Dakota Ultrasonics DFX-8 plus MANUAL1 User Manual

Page 58

54

CHAPTER SIX

TRIGONOMETRY MODE

6.1 Introduction to TRIG

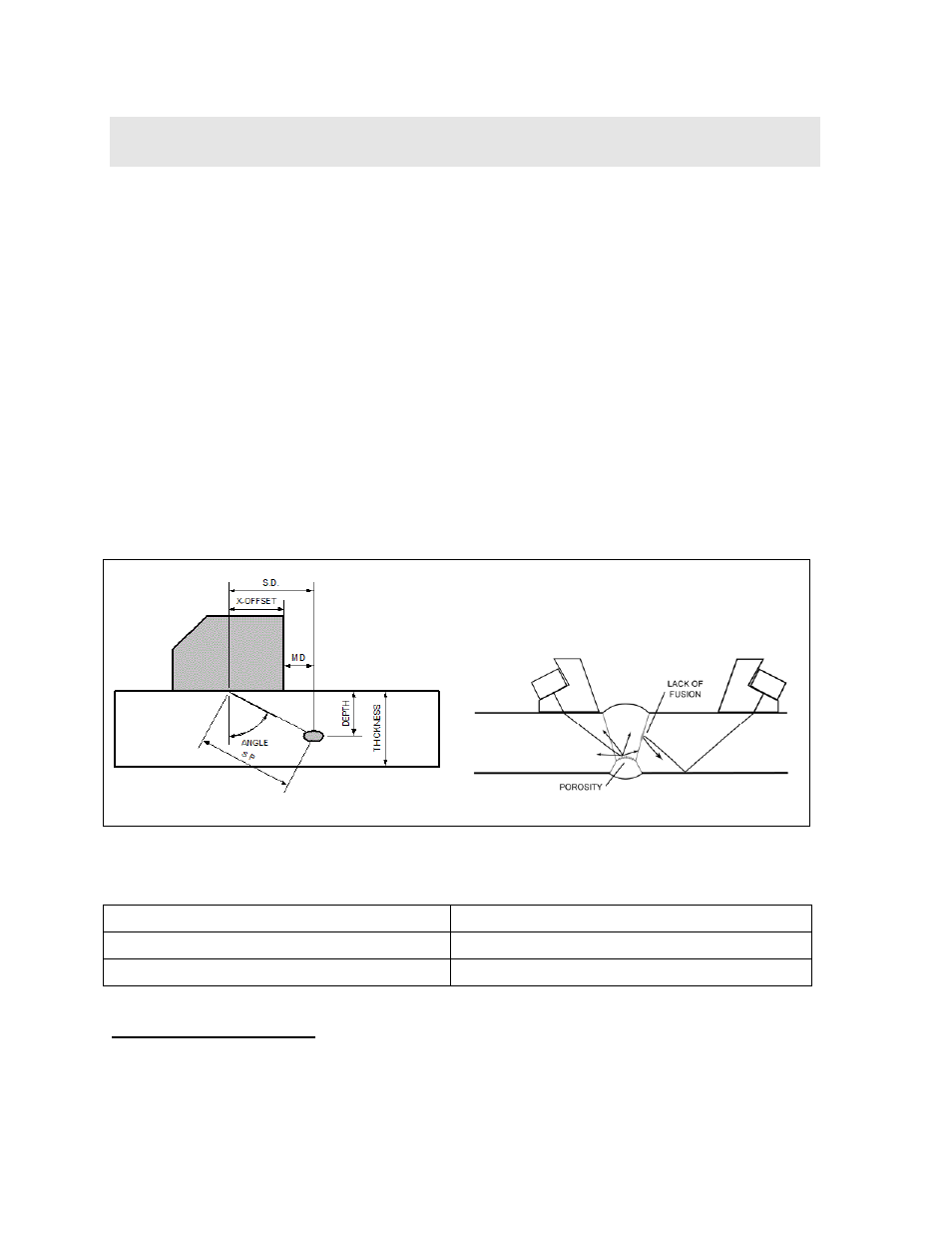

Trig mode is most commonly used for inspecting welded joints using an angle beam

transducer. Based on the location, orientation, and geometry of the weld, a straight

beam transducer is typically not suitable for inspection. As a result, a transducer

emitting sound at a given angle will allow the operator to position the transducer

away from the actual weld, and “skip” into the weld at a given angle. Therefore, in

order to determine the location of a defect, given a specific angle, the trigonometry

mode is used. This section will cover the steps to setup and utilize trigonometry

mode.

6.2 Additional Comments

Prior to proceeding on to the next section outlining how to enable and setup the TRIG

mode, a few additional items should be clarified:

Angle Beam Transducer Weld Inspection

Refer to the Angle Beam Transducer diagram above:

SP – Sound Path

X-Offset – Front of wedge less Index

Angle – Transducer Angle

SD – Surface Distance

Thickness – Material Thickness

Depth – Depth of flaw from surface

Screenshot Trig mode: