Dakota Ultrasonics DFX-8 plus MANUAL1 User Manual

Page 54

Dakota Ultrasonics

50

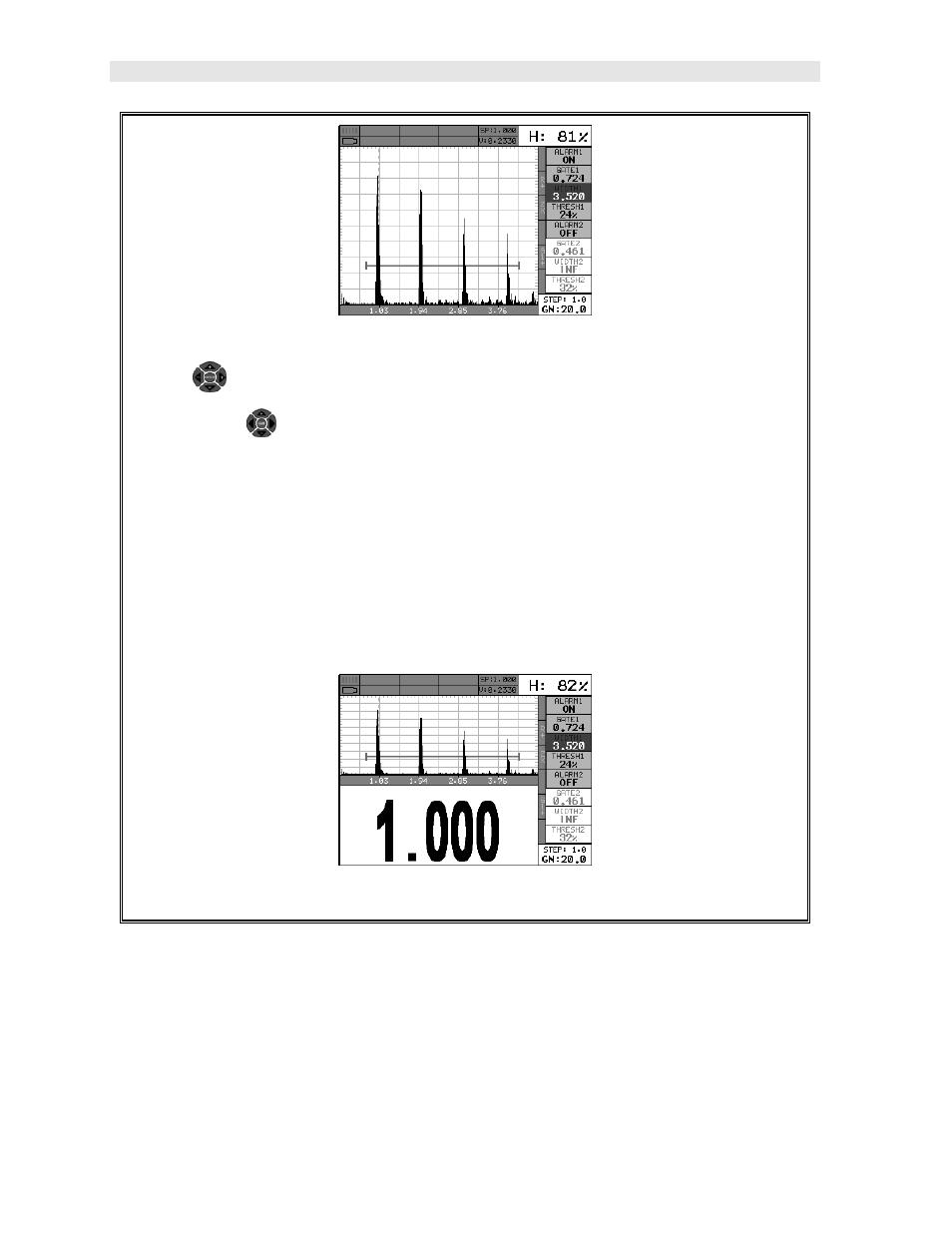

3) Press the MEAS key once to highlight the WIDTH1 cell. Alternatively, use

the

UP and DOWN arrow keys on the left button wheel

4) Press the

LEFT and RIGHT

arrow keys on the right button wheel to

move the gate start to a position greater than 4 inches.

Note: CHECK YOUR CALIBRATION! Place the transducer back on the one

inch point, and any others in the given range, to confirm linearity. If the velocity

and zero values we calculated correctly, the thickness reading will match the

known thickness of the calibration standards. If the thickness is not correct,

repeat the steps above.

5) Press the OK key once to display the split screen with the thickness value.

5.3 Angle Beam Calibration

In the first example we demonstrated how to perform a two point calibration using a

single element straight beam contact transducer. With the exception of a handful of

additional comments, calibration using an angle beam transducer is virtually identical

in the scope of the overall step by step process. To avoid copying the procedures

from the previous section, we’ll focus only on the additional comments. Refer to