Summary of common printing problems, Asummary of common printing problems – HP Latex 360 Printer User Manual

Page 176

A

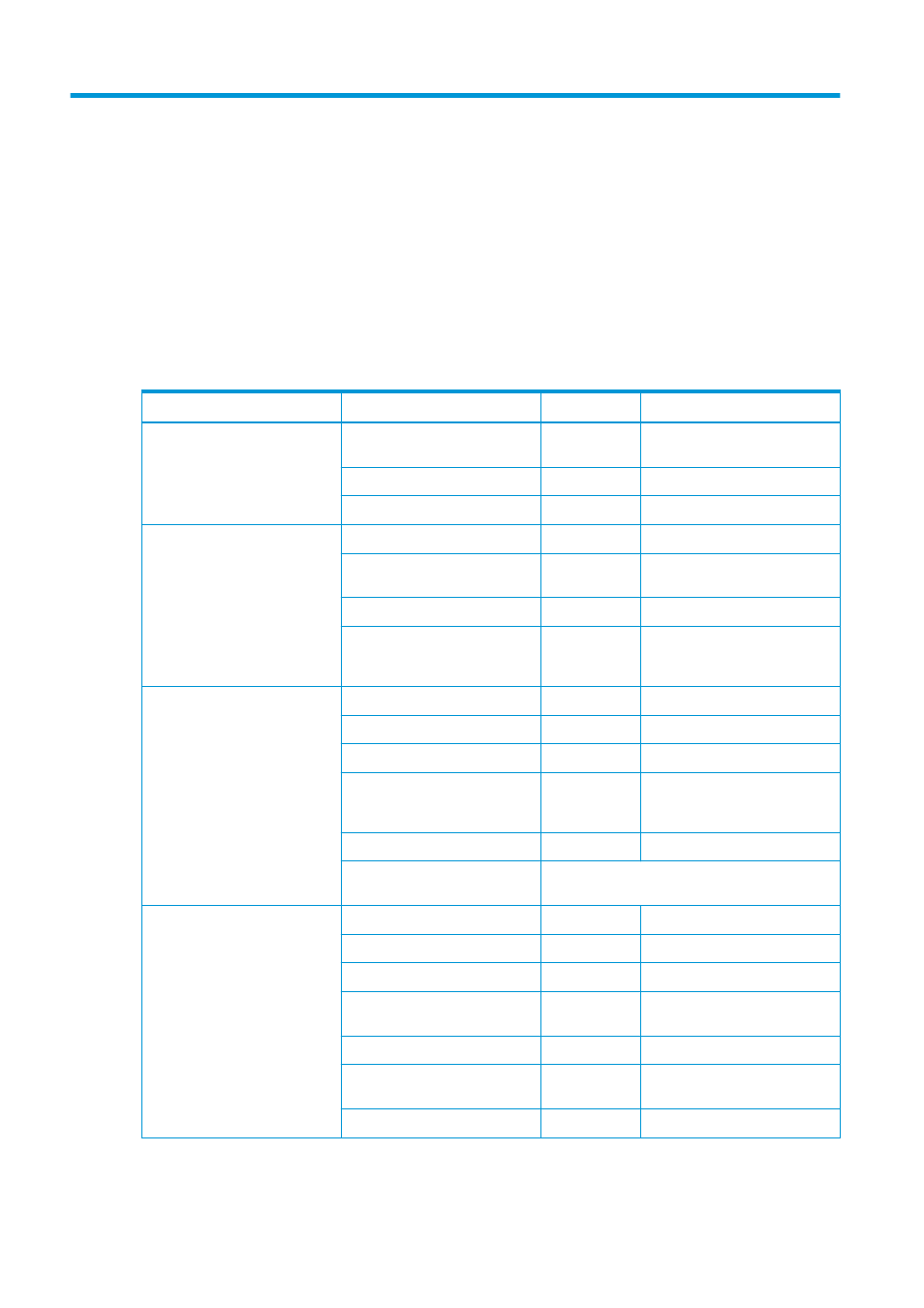

Summary of common printing problems

This is a table of common problems and the parameters that can be changed in order to solve the problem.

Some possible side-effects are also shown. For a more detailed treatment of any particular problem, please

see the relevant chapter in this guide.

Problem

Parameter

Change

Possible side-effects

Durability problems, ink smudges,

or oily finish

Curing temperature

Increase

Substrate jam, substrate damage,

ink smears

Number of passes

Increase

Slower printing

Inter-path delay offset

Increase

Slower printing

Substrate jam, substrate damage,

ink smears

Curing temperature

Decrease

Less durability (smudges), oily finish

Vacuum

Increase

Substrate skew, vertical banding if

increased too much

Top and/or bottom margins

Increase

Waste of substrate

Edge holders

Use

The minimum side margins increase

slightly, reducing the maximum

width of the printed image

Vertical banding in saturated area

fills

Ink limits

Decrease

Reduced color gamut

Inter-path delay offset

Increase

Slower printing

Number of passes

Increase

Slower printing

Cutter (360 only)

Disable

Manual substrate advance may be

needed to avoid crashes with some

substrates

Group jobs together

Yes

Avoids white space between prints

Modify the print queue

Avoid printing difficult jobs (using a lot of ink) at the

beginning of the queue

Horizontal banding in saturated

area fills

Ink limits

Decrease

Reduced color gamut

Inter-path delay offset

Increase

Slower printing

Number of passes

Increase

Slower printing

Modify color separations and dark

color generation

Align printheads

Clean substrate-advance sensor

(360 only)

Clean printheads

170 Appendix A Summary of common printing problems

ENWW