0 clamp arm machining specifications – Enerpac ST-202 User Manual

Page 8

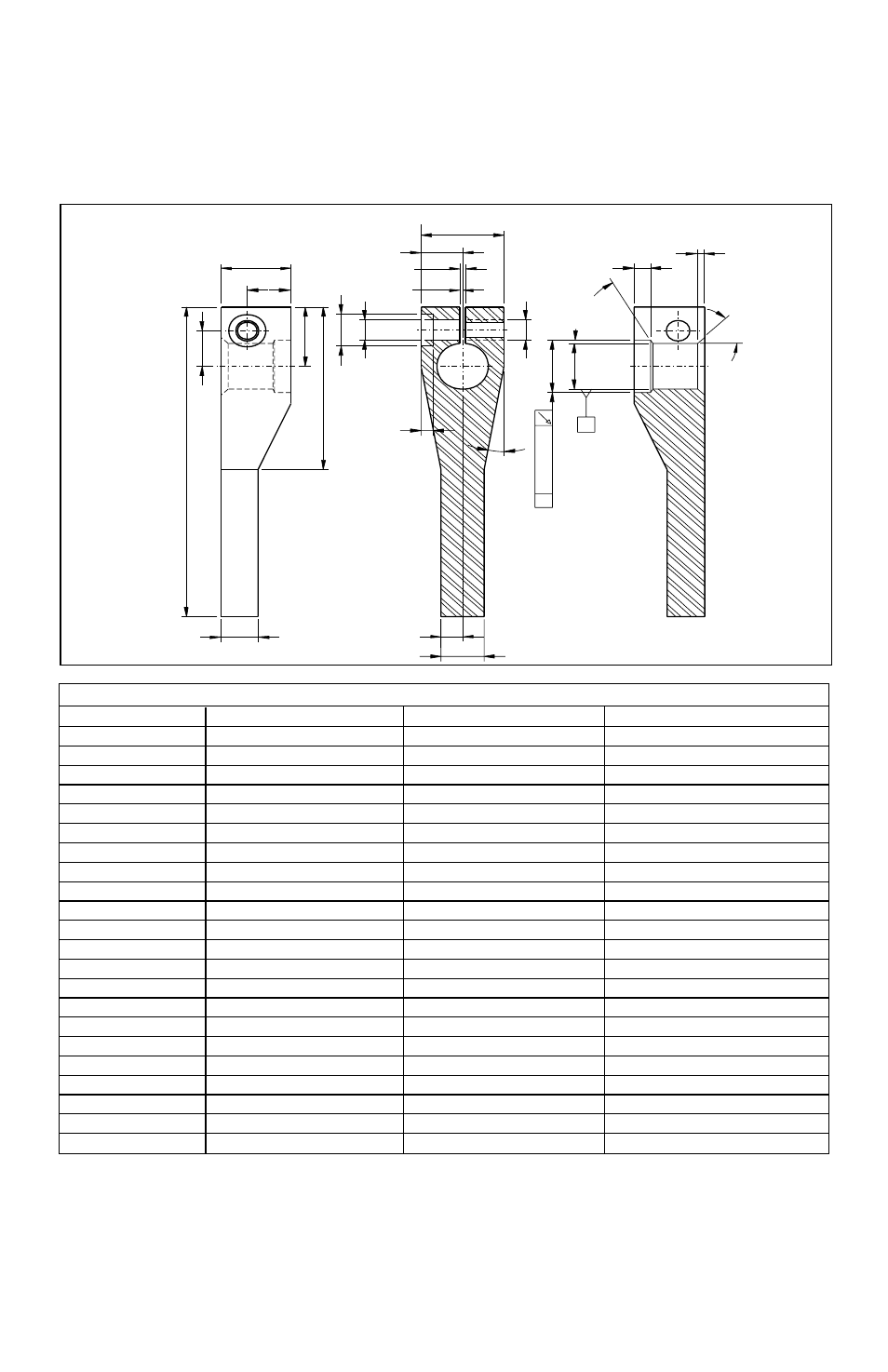

10.0 CLAMP ARM MACHINING

SPECIFICATIONS

Note:

See Pressure and Flow Rate on page 7 to

correctly measure the arm length. To determine the

maximum clamping force for the arm, refer to

Clamping Force -v- Arm Length Graphs on page 3.

8

Dimensions are in mm (in.).

9,0 kN (2024 lb)

18,8 kN (3900 lb)

35,0 kN (7600 lb)

"A"

25 (0.99)

30 (1.18)

40(1.58)

"B" Max.

200 (7.88)

215 (8.47)

224 (8.83)

"C"

40 (1.58)

60 (2.36)

70 (2.76)

"D"

16 (0.63)

21 (0.83)

34 (1.34)

"E"

22 (0.87)

25 (0.99)

30 (1.18)

"F"(3 places)

86 (3.38)

107 (4.22)

114 (4.49)

"G"

30 (1.18)

35 (1.38)

40 (1.58)

"H"

12,5 (0.49)

15 (0.59)

20 (0.79)

"J"

20 (0.79)

30 (1.18)

35 (1.38)

"K" (Dia.)

Ш 14 (0.55)

Ш 17 (0.67)

Ш 17 (0.67)

"L"

9 (0.35)

11 (0.43)

11 (0.43)

"M" (Dia.)

Ш 9 (0.35)

Ш 11 (0.43)

Ш 11 (0.43)

"N" (Thru)

M10 x 1.25

M12 x 1.25

M16 x 1.50

"P"

9 (0.35)

12,8 (0.50)

15 (0.59)

"Q"

18 (0.71)

25,5 (1.00)

30 (1.18 )

"R" 11°-12°

9°-10°

16°-17°

"S" (Dia.)

Ш 27,85-27,95

Ш 35,50-35,60

Ш 41,50-41,60

(1.097-1.101)

(1.399-1.402)

(1.635-1.638)

"T" (Dia.)

Ø 25 H8

Ø 32 H8

Ø 38 H8

(0.9848-0.9858)

(1.2604-1.2614)

(1.4965-1.4975)

"U"

3,9-4,2 (0.15-0.17)

5,1-5,5 (0.20-0.22)

4,9-5,3 (0.19-0.21)

"V"

2,8-3,3 (0.11-0.13)

2,8-3,3 (0.11-0.13)

2,8-3,3 (0.11-0.13)

55˚-60˚

"U"

"T"

"S"

0,08 [.003]

A

A

63P [1,6]

1,1-1,5 [.04-.06]

2,1-3,0 [.08-.12]

"J"

"L"

"P"

"M"

"K"

"N"

"D"

"H"

"A"

"G"

"E"

"B"

"Q"

40˚-50˚

"V"

"C"

“F”

3-places

“R”

2

-places