Gerotor end, Gerotor end -22 – JLG 460SJ ANSI Service Manual User Manual

Page 312

SECTION 5 - HYDRAULICS

5-22

– JLG Lift –

3120788

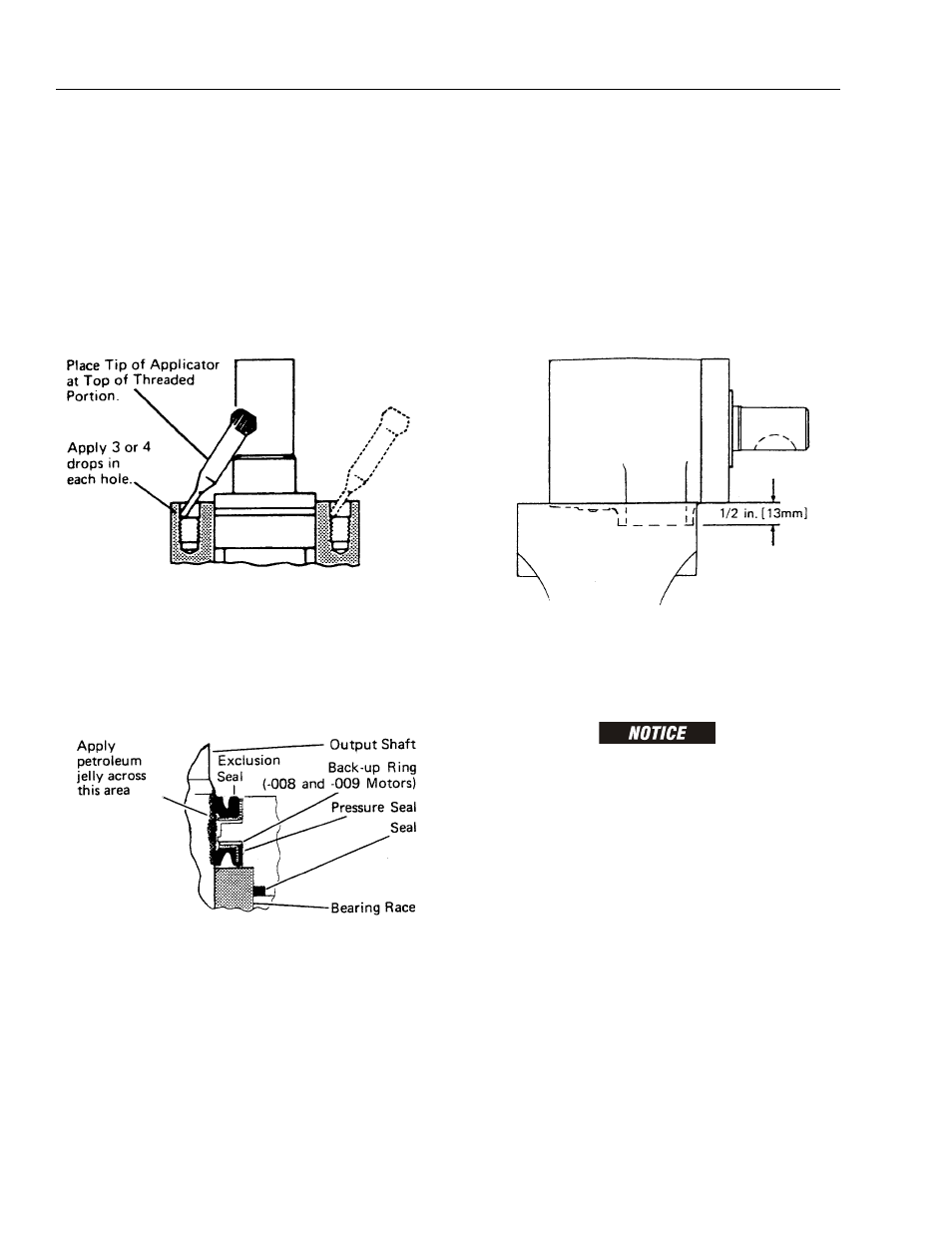

9. Apply 3 or 4 drops of Loctite sealant at top of thread

for each of four holes in housing.Do not allow parts

with Loctite applied to come in contact with any

metal parts other than those for assembly. Wipe off

excess Loctite from housing face, using a non -

petroleum base solvent.

Do not apply Loctite to threads more than 15 min-

utes before installing screws. If housing for more

than 15 minutes, repeat application. No additional

cleaning or removal of previously applied Loctite is

necessary.

10. Before installing flange and seal assembly over

shaft, place protective sleeve or bullet over shaft.

Then lubricate space between exclusion seal and

pressure seal, as well as lips of both seals.

Install flange. Rotate flange slowly while pushing

down over shaft. Be careful not to invert or damage

seals.

11. After removing bullet, clamp motor in vise as shown

in Figure 2-49. Make sure shaft cannot fall out. Install

dry screws and alternately torque them immediately

to 250 in-lbs (28 Nm). If you use primer, allow to cure

for 10 to 15 minutes. Without primer, allow 6 hours

curing time before subjecting motor to high torque

reversals. On all other applications, you can run

motor immediately.

If you use new screws, make sure they are the cor-

rect length: 7/8 in. (22mm) under head length. See

parts list for correct part number.

Gerotor End

1. Reposition motor with gerotor end up, then clamp

across ports. Do not clamp on side of housing.

TO AID INSTALLATION OF SEALS, APPLY LIGHT COAT OF CLEAN

PETROLEUM JELLY TP SEALS. DO NOT STRETCH SEALS BEFORE

INSTALLING THEM IN GROOVE.

2. Pour approximately 35 cc of clean hydraulic oil in

output shaft cavity.

3. Install 2 7/8 in. (73 mm) I.D. seal in housing seal

groove. Avoid twisting seal.