HP Latex 360 Printer User Manual

Page 105

2.

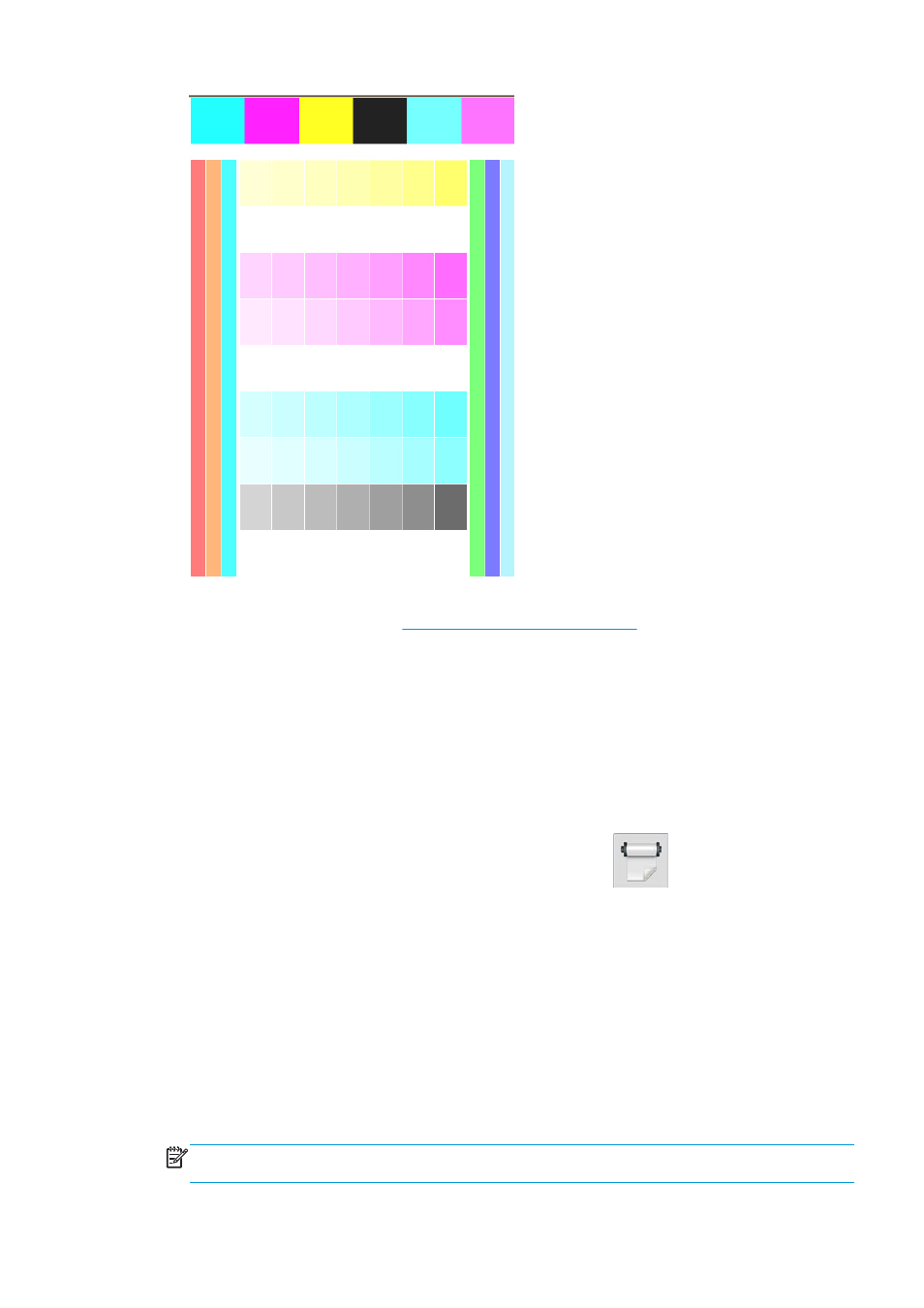

The test chart is scanned by the line sensor. If the scan cannot be completed successfully, a message is

displayed on the front panel; see

Front-panel error codes on page 160

.

3.

From the measurements made by the line sensor, the printer calculates the necessary correction tables

to apply to your print jobs, for consistent color printing on that substrate type.

Calibration should be done in any of the following circumstances:

●

Whenever a new substrate type is introduced that has not yet been calibrated.

●

Whenever you notice excessive color differences between prints. Such color differences are mainly

caused by aging and wear of the printheads, installing new printheads, and changes in substrate

characteristics between one roll and another.

You can check the color calibration status of your substrate by pressing

on the front panel.

●

Recommended status indicates that this substrate has never been calibrated. In this case, the factory-

default color tables will be applied to print jobs, as there is no reference state defined. After one or

more color calibrations have been performed, pressing the Reset button returns the status to

Recommended.

●

Done status indicates that a color calibration has been performed successfully at least once on this

substrate, and therefore a color reference state is defined.

●

Obsolete status indicates that the last color calibration may be out of date. For instance, color

calibration status is set to Obsolete whenever a printhead is replaced. The color reference state remains

defined.

●

N/A indicates that this substrate cannot be color-calibrated.

NOTE:

Generic substrates cannot be color-calibrated, although such substrates may be suitable for

color calibration. You can color-calibrate clones of most generic substrates.

ENWW

Color calibration

99