/anti-clockwise rotation

–

Connection (C) or (D) for reciprocating operation/flexible control.

Note

Clockwise rotation is controlled internally through the flow control valve

aJ.

Anti-clockwise rotation / reciprocating operation must be controlled externally through

an additional one-way flow control valve GRLA (

www.festo.com/catalogue).

•

Screw the flow control screw

aJ:

–

in completely,

–

then loosen one rotation

•

Slowly pressurise the complete system with at least 4 bar.

•

Start a test run Tab. 10.

•

Check in a test run at low pulse frequency whether the following

modifications are necessary:

–

Readjustment of the proximity switches

–

Increase the speed step-by-step by unscrewing the

flow-control screw

aJ

–

Set the cushioning.

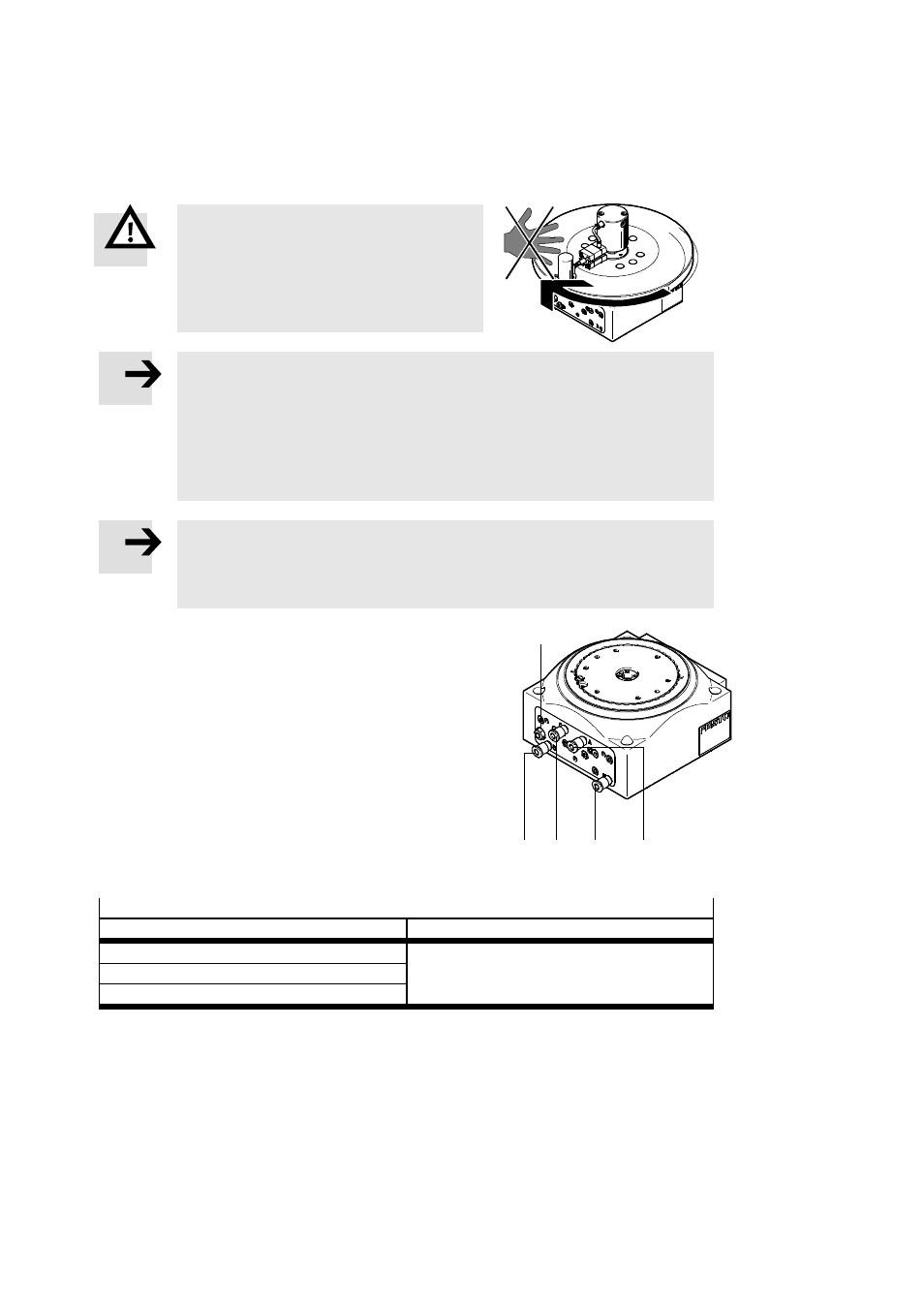

(D)

(A)

(B)

(C)

aJ

Fig. 10

Direction of rotation of plate

Clockwise/anti-clockwise rotation

Reciprocating operation/flexible control

1)

Basic position: Connection (B) pressurised

see examples Tab. 11 to Tab. 13

1. Slowly pressurise connection (A)

2. Provide clock pulses for the valve

1)

Internal flow control in one direction only (if necessary throttle different direction externally)

Tab. 10

Fig. 9