Block diagram, Operation, Block diagram 13 operation 13 – Badger Meter SRD/SRI Valve Positioners User Manual

Page 13

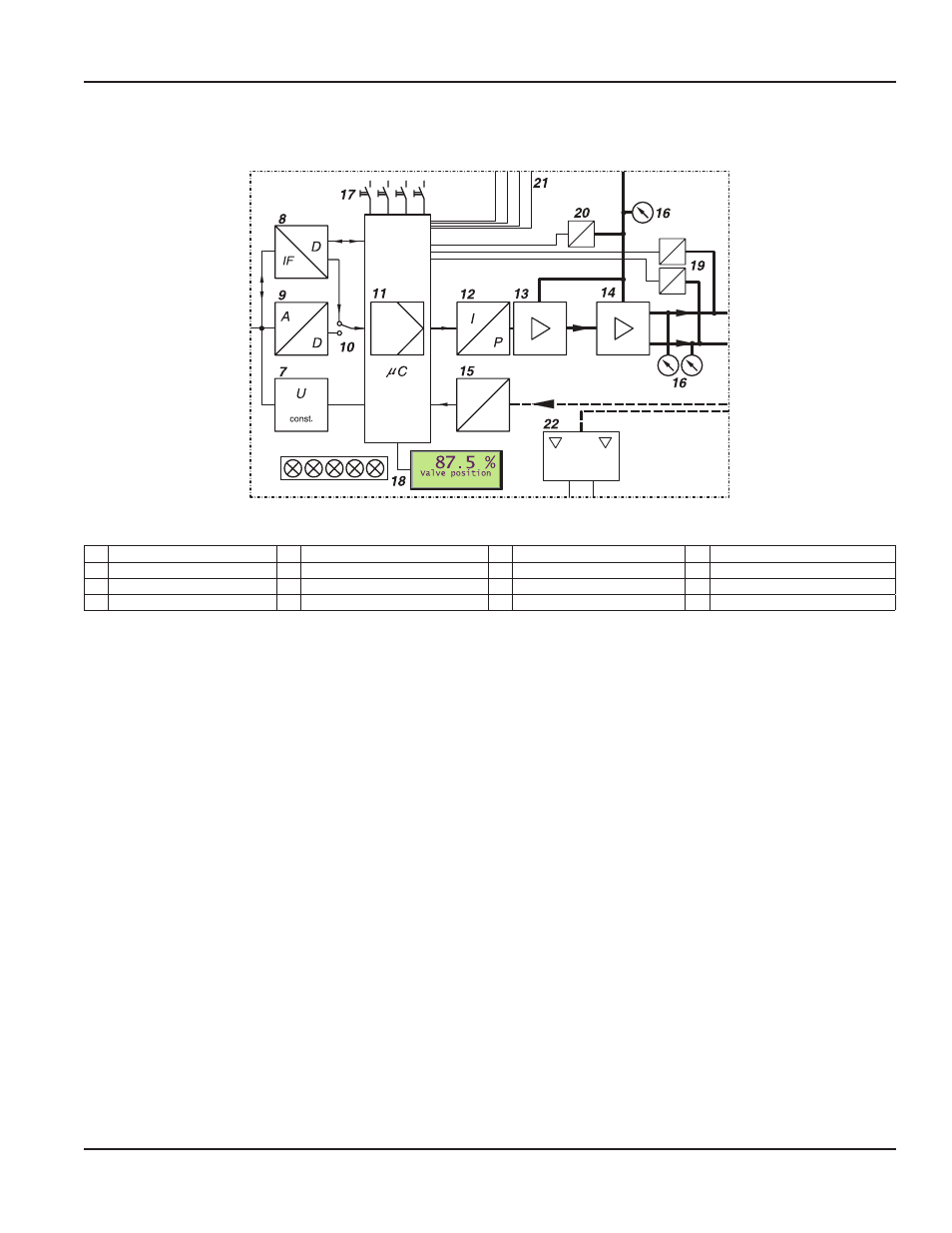

Block Diagram

x

Position

of actuator

y

1

Output

pressure

y

2

to actuator

Input (w) each

acc. to version:

•

Analog operation

4...20 mA

(+FSK)

•

Digital operation

FSK

13...36 V DC

•

Bus input

s Air supply 1.4 ... 6 bar (20 ... 90 psig)

Figure 7: Block diagram

7 Voltage Converter

11 Digital Controller

15 Position Sensor

19 Pressure Sensor

8 Interface Component

12 IP Module

16 Optional Gauges

20 Pressure Sensor

9 A/D Transformer

13 Pre-Amplifier

17 Local Keys

21 Outputs

10 Switch

14 Pneumatic Power Amplifier

18 LCDs

22 Optional Mechanical Limit Switch

Operation

With the universal positioner with input signal 4…20 mA or superimposed HART signal, the supply takes place via the power

signal adjacent to the input

By means of voltage converter 7, derivation of the internal supply of the electronic takes place The power value is measured,

in A/D transformer 9 converted, and directed via switch 10 to digital controller 11

With PROFIBUS-PA or FOUNDATION Fieldbus, the SRD is powered by means of the bus lead The positioner is operated

from a control system by sending a setpoint (setpoint value) to the positioner The digital signal is directed via the interface

component 8 to the digital controller 11 By means of the voltage converter 7 the internal supply of the electronic is

established, fed via the bus lead

With FoxCom digital operation, a DC voltage is provided at input w On this voltage a FSK-signal is modulated The modulation

contains information (such as setpoint value), sent digitally to the control unit 11 across the FSK-unit 8

The output of controller 11 drives the electro-pneumatic converter (IP-module) 12, controlling a pre-amplifier 13, the

single acting (or double acting) pneumatic power amplifier 14 The output of the amplifier 14 is the output pressure y to

the actuator

The pneumatic amplifiers are supplied with supply air s 1 4…6 bar (20…90 psig)

The position x of the actuator is sent to the control unit 11 by the position sensor (conductive plastic potentiometer) 15

Optional gauges 16, pressure sensors 19, 20, inputs / outputs 21 (two binary outputs; a 4…20 mA output and alarm;

control inputs for ‘Open/Close’ and ‘Hold last value’) enable additional diagnostic indications and possible intervention The

mechanical limit switch 22 (optional) enables independent alarm signals

Adjusting, startup of the positioner, and the demand for internal information can be made using the local keys 17 with

indication given by LCDs 18 or LEDs

Page 13

Method of Operation

August 2014

POS-UM-00009-EN-02