Appendix “a” - application example, Slow down & cut to length with total yardage – Red Lion C48C User Manual

Page 43

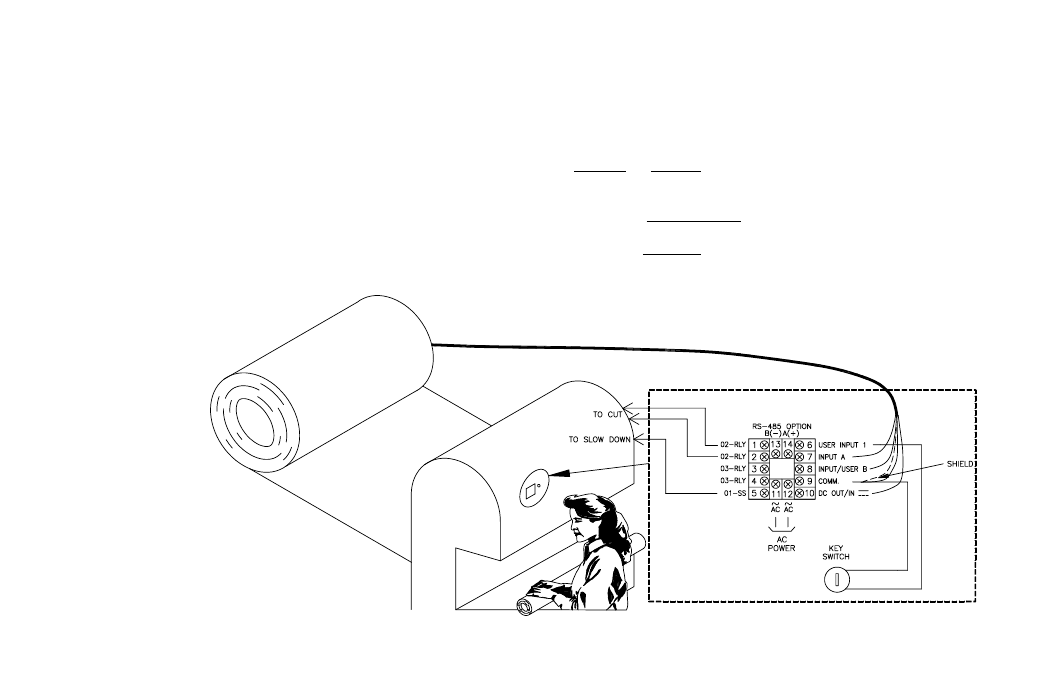

Slow Down & Cut to Length with Total Yardage

To improve production efficiency, a wallpaper manufacturing plant is

installing cut to length counters on the roll form machines. Currently, electro-

mechanical counters are used for length measurements. The operator slows the

machine down upon arriving at the desired length, stops and then cuts. The

addition of the C48CB batch counters eliminates the operator’s manual

observation and control.

The operator programs the required cut length as Preset 2. Preset 1 is

preprogrammed for tracking and will automatically follow Preset 2. Preset 1 is

used as the slow down, and is set for a value 0.25 yards less than Preset 2. The

process count is programmed to automatically reset at the Preset 2 cut length of

11.00 yards, and begin counting for the next roll. Counter 2 is programmed as a

totalizer and is recorded and reset (via key switch)

at the end of the operator’s shift. The C48CB

was ordered with the RS-485 serial

communication option. Future

plans

include

a

data

acquisition program to

interrogate

the

C48CB’s. A 100 ppr

rotary

pulse

generator is shaft

coupled to a 4” pinch

roller

for

length

measurement. Display

units desired is 0.01 yards.

Program Security features are set

to allow access to Preset 2 only. This

allows the operator to change the required

cut length, but prevents accidental changes to

other programming parameters that may adversely

affect process operation. After all programming is

complete, the Program Disable DIP switch is moved to the

up position to enable the Program Security function.

Circumference of pinch roller:

circumference =

π x diameter

12.56636 = 3.14159 x 4.00

Pulses per yard:

36 inches X 1 rev = 2.8647913 rev/yard

1 yard 12.56636

Prescaler:

Prescaler = Display Units

number of pulses

Prescaler = 100

286.47913

Prescaler = 0.34907

-37-

APPENDIX “A” - APPLICATION EXAMPLE