Cluster gear punch marks -17 – JLG 460SJ ANSI Service Manual User Manual

Page 71

SECTION 3 - CHASSIS & TURNTABLE

3120788

– JLG Lift –

3-17

9. With large splined end down, place input shaft sub-

assembly (7) into spindle (1A).

10. Place thrust spacer (9) onto input shaft (7).

11. Set carrier sub-assembly (3) on a flat work surface

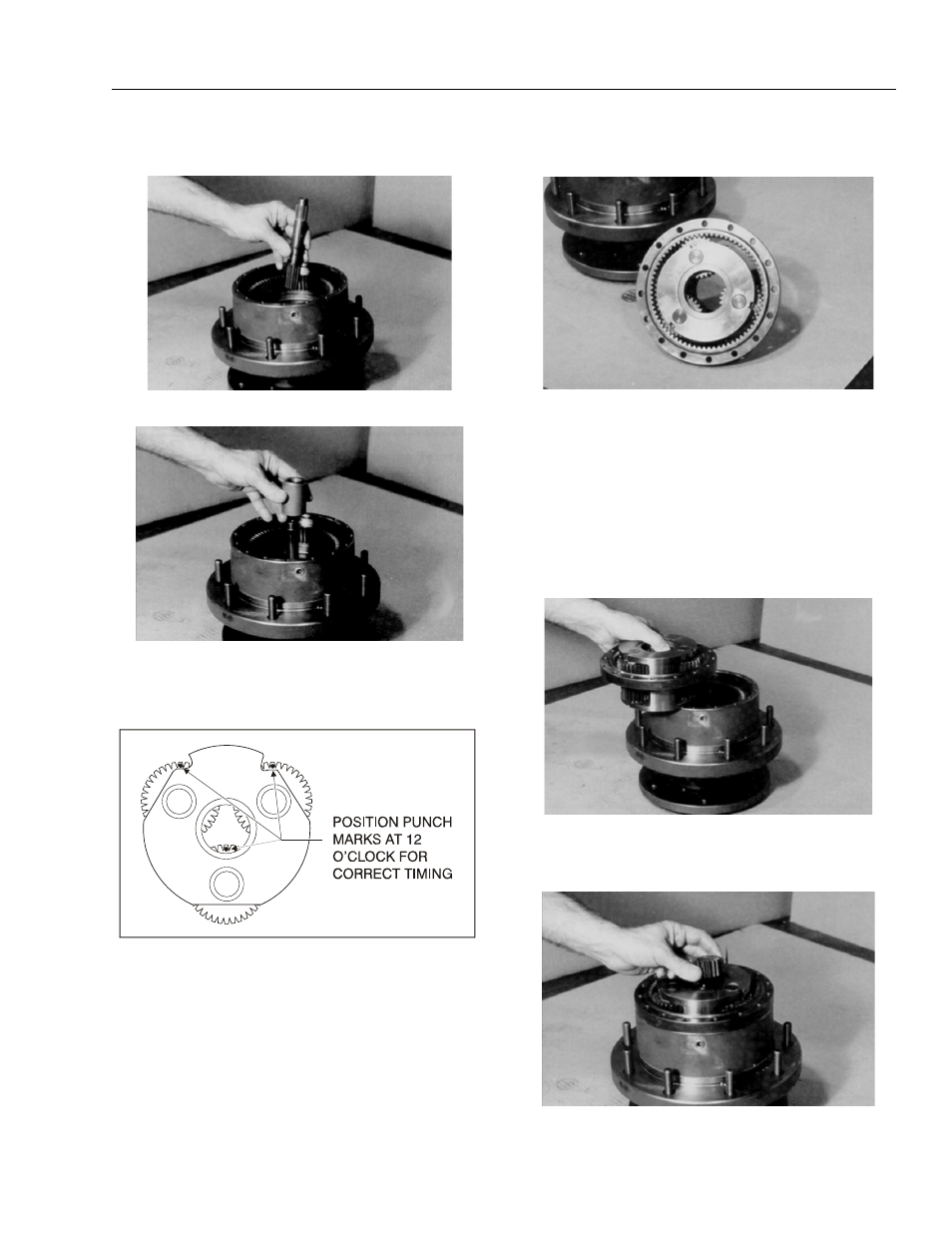

so the large ends of cluster gears (3F) face up.

Locate the punch marks on the face of each cluster

gear (3F) and position them at 12 o’clock.

12. With "X" marked side facing up, place the ring gear

(4) around cluster gears (3F).

NOTE: This will hold the punch marks in position while

installing the carrier into the hub.

13. Place the carrier sub assembly (3) and ring gear (4)

together into mesh with internal gear (2), aligning

the "X" marked shoulder bolt hole in the ring gear (4)

over one of the shoulder bolt holes in the hub. Mark

the location of shoulder bolt holes on the outside of

ring gear and hub.

NOTE: You may lift the ring gear off the hub to align the

shoulder bolt holes. The ring gear and carrier are

installed together only to keep the punch marks on

the carrier in place.

14. With the internal splines facing up (counterbore end

facing down), place input gear (8) into mesh with

carrier sub-assembly (3).

Figure 3-3. Cluster Gear Punch Marks