JLG 460SJ ANSI Service Manual User Manual

Page 111

SECTION 3 - CHASSIS & TURNTABLE

3120788

– JLG Lift –

3-57

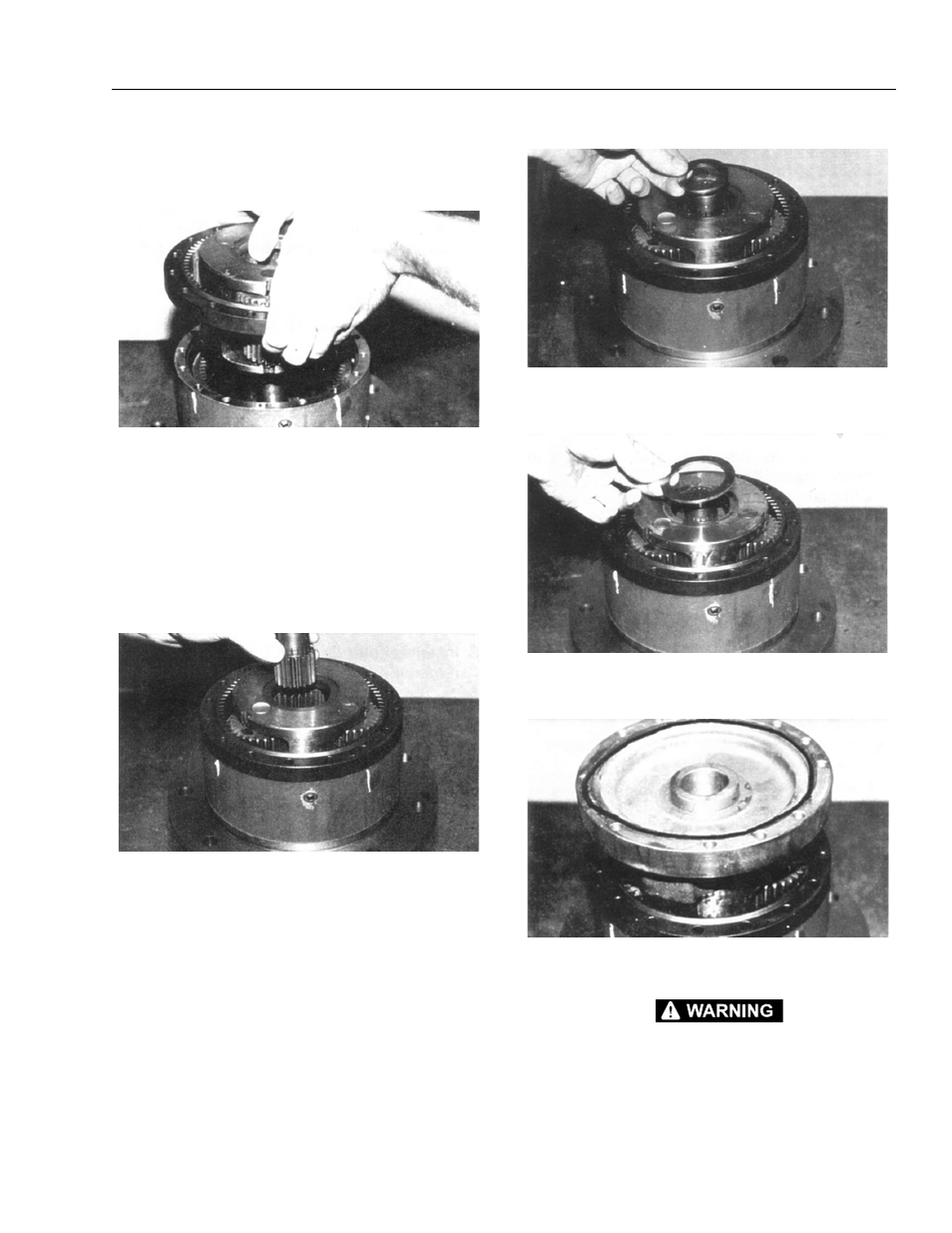

Be sure that punch marks remain in correct location

during Ring gear installation. The side of the Ring

Gear with “X” stamped on it should be up.

20. While holding Ring Gear (4) and Cluster Gear (3F) in

mesh, place small side of Cluster Gears (3F) into

mesh with the Internal Gear (13). On the Ring Gear

locate the hole marked “X” over one of the marked

counterbored holes (step 3) in Hub (1G).

NOTE: If gears do not mesh easily or Carrier Assembly

does not rotate freely, then remove the Carrier and

Ring Gear and check the Cluster Gear timing.

21. Input Gear (8) is installed, meshing teeth of the large

diameter Cluster Gear (3F). The counterbore on the

Input Gear (3F). The counterbore on the Input Gear

(8) locates on the shoulder of the Thrust Spacer (9).

This is to be a slip fit and operate freely.

22. Thrust Washer (10) is installed onto the Input Gear

(8) and should locate on the gear teeth shoulder.

23. Thrust Washer (11) is installed into the counterbore

of the Carrier (3).

24. Place “O” Ring (5) into cover (6) counterbore. Use

petroleum jelly to hold “O” Ring in place.

BEWARE OF SHARP EDGES OF THE COUNTERBORE WHILE SEAT-

ING THIS “O” RING.