Tapered bushing installation -13, Seating the tapered bearing -13, Poly-pak piston seal installation -13 – JLG 460SJ ANSI Service Manual User Manual

Page 303: Rod assembly installation -13

SECTION 5 - HYDRAULICS

3120788

– JLG Lift –

5-13

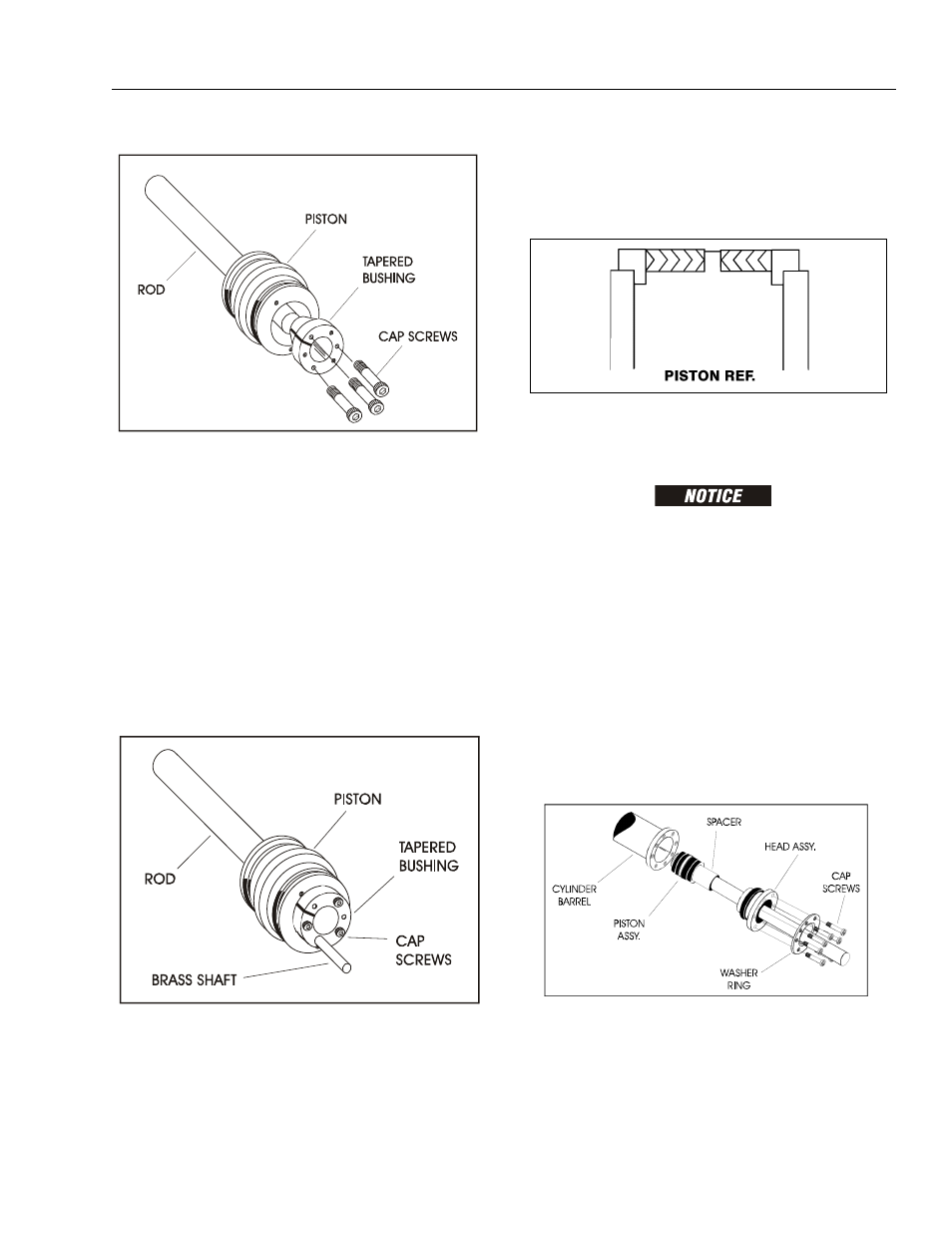

12. Tighten the capscrews evenly and progressively in

rotation to the specified torque value. (See Table 5-1,

Cylinder Head and Tapered Bushing Torque Specifi-

cations.)

13. After the screws have been torqued, tap the tapered

bushing with a hammer (16 to 24 oz.) and brass

shaft (approximately 3/4” in diameter) as follows;

a. Place the shaft against the cylinder rod and in

contact with the bushing in the spaces between

the capscrews.

b. Tap each space once; this means the tapered

bushing is tapped 3 times as there are 3 spaces

between the capscrews.

.

14. Retorque the capscrews evenly and progressively in

rotation to the specified torque value. (See Table 5-1,

Cylinder Head and Tapered Bushing Torque Specifi-

cations.)

15. Remove the cylinder rod from the holding fixture.

16. Place new guide locks and seals in the applicable

outside diameter grooves of the cylinder piston.

(See Figure 5-17., Piston Seal Kit Installation.)

17. Position the cylinder barrel in a suitable holding fix-

ture.

EXTREME CARE SHOULD BE TAKEN WHEN INSTALLING THE CYL-

INDER ROD, HEAD, AND PISTON. AVOID PULLING THE ROD OFF-

CENTER, WHICH COULD CAUSE DAMAGE TO THE PISTON AND

CYLINDER BARREL SURFACES.

18. With barrel clamped securely, and while adequately

supporting the rod, insert the piston end into the

barrel cylinder. Ensure that the piston loading o-ring

and seal ring are not damaged or dislodged.

19. Continue pushing the rod into the barrel until the cyl-

inder head gland can be inserted into the barrel cyl-

inder.

20. Secure the cylinder head gland using the washer

ring and socket head bolts. See Figure 5-1, Cylinder

Head and Tapered Bushing Torque Specifications

21. After the cylinder has been reassembled, the rod

should be pushed all the way in (fully retracted) prior

to the reinstallation of any holding valve or valves.

Figure 5-18. Tapered Bushing Installation

Figure 5-19. Seating the Tapered Bearing

Figure 5-20. Poly-Pak Piston Seal Installation

Figure 5-21. Rod Assembly Installation