Enerpac ST-202 User Manual

Page 6

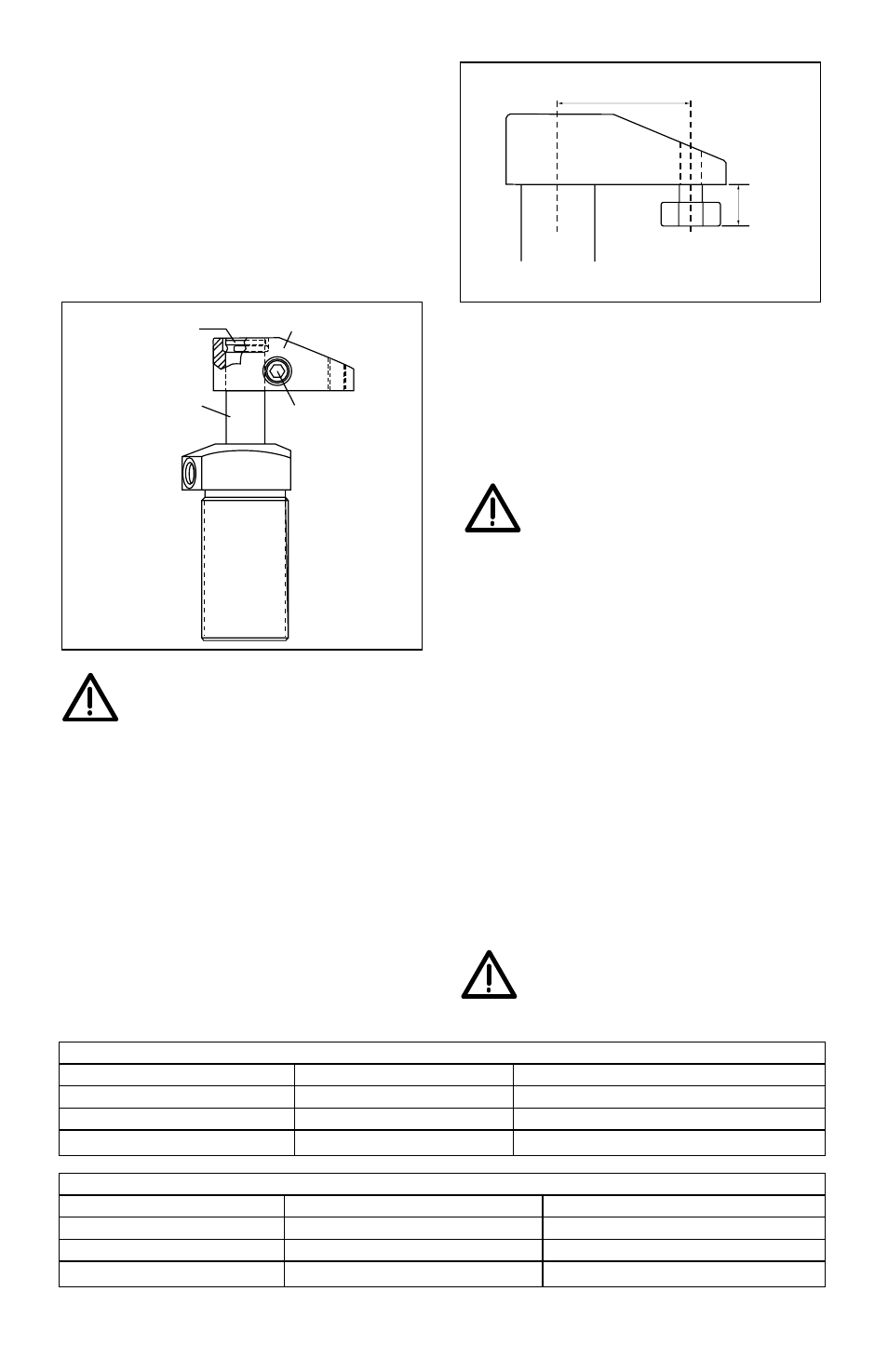

6.4 Attaching Clamp Arm

1. Remove the retaining ring from the top of the plunger.

2. Slide the clamp arm down over the plunger and use

a pliers to push the retaining ring back onto the

plunger groove. Orient the retaining ring so the

retaining ring gap will face the back of the clamp arm.

See illustration.

3. Move the clamp arm up until it is firmly against the

retaining ring and in the desired position. While

maintaining this position, torque the clamp arm bolt

to specification listed below.

CAUTION:

Inadequate torquing of the

clamp arm bolt could cause the arm to slip

during operation. BE SURE TO USE QUALITY

12.9 DIN 912 (GRADE 8) SOCKET HEAD CAP SCREWS

(supplied with standard clamp arms).

6.5 Arms for Upper Flange Body Style

To use the upper flange body style cylinders, you have to

be sure that the contact bolt head will clear the upper

flange during operation. The clamp arm must be long

enough for the bolt head to clear the upper flange as the

arm swings down. Clearance problems are most

common when using the CAS series standard length

arm, with the final clamping position at the side of the

cylinder. You may need to use the longer CAL Series

clamp arm for these applications. You can cut CAL series

arms to meet your own requirements, or make your own

custom arms according to the dimensions on page 8.

7.0 OPERATION

Swing cylinders rotate 90° during the first portion of

the stroke, continuing without rotation for the final

clamping stroke. The straight downward stroke is the

clamping stroke of the cylinder. Clamping force must

be applied only during the vertical travel, not during

the swing motion.

CAUTION:

— If clamping force is applied

during the rotation portion of the stroke,

internal plunger damage may result.

— To ensure maximum cylinder performance and

safety, be sure all hydraulic connections, hoses,

and fittings are properly sealed and fully

tightened.

— Be sure all items are rated to withstand system

pressures. Under-rated components will not

withstand higher pressure. Using under-rated

components will lead to equipment damage and

possible personal injury.

7.1 Turning Mechanism Protection

The kick-out turning mechanism protection is

designed to help prevent internal cylinder parts from

damage caused by obstructed plunger movement,

workpiece-clamp arm collision, and excessive oil

flow. If the kick-out mechanism activates, release

system pressure, check for the cause of the

activation and correct the problem. Return the

cylinder to its original position by hand or by using a

wrench.

CAUTION: After the kick-out mechanism

has been activated, always release the

hydraulic pressure in your system before

returning the mechanism to its original position.

6

Clamp Arm Bolt Torque

Cylinder Capacity

Bolt Type

Torque

9,0 kN (2024 lbs)

M10 x 1.25 x 35

81-95 Nm (60-70 ft-lbs)

18,8 kN (3900 lbs)

M12 x 1.25 x 40

95-108 Nm (70-80 ft-lbs)

35,0 kN (7600 lbs)

M16 x 1.50 x 55

217-244 Nm (160-180 ft-lbs)

Maximum Contact Bolt Length

Cylinder Capacity

Maximum Bolt Length

CAS Series Arm

9,0 kN (2024 lbs)

18 mm (0.71”)

L - 45 mm (1.77”)

18,8 kN (3900 lbs)

22 mm (0.875”)

L - 55 mm (2.17”)

35,0 kN (7600 lbs)

24 mm (1.00”)

L - 68 mm (2.68”)

Retaining ring

Clamping arm

(Opening toward

back of clamp arm)

Plunger

Clamp arm bolt

L

Contact bolt

(with head dia.

larger than 16mm [.63])

Max.

length