Start-up – KROHNE OPTIBAR PC 5060 C EN User Manual

Page 44

5

START-UP

44

OPTIBAR PC 5060 C

www.krohne.com

04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

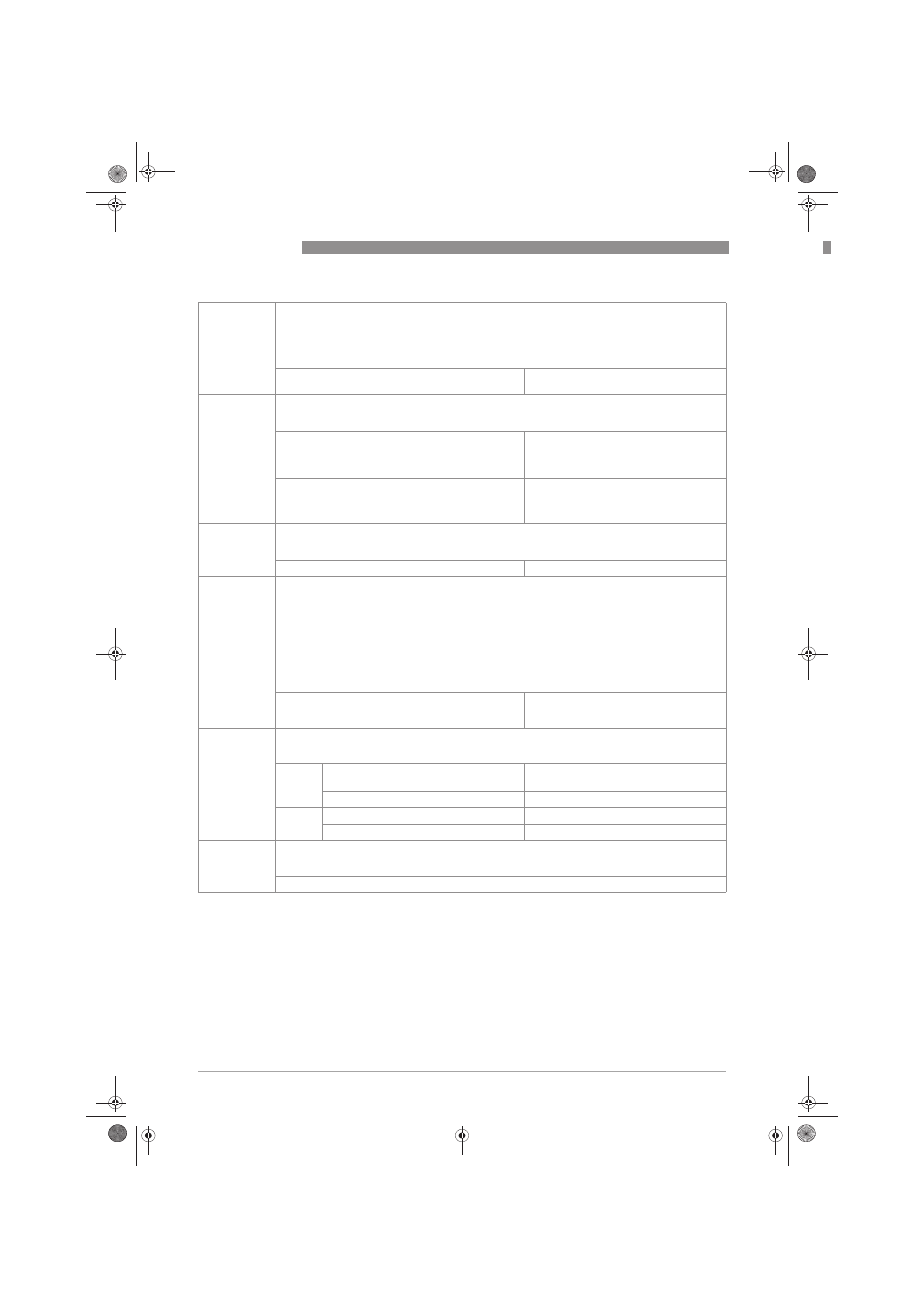

Sensor

mounting

correction

The mounting position of the device has a great impact on the measured value (offset), especially with

small measuring ranges and isolating systems. The position correction compensates for this offset.

The position correction can automatically take on the current measured value as correction value

(auto correct). Alternatively, this correction value can also be entered manually using the "Edit"

function. Once the position has been corrected, the measured value is corrected to 0. Position

correction can compensate for a maximum of 20% of the nominal measuring range.

Offset

Input in adjustment unit, automatic transfer

of the current measured value

Adjustment

Adjustment refers to setting the zero point (zero) and maximum measured value (span). These values

correspond to the values of 4 and 20 mA. If the adjustment ranges are exceeded, the message

"Outside parameter limits" is displayed.

Min.-adjustment / Zero

Process pressure

Process pressure

Process pressure

Process pressure

Zero in %, pressure

Level (standard 0%)

Level (standard 0%)

Level (standard 0%)

Level (standard 0%)

Min. in X %, pressure or filling height

Max.-adjustment / Span

Process pressure

Process pressure

Process pressure

Process pressure

Span in %, pressure

Level (standard 100%)

Level (standard 100%)

Level (standard 100%)

Level (standard 100%)

Min. in X %, pressure or filling height

Damping

For the damping of process-dependent measured value fluctuations, you can choose a suitable

integration time. The values which can be entered are from 0 … 999 seconds with an increment of 0.1

seconds.

Integration time

In 0.1 second increments

Linearization

A linearization is necessary for all vessels in which the vessel volume does not increase linearly with

the level, e.g. in a horizontal cylindrical or spherical tank, and the indication or output of the volume is

required. Corresponding linearization curves are preprogrammed for these vessels. They represent

the correlation between the level percentage and vessel volume. By activating the appropriate curve,

the volume percentage of the vessel is displayed correctly. Enter the desired parameters using the

function buttons and save the entries. Note the following if the pressure transmitter with

corresponding approval is used as part of an overfill protection system according to WHG (Water

Resources Act): If a linearization curve is selected, the measuring signal is no longer linearly

proportional to the level. This must be taken into consideration by the user, particularly when setting

the switching point on the limit signal indicator.

Type of linearization

Level

Level

Level

Level

Linear, Horiz.cylinder, Sphere and User

programmable

Current output

In the current output menu, the saturation region for above or below a threshold is set. Under

"Current output min./max." these limit values can be set. The factory setting is 3.8 mA and 20.5 mA.

This corresponds to the NAMUR recommendation NE 43.

Mode

Output characteristic

0...100% = 4...20 mA or

0...100% = 20...4 mA

Failure mode

≤ 3.6 mA, ≥ 21 mA, last valid measured value

Min. and

Max.

Min. current

3.8 mA, 4 mA

Max. current

20.5 mA, 20 mA

Lock

adjustment /

Unlock

adjustment

In this menu item, a 4-digit PIN can be activated, which protects against undesirable or unintended

changes of the settings. With a PIN active, remote access via software or other systems is also no

longer possible.

Run now

.book Page 44 Friday, May 2, 2014 12:49 PM