Dakota Ultrasonics DFX-8 plus MANUAL1 User Manual

Page 49

DFX-8 Series Ultrasonic Flaw Detectors

45

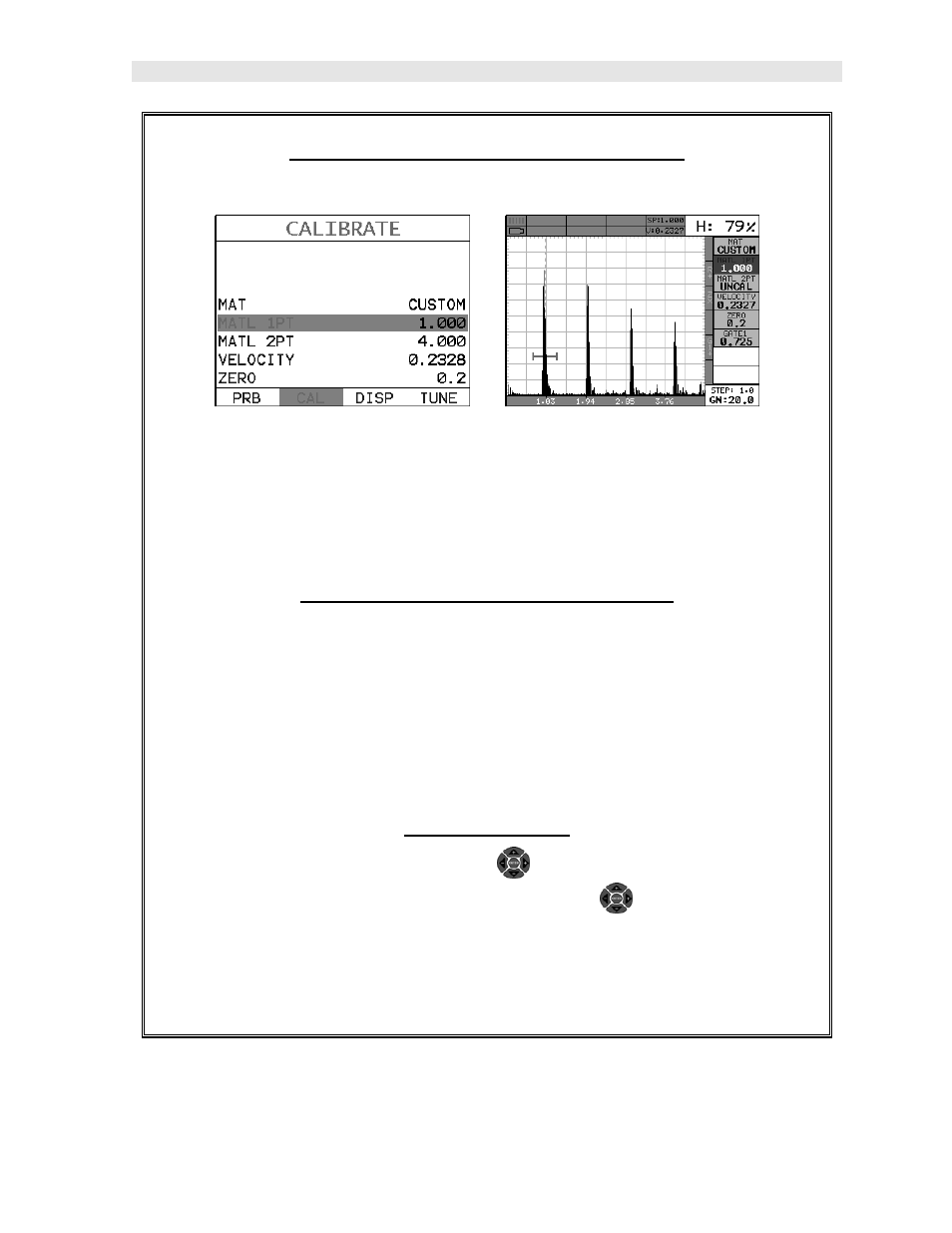

Two Point Calibration – Straight Beam

Note: Calibration standards representing the minimum and maximum

thickness of the overall inspection range intended are required. They must also

be of the same material type as the intended application. For our example,

we’ll be using a 1 and 4 inch standard for calibration.

Coupling to the 1” Cal Standard (1

st

Point)

Apply a drop of couplant on the transducer and place the transducer in steady

contact with the 1” calibration standard. Be sure that the reading is stable and

the repeatability indicator, in the top left corner of the display, is fully lit and

stable. Also, be sure there is sufficient signal amplitude in order to avoid ‘peak

jumping’ or missing the first cycle.

Adjusting the Gate

1) Using the left button wheel, press the

LEFT and RIGHT arrow keys to

scroll through the 9 individual Hot Menus, and the

UP and DOWN arrow

keys to scroll through the Hot Menu items, until the GATE1 cell is

highlighted. Alternatively, the MEAS & ESC keys can be used to scroll

through the Hot Menu items.