7 operation, 7operation – Festo DHTG User Manual

Page 30

DHTG

30

Festo – DHTG – 1404d English

For setting the cushioning:

•

Loosen the clamping element (K) one rotation.

•

Screw in the adjusting screw

6 until the desired cushioning

is achieved. The rotary indexing table must

not strike hard

against the end stops and the overload protection must not

be triggered. The maximum moment of mass inertia must

not be exceeded.

6

(K)

Fig. 11

Adjusting screw direction of rotation

6

Reaction

Clockwise

1)

Cushioning is increased

Anti-clockwise

Cushioning is reduced

1)

Screw in the adjusting screw until it is flush

Tab. 14

•

Tighten the clamping element (K) again.

Tightening torque

Size

65

90

140

220

Width across flats

2.5

2.5

4

4

Tightening torque

[Nm]

0.8

0.8

2.5

2.5

Tab. 15

7

Operation

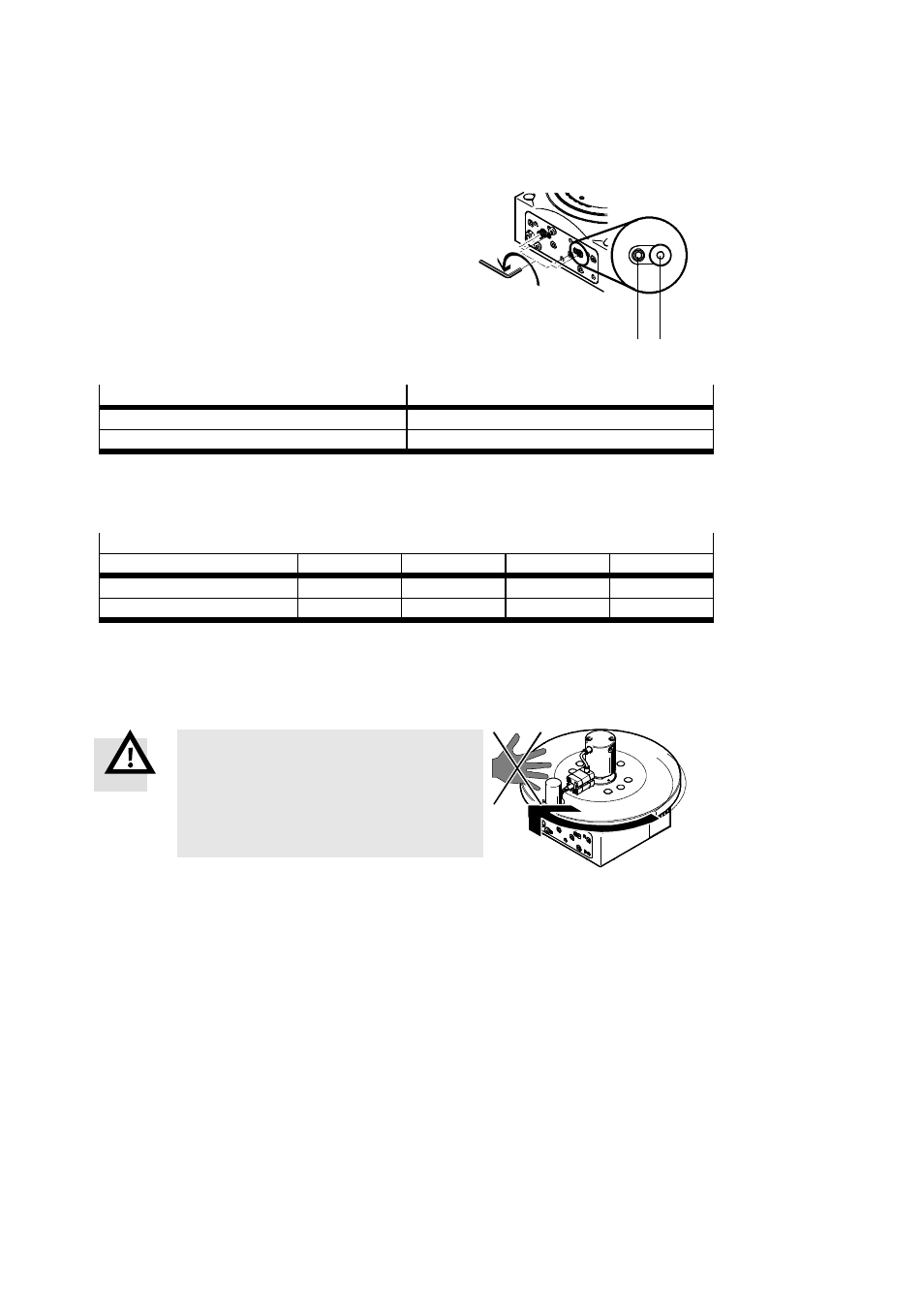

Warning

Risk of injury from rotating masses.

•

Make sure nobody can place his/her hand in

the positioning range of the DHTG and that

no objects lie in its path (e. g. by providing a

protective screen).

•

Note the moment of mass inertia as a factor of the switching or cycle frequency (

Characteristic

curves).

–

The maximum achievable switching frequency as a factor of the moment of mass inertia can be

read in the diagram

Switching frequency. The switching time can be calculated from this

by T = 60/f. The response time comprises:

Switching time = unlocking, turning, locking and the

return stroke of the work piston.

Fig. 12