Dakota Ultrasonics DFX-8 plus MANUAL1 User Manual

Page 109

DFX-8 Series Ultrasonic Flaw Detectors

105

Immersion Testing

Considerations:

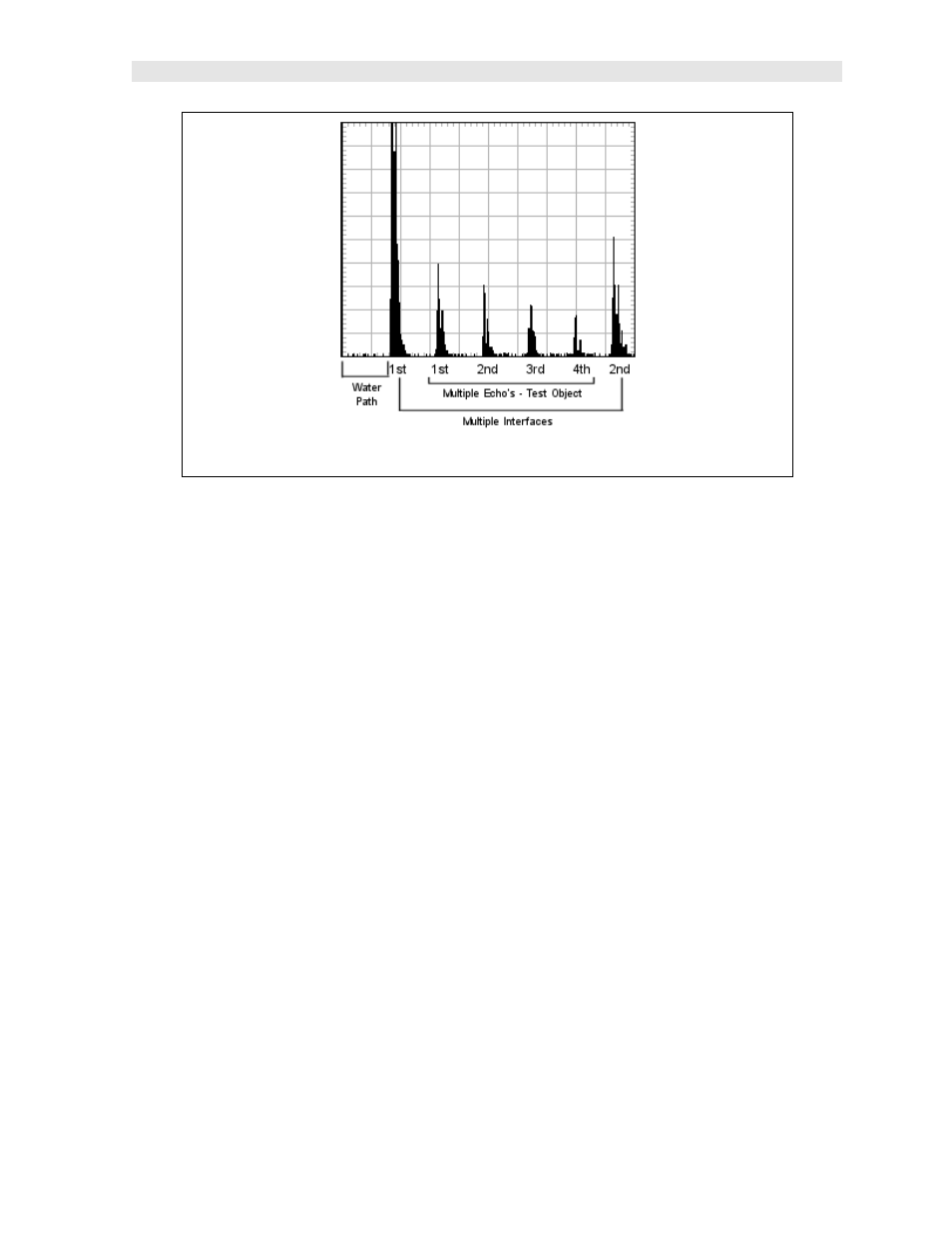

There is a significant difference between sound traveling in water versus steel,

for example. The longitudinal velocity of sound traveling through water is

approximately 0.058 in/µs, while 0.2320 in/µs in steel. Since the DFX-8+ has

been setup and calibrated for a steel test object, this would find the water path

interface at approximately 4”, considering an actual 1” water path, or 4 times

the depth/distance on the calibrated display.

It is recommended that the water path be greater than 25% of the thickness of

the test object, and that the water path is long enough to keep the flaw

evaluation process beyond the “near zone” and entirely in the “far zone” where

sound has achieved the most uniform wave front (near zone will be contained

in the water path).

Additionally, any movements of the transducer or test object that change the

water path distance are then compounded by a factor of 4x. Therefore, a

mechanical fixture or carriage is typically used on the top side of the tank in

order to maintain the positioning of the transducer to the test object.

Changes in the targets angle and water path distance will reduce the

amplitude/output, and should be considered during the evaluation of a flaw.

Obviously, the optimal evaluation would be a perfectly fixed transducer

position with a perfectly parallel reflector and water path distance.