5 mounting upper and lower flange cylinders – Enerpac ST-202 User Manual

Page 4

5.0 MOUNTING SPECIFICATIONS

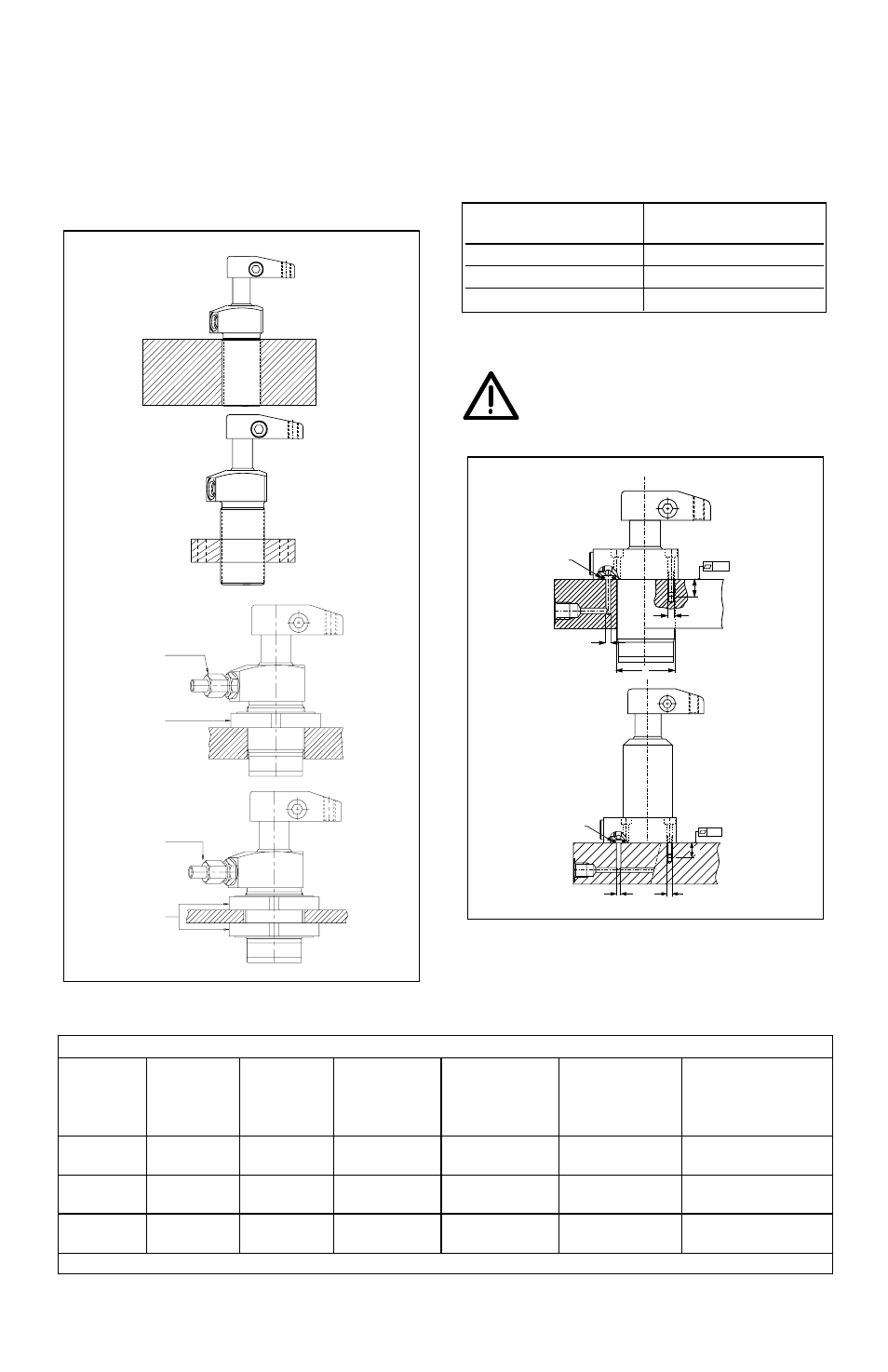

5.1 Mounting Threaded Body Cylinders

Threaded body cylinders can be threaded into a tapped

hole, secured to the fixture using a mounting flange,

threaded into the fixture and secured with a jam nut, or

mounted through a clearance hole and secured with jam

nuts. See illustrations below.

When a threaded body style swing cylinder is being

installed in a fixture, the thread engagement should be

no less than the thread engagement for the standard

Enerpac mounting flange. If a cylinder is being mounted

using just the lower portion of the threads, the

engagement should be increased for additional support.

See table below for minimum thread engagement.

5..2 Mounting Upper and Lower Flange Cylinders

WARNING: The fixture must be capable of

withstanding 350 bar (5,000 psi) hydraulic

working pressure when the cylinders are

manifold mounted.

Cylinder Capacity

Minimum Thread

Engagement

9,0 kN (2024 lb)

16 mm (0.63")

18,8 kN (3900 lb)

25 mm (1.00")

35,0 kN (7600 lb)

30 mm (1.25")

4

Manifold Specifications

Cylinder

Max. Oil

Fixture

Mounting

Minimum

Lubricated

Manifold

Capacity

Channel

Hole

Threads

Thread

Mounting

O-Ring

Diameter

Diameter

Depth

Bolt Torque

Dimensions

Ø A

Ø B

C

D

I.D. x w

9,0 kN

4mm

49,1± 0,8

M6x30

15 mm

13,5-15 Nm

4,34 x 3,56mm

2024 lb

0.156"

1.93± .03

0.59"

10-11 ft-lbs

0.171 x 0.139"

18,8 kN

0.156"

63,4± 0,4

M8x30

15 mm

32-38 Nm

4,34 x 3,56mm

3900 lb

4 mm

2.50 ± .02

0.59"

25-30 ft-lbs

0.171 x 0.139"

★ 35,0 kN

0.156"

77,5± 0,3

M10x30

15 mm

65-72 Nm

4,34 x 3,56mm

7600 lb

4mm

3.05 ± .01

0.59"

48-53 ft-lbs

0.171 x 0.139"

★ includes. long stroke

Threaded into

fixture

Mounting

flange

Oil connection

Jam nut

Jam nuts

Oil connection

Manifold

O-ring

Manifold

O-ring

0.003

0.003

A

B

C

D

A

C

D