Norgren VS18 Series Valve Advantage User Manual

Page 49

VS18/VS26

MAINTENANCE & INSTRUCTION BOOKLET

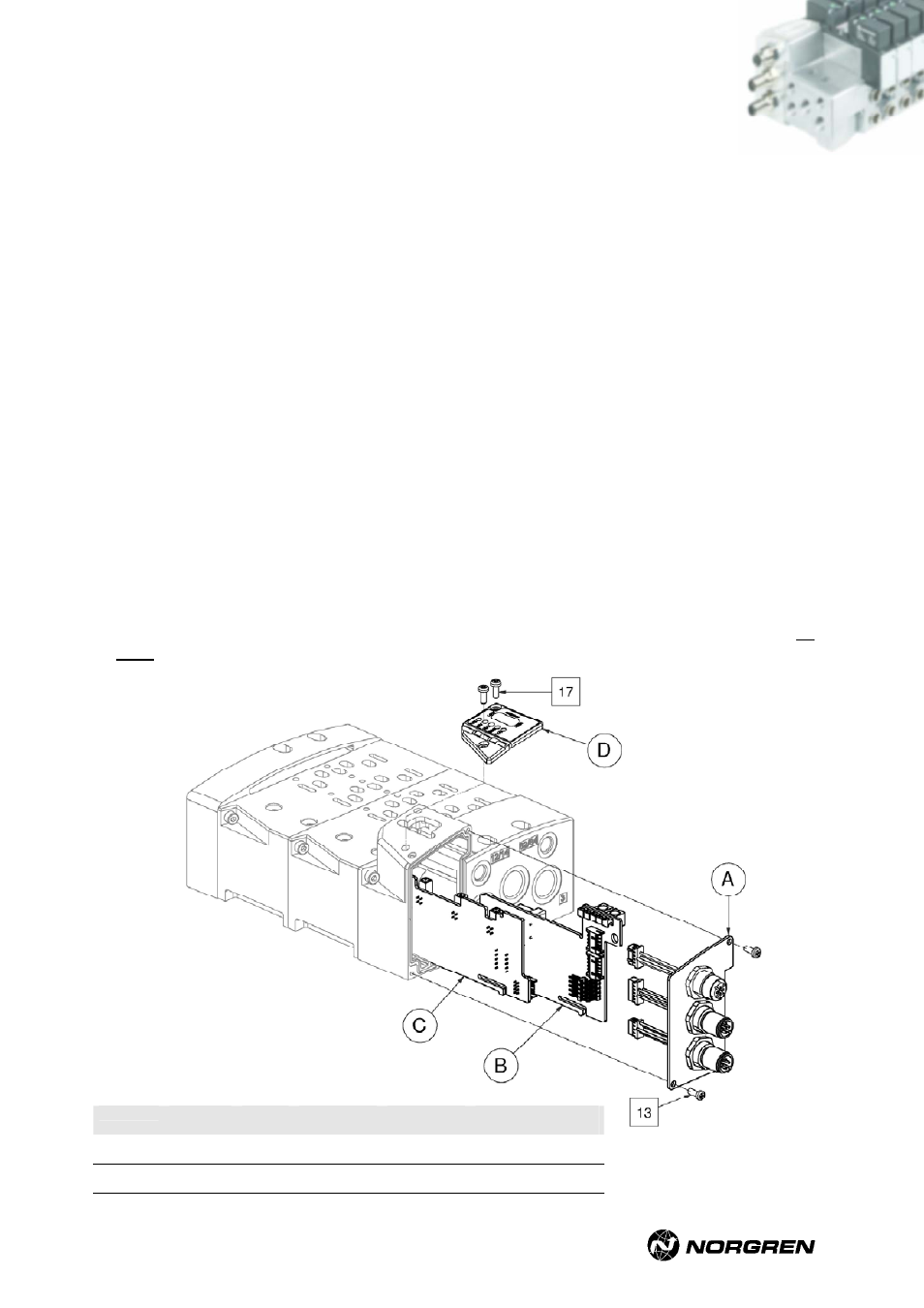

8.1.3 Fieldbus assembly / Installation of PCBs (excluding AS-Interface and FD67

bus)

Tool:

VS18/VS26

Philips screwdriver size 1

1. Important: Make sure valves are not already mounted on the valve island, because the

output PCB (C) could become damaged during assembly.

2. Insert first output PCB (C) in the left groove of the left end plate and the modular sub-bases.

Check to make sure the plug-in connection on the PCB is centred with the orifice to the

valve interface.

3. Insert Fieldbus PCB (B) in the right groove of the left end plate and the modular sub-bases.

4. Plug the lowest connector of the Fieldbus E-connector-kit (A) into the connector on the

output PCB (C).

5. Plug the remaining connector(s) of the Fieldbus E-connector-kit (A) into the connector(s) on

the Fieldbus PCB (B).

6. Ensure connector-kit gasket is fitted on the left end plate.

7. Mount the Fieldbus E-connector-kit (A) with two mounting screws on the left end plate.

Tighten the screws with the specified torque. If you are using a power screwdriver consider

the maximum speed allowed.

8. Ensure gasket on the bottom of the LED window (D) is fitted and place the LED window on

the left end plate. Turn mounting screws by hand in the existing threads and tighten then by

hand.

Screw

Type

(thread)

Valve

seize

Tightening

torque in Nm

Tightening

torque in Ibs

Max. screw driver

speed in r.p.m.

13 M3x8

VS18/

VS26

0.8 – 0.9

7.08 – 7.96

1100

17 M3x8

VS18/

VS26

0.4

3.54

Tighten by hand!

VS2672926-KG00E_05/07 Page

49/97