3 valves - theory of operation, Solenoid control valve, Valves - theory of operation -14 – JLG 460SJ ANSI Service Manual User Manual

Page 304: Solenoid control valve -14, Holding valve torque specification -14

SECTION 5 - HYDRAULICS

5-14

– JLG Lift –

3120788

NOTE: If applicable, install the cartridge-type holding valve

and fittings in the rod port block, using new o-rings

as applicable. (See Table 5-2, Holding Valve Torque

Specification.)

Table 5-2. Holding Valve Torque Specification.

IF THE CYLINDER IS TO BE TESTED PRIOR TO INSTALLATION ON

THE MACHINE, EXTREME CARE SHOULD BE USED TO INSURE

THAT THE OUTER END OF THE ROD IS SUPPORTED. USE EITHER

A TRAVELING OVERHEAD HOIST, FORK-LIFT, OR OTHER MEANS

TO SUPPORT THE OVERHANGING WEIGHT OF THE EXTENDING

ROD.

5.3 VALVES - THEORY OF OPERATION

Solenoid Control Valve

Control valves used are four-way three-position solenoid

valves of the sliding spool design. When a circuit is acti-

vated and the control valve solenoid energizes, the spool

is shifted and the corresponding work port opens to per-

mit oil flow to the component in the selected circuit with

the opposite work port opening to reservoir. Once the cir-

cuit is deactivated (control returned to neutral) the valve

spool returns to neutral (center) and oil flow is then

directed through the valve body and returns to reservoir. A

typical control valve consist of the valve body, sliding

spool, and two solenoid assemblies. The spool is

machine fitted in the bore of the valve body. Lands on the

spool divide the bore into various chambers, which, when

the spool is shifted, align with corresponding ports in the

valve body open to common flow. At the same time other

ports would be blocked to flow. The spool is spring loaded

to center position, therefore when the control is released,

the spool automatically returns to neutral, prohibiting any

flow through the circuit.

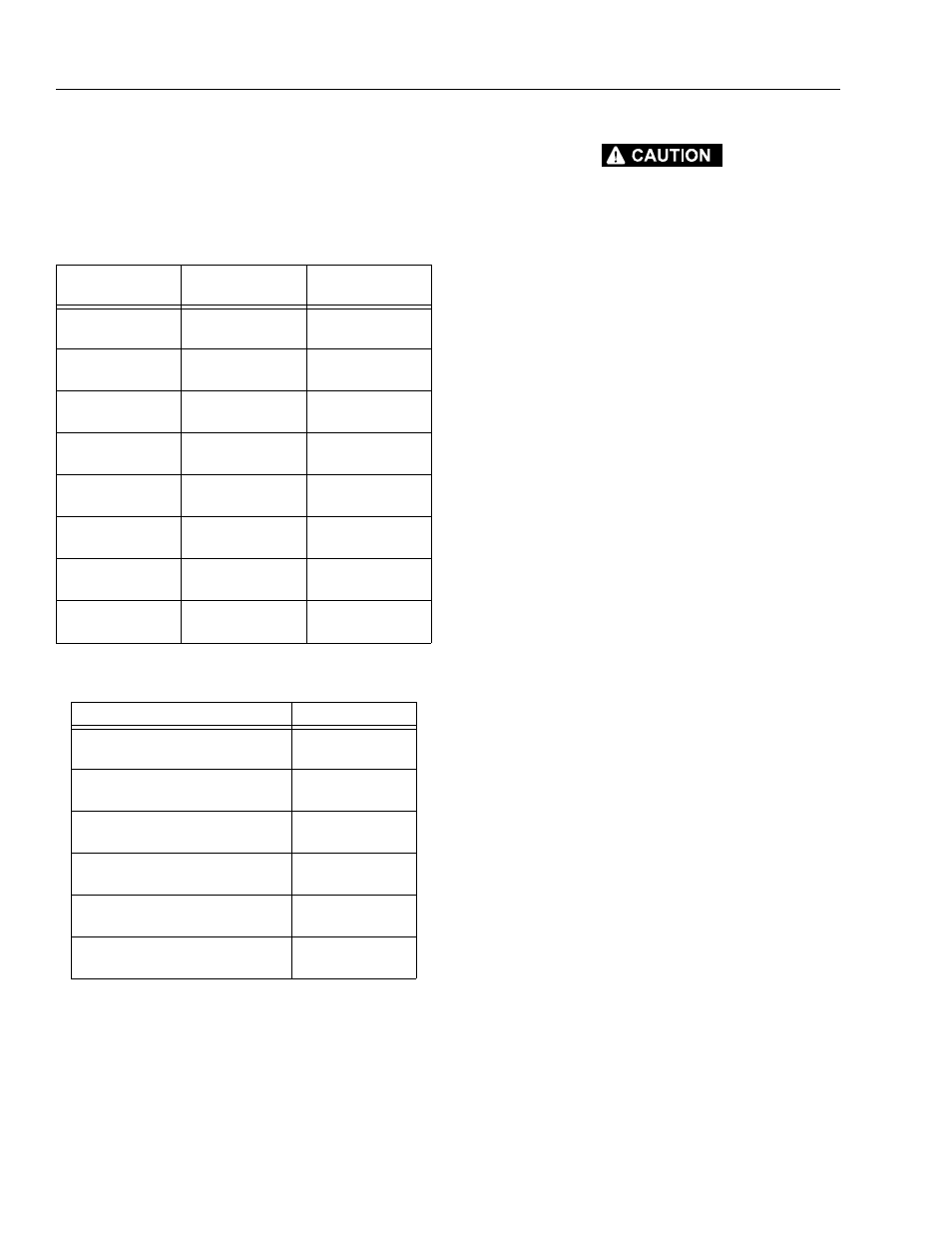

Table 5-1. Cylinder Head and Tapered Bushing Torque

Specifications

Description

Head Torque Value

(Wet)

Tapered Bushing

Torque Value (Wet)

Lift Cylinder

120 ft. lbs.

(162 Nm)

9 ft. lbs

(12 Nm)

Lift Cylinder (SJ)

30 ft. lbs.

(41 Nm)

5 ft. lbs

(7 Nm)

Tele Cylinder

30 ft. lbs

(41 Nm)

9 ft. lbs

(12 Nm)

Level Cylinder

50 ft. lbs.

(68 Nm)

9 ft. lbs

(12 Nm)

Master Cylinder

50 ft. lbs.

(68 Nm)

9 ft. lbs

(12 Nm)

Level Cylinder (SJ)

50 ft. lbs.

(68 Nm)

9 ft. lbs

(12 Nm)

Axle Oscillation

Cylinder

30 ft. lbs.

(41 Nm)

N/A

Steer Cylinder

30 ft. lbs.

(41 Nm)

N/A

Description

Torque Value

SUN - 7/8 HEX M20 x 1.5 THDS.

30-35 ft.lbs.

(41-48 Nm)

SUN - 1 1/8 HEX 1-14 UNS THDS.

45-50 ft.lbs.

(61-68 Nm)

SUN - 1 1/4 HEX M36 x 2 THDS.

150-160 ft.lbs.

(204-217 Nm)

RACINE - 1 1/8 HEX 1 1/16-12 THDS.

50-55 ft.lbs.

(68-75 Nm)

RACINE - 1 3/8 HEX 1 3/16-12 THDS.

75-80 ft.lbs.

(102-109 Nm)

RACINE - 1 7/8 HEX 1 5/8-12 THDS.

100-110 ft.lbs.

(136-149 Nm)