JLG 460SJ ANSI Service Manual User Manual

Page 110

SECTION 3 - CHASSIS & TURNTABLE

3-56

– JLG Lift –

3120788

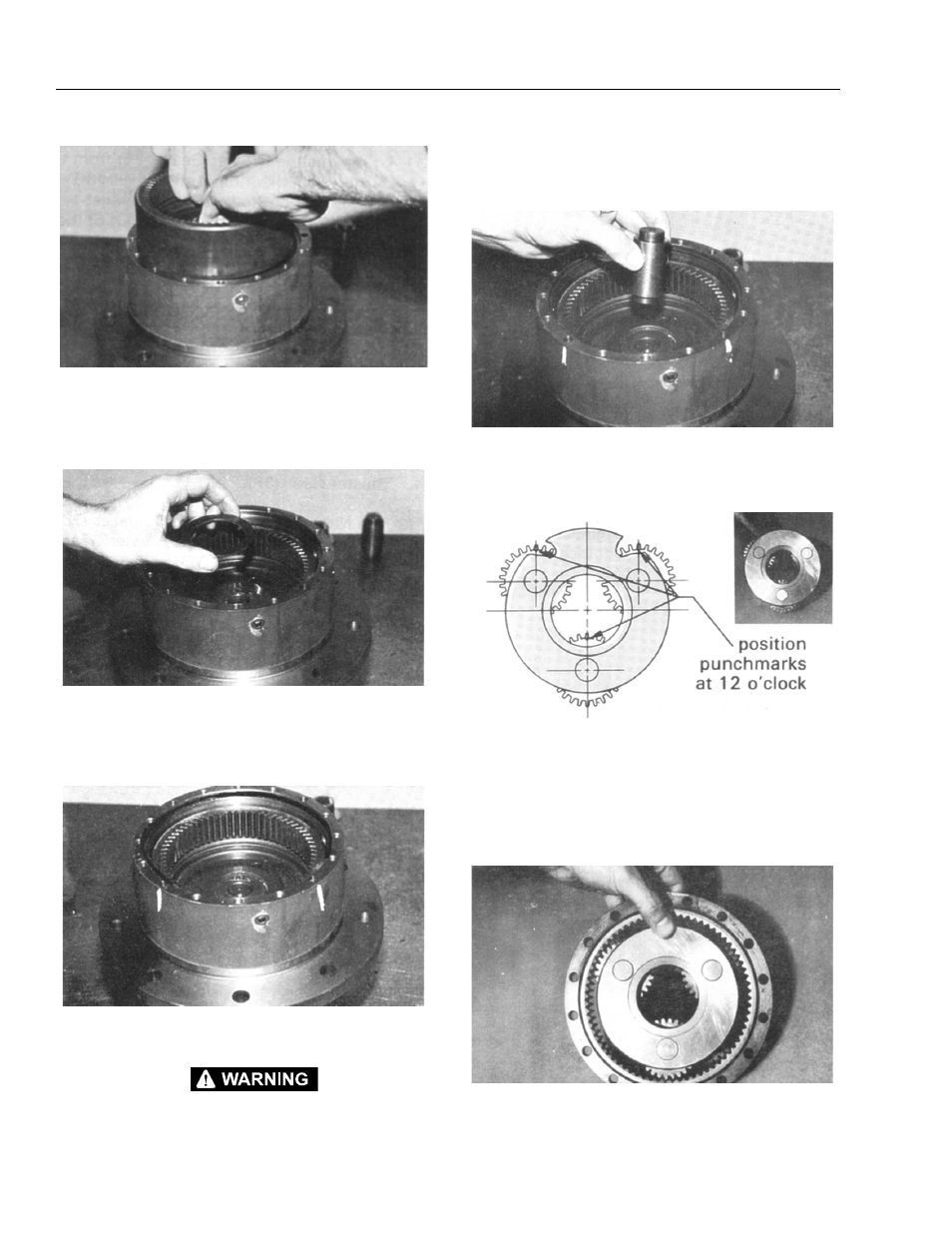

14. With the Hub Shaft Sub assembly resting on the

Shaft (1A), install Internal Gear (2). The Spline of the

Internal Gear (2) will mesh with the spline of the Out-

put Shaft (1A).

15. Thrust Washer (11) is installed on the face of the

Output Shaft (1A). Sufficient grease or petroleum

jelly should be used to hold thrust Washer (11) in

place.

16. Place “O” Ring (5) into Hub counterbore. Use petro-

leum jelly to hold “O” Ring in place.

BEWARE OF SHARP EDGES OF THE COUNTERBORE WHILE SEAT-

ING THE “O” RING.

Also at this time locate and mark the 4 counter

beamed holes in the face of the Hub (1G). This is for

Identification later in the assembly.

17. Thrust Spacer (9) is installed into the bore of the

Output Shaft (1A). This should be a slip fit and the

Thrust Spaces should rotate in this location.

18. Place Carrier Assembly (3) on a flat surface with the

large gears (3F) up and positioned as shown. Find

the punch marked tooth on each large gear (3F) and

locate at 12 o’clock (straight-up) from each planet

pin. Marked tooth will be located just under the car-

rier (3A) on upper two gears (3F).

19. With shoulder side of Ring Gear (4) facing down,

place Ring Gear over (into mesh with) large gears.