Start-up, 9 adjustment – KROHNE OPTIBAR PC 5060 C EN User Manual

Page 53

START-UP

5

53

OPTIBAR PC 5060 C

www.krohne.com

04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

5.8.5 Software update

The following components are required for an update of the device software:

• Sensor

• Power supply

• USB interface adapter

• PC with PACTware

TM

• Software update as file

The latest version of the device software can be found on the manufacturer website. Further

information is provided in the software update file.

Certain approvals can be subject to a specific software version. Therefore, when carrying out an

update, ensure the approval is retained.

5.9 Adjustment

The pressure transmitter always measures a pressure, regardless of the process variable

selected in the menu item "application". To properly output the selected process variable, there

must be an allocation of 0 % and 100 % of the output signal (adjustment). In the case of the

"level" application the hydrostatic pressure when the vessel is full and empty, for example, could

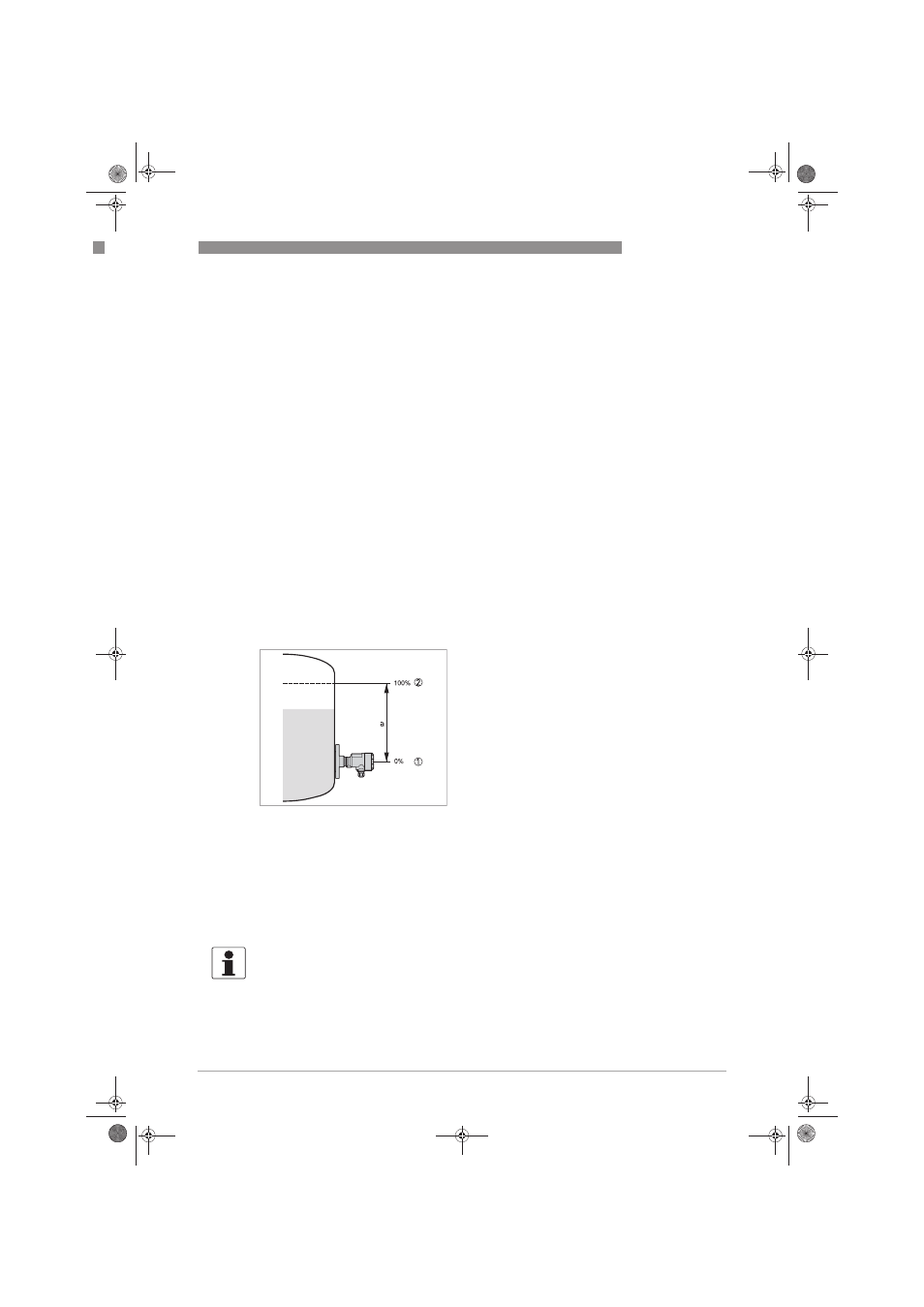

be entered for adjustment. See the following example:

If these values are not known, adjustments can be made with levels of 10 % and 90 % for

example. Using these inputs, the actual filling height is then calculated. The current level plays

no role in this adjustment, the min/max adjustment is always carried out without changing the

product. This means that these settings can be made in advance and the device does not need to

be installed.

Figure 5-1: Level measurement (a = 5 m / 196,9")

Min. level 0% corresponds to 0.0 mbar / psi

Max. level 100% corresponds to 490.50 mbar / 7.11psi

INFORMATION!

If the adjustment ranges are exceeded, the value entered is not saved. Editing can be cancelled

with [ESC] or corrected to a value within the adjustment range. Adjustment is carried out

accordingly for the remaining process variables such as process pressure, differential pressure

and flow.

.book Page 53 Friday, May 2, 2014 12:49 PM