Technical data – KROHNE OPTIBAR PC 5060 C EN User Manual

Page 62

7

TECHNICAL DATA

62

OPTIBAR PC 5060 C

www.krohne.com

04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

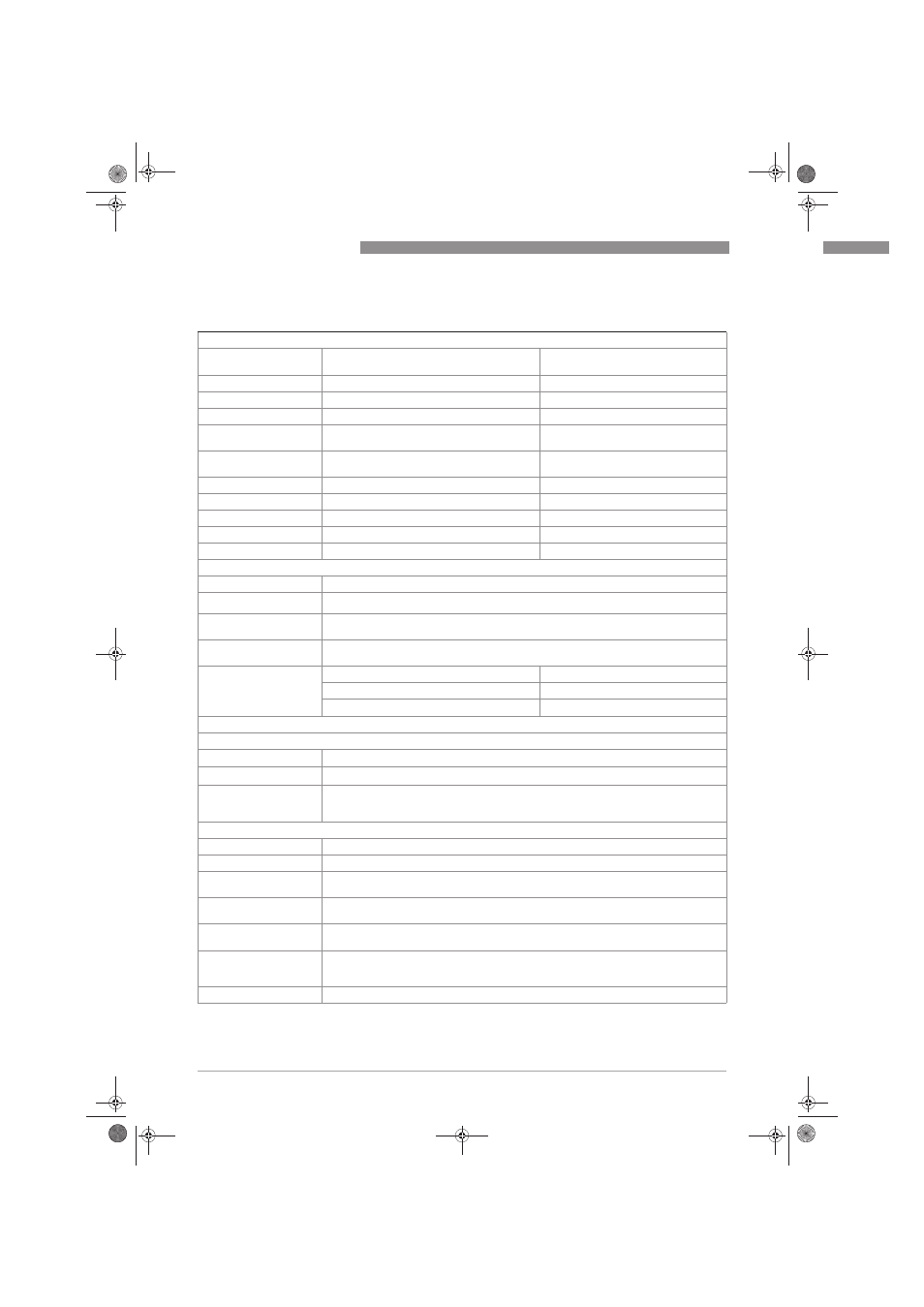

Materials

Gaskets

Gaskets

Gaskets

Gaskets

Standard version

Version with extended temperature

range

FKM (VP2/A)

-20...+130°C / -4...+266°F

-20...+150°C / -4...+302°F

FKM (A+P 70.16)

-40...+130°C / -4...+266°F

-

FKM (ET 7056)

-20...+130°C / -4...+266°F

-

EPDM (A+P 75.5/KW75F)

-40...+130°C / -40...+266°F

1h: +140°C / +284°F cleaning temperature

-40...+150°C / -40...+302°F

EPDM (ET 7056)

-40...+130°C / -40...+266°F

1h: +140°C / +284°F cleaning temperature

-

FFKM (Kalrez 6375)

-20...+130°C / -4...+266°F

-20...+150°C / -4...+302°F

FFKM (Perlast G75S)

-15...+130°C / +5...+266°F

-15...+150°C / +5...+302°F

FFKM (Perlast G75B)

-15...+130°C / +5...+266°F

-15...+150°C / +5...+302°F

FFKM (Chemraz 535)

-30...+130°C / -22...+266°F

-

FEPM (Fluoraz SD890)

-5...+130°C / +23...+266°F

-

Wetted parts

Wetted parts

Wetted parts

Wetted parts

Process connection

316 L / 1.4404, PVDF, Alloy C-22, Alloy C-276, Duplex 1.4462 and Titan Grade 2.

Diaphragm

Sapphire ceramic

®

(>99.9% AL

2

O

3

ceramic)

Joining material

diaphragm/base body

Glass (non-wetted for double seal and moulded seal)

Measuring cell seal

FKM (VP2/A, A+P 70.16), EPDM (A+P 75.5/KW75F), FFKM (Kalrez 6375, Perlast G75S,

Perlast G75B)

Gasket for process

connection (included)

Thread G1/2 (EN 837)

Aramid fibres, bound with NBR

Thread G1 1/2 (DIN 3852-A)

Aramid fibres, bound with NBR

M44 x 1.25 (DIN 13), M30 x 1.5

FKM, FFKM and EPDM

Materials for food applications

Materials for food applications

Materials for food applications

Materials for food applications

Surface quality hygienic connections

316 L process connection

R

a

< 0.8 µm

Ceramic diaphragm

R

a

< 0.7 µm

Gasket under wall mount

plate 316 L with 3A

approval

EPDM

Non-wetted parts

Non-wetted parts

Non-wetted parts

Non-wetted parts

Electronics housing

Plastic PBT (Polyester), powder coated die-cast aluminium, 316 L / 1.4404

External housing

Plastic PBT (polyester) and 316 L / 1.4404

Base, wall mount external

housing

Plastic PBT (polyester) and 316 L / 1.4404

Gasket between base and

wall mount

EPDM (permanently attached)

Housing cover sealing

ring

Silicone (aluminium or plastic housing), NBR (stainless steel housing)

Inspection window in

housing cover (display,

adjustment module)

Polycarbonate (UL746-C listed)

Ground terminal

316 Ti, 316 L / 1.440

.book Page 62 Friday, May 2, 2014 12:49 PM