2 function and application, 3 transport and storage, 4 requirements for product use – Festo DHTG User Manual

Page 23: 2function and application, 3transport and storage, 4requirements for product use

DHTG

Festo – DHTG – 1404d English

23

2

Function and application

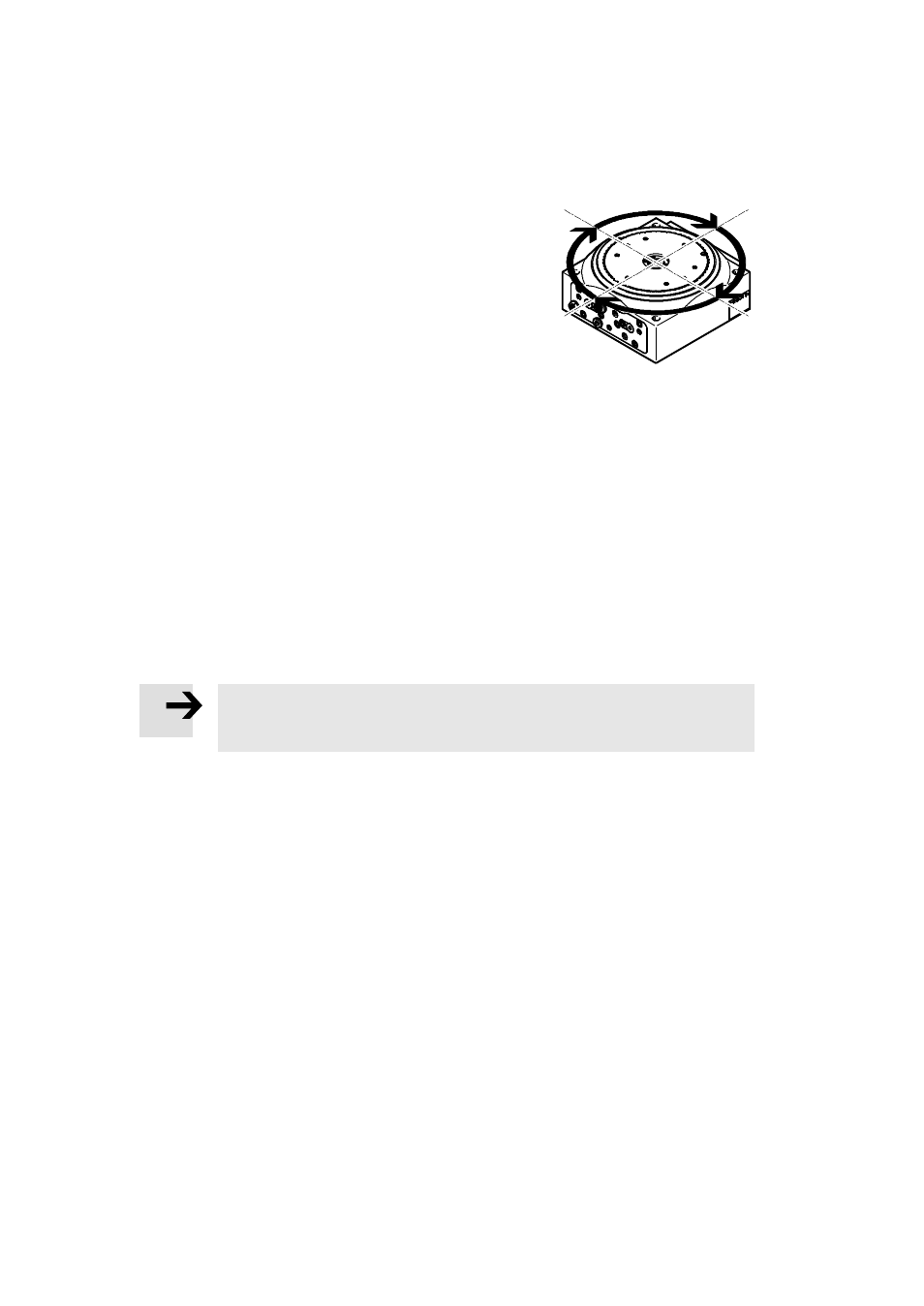

The DHTG rotary indexing table is a double-acting rotary drive

based on the toothed rack and pinion principle with forced locking

(as from size DHTG-140 also with overload protection). When the

compressed air ports are pressurised alternately, two toothed rod

pistons move backwards and forwards. By means of a pinion, the

pistons convert the linear movement into a rotary movement.

A second pair of pistons controls the engagement of the pinion in

the table gearing and the locking of the holding position. The

integrated shock absorber brakes the rotary indexing table in the

direction of rotation.

Fig. 2

The DHTG rotary indexing table is intended for turning the work load by a defined angle into a holding

position.

3

Transport and storage

•

Take the weight of the DHTG into consideration. It weighs up to 25 kg.

•

Ensure the following storage conditions are met:

–

Short storage times and

–

Cool, dry, shaded, corrosion-resistant storage locations.

4

Requirements for product use

Note

Improper handling can result in malfunctions.

•

Be sure to always comply with the specifications in this chapter.

•

Compare the maximum values specified in these operating instructions with those of your actual

application (e. g. forces, torques, temperatures, masses, speeds).

Only compliance with the load limits allows operation of the product in compliance with the relevant

safety regulations.

•

Take into consideration the ambient conditions at the location of use.

Corrosive environments reduce the service life of the DHTG.

•

Ensure that there is a supply of correctly prepared compressed air.

•

Maintain the selected medium for the complete service life of the product.

Example: Always use non-lubricated compressed air.

•

Pressurise your entire system slowly.

This will prevent uncontrolled movements from occurring.

For slow start-up pressurisation use safety start-up valve type HEL.

•

Comply with the regulations of the trade association, the German Technical Control Board or

relevant national regulations.