Precision air conditioning smartcool™ 6 - 200kw – Airedale SmartCool 11-233kW User Manual

Page 15

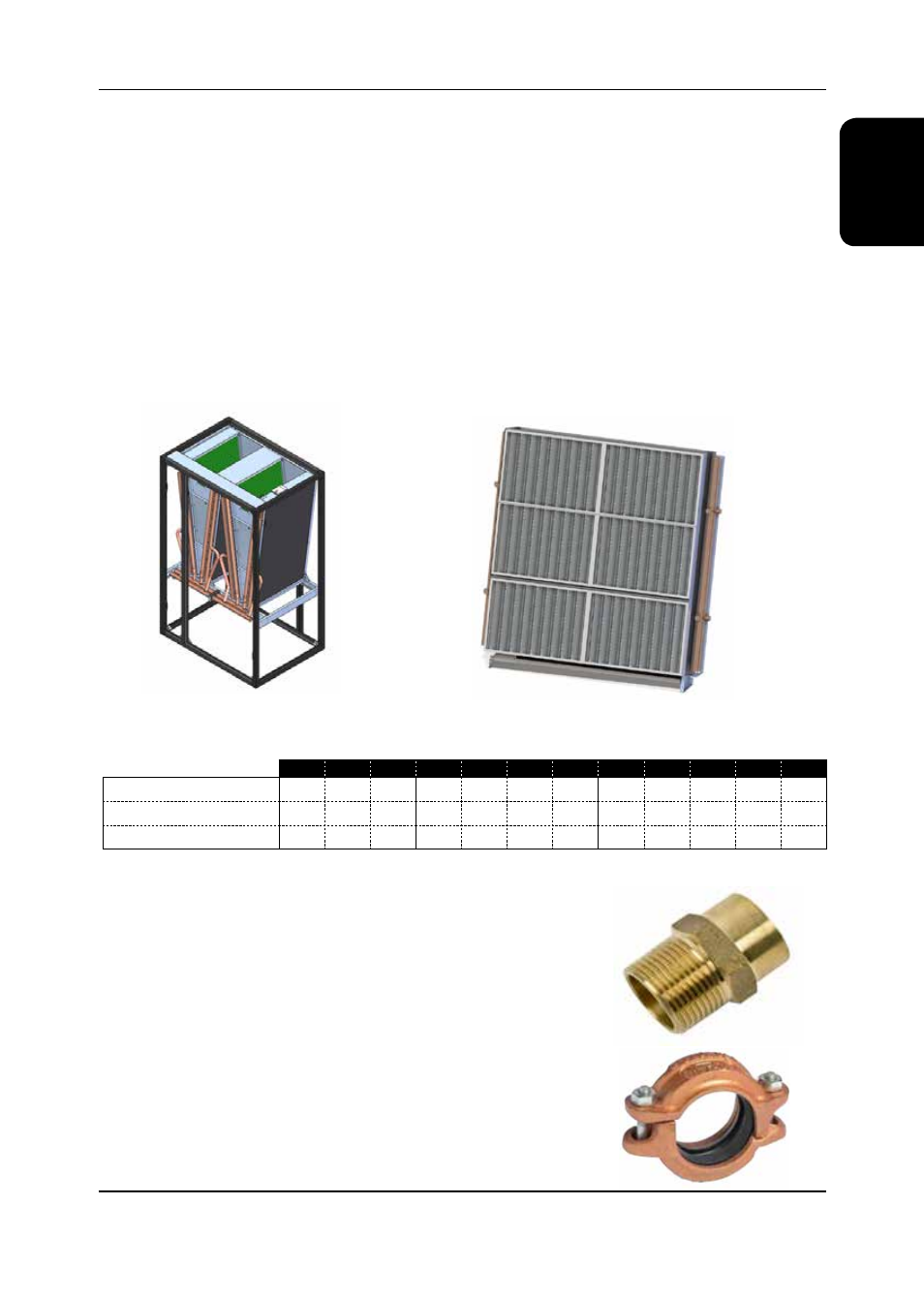

Chilled Water Coil

Chilled water coils shall be ideally positioned to optimise airflow and heat transfer, they shall be manufactured from plain

copper tubes with mechanically bonded aluminium fins. Fins shall be coated with a non-stick acrylic film (hydrophilic) to

provide additional corrosion protection and efficient surface water removal for improved performance. Plain aluminium

shall not be acceptable.

The cooling coil shall be mounted over a full width stainless steel condensate tray.

For control of water flow, various valve options shall be fitted.

The factory test pressure shall not be less than 20 Barg and the maximum operating pressure shall be less than 10.

Sweat copper pipe for brazed connection shall be standard. Optional threaded and Grooved connections shall be

available.

Grooved Water Connections

Grooved water connections shall be avaliable enabling easy

pipework termination.

Threaded Water Pipe Connection

As an alternative to brazed water pipe connections, BSP

brass male taper threaded connections shall be factory fitted.

SN06 SN09 SN12 SR09 SR12 SR15 SR18 SD18 SD22 SD25 SD31 SD35

Sweat Copper Connection

●

●

●

●

●

●

●

●

●

●

●

●

Threaded Pipe Connection

○

○

○

○

○

○

○

○

○

○

○

○

Grooved Water Connection

–

–

–

–

–

–

–

○

○

○

○

○

●

Standard Features

○

Optional Features

–

Feature Not Available

SN, SR Coils

SD Coil

Precision Air Conditioning

SmartCool™ 6 - 200kW

15

SmartCool 6 - 200kW Chilled Water Technical Manual 7674716 V1.1.0_04_2014

Introduction