Technical data – KROHNE OPTIFLEX 1100C EN User Manual

Page 62

8

TECHNICAL DATA

62

OPTIFLEX 1100 C

www.krohne.com

01/2012 - 4001721801 - HB OPTIFLEX 1100 R01 en

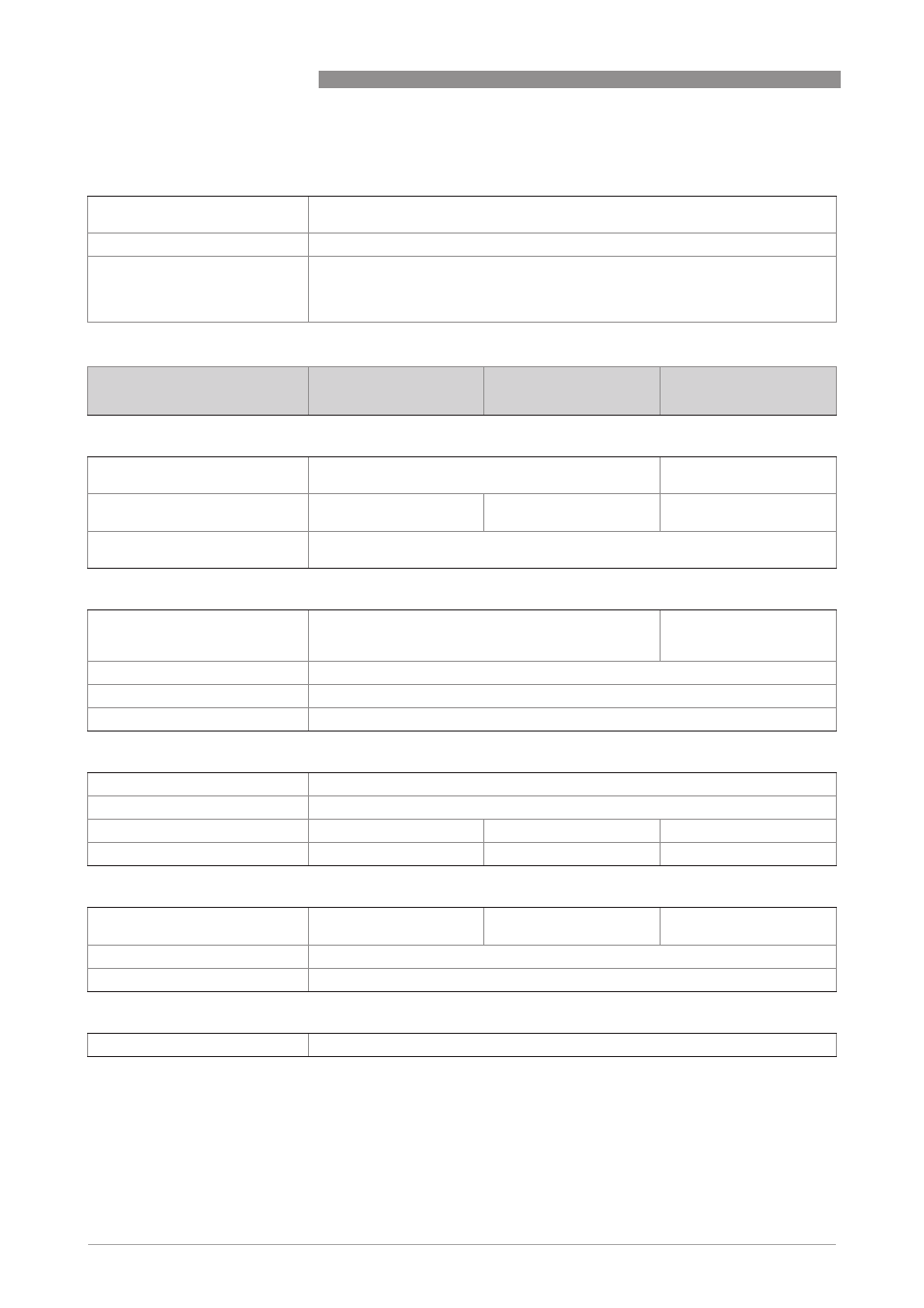

Probe options

Approvals and certification

CE

This device fulfils the statutory requirements of the EC directives. The

manufacturer certifies successful testing of the product by applying the CE mark.

Vibration resistance

EN 60068-2-27, -29, -34

EMC

Electromagnetic Compatibility Directive 2004/108/EC in conjunction with

EN 61326-1 (2006). The device agrees with this standard if:

- the device has a coaxial probe or

- the device has a single probe that is installed in a metallic tank.

Segmented coaxial

Ø14 mm / 0.55¨

Single cable

Ø2 mm / 0.08¨

Single cable

Ø4 mm / 0.15¨

Measuring system

Application

Level measurement of liquids

Level measurement of

solids

Measuring range

0.73...4.067 m /

2.4...13.3 ft

1

1...20 m /

3.3...65.6 ft

1...10 m /

3.3...32.8 ft

Dead zone

This depends on the type of probe. For more data, refer to

Measurement limits

on

page 64.

Measuring accuracy

Accuracy

±

10 mm / ±0.4¨, when distance ≤ 10 m / 33 ft;

±

0.1% of measured distance, when distance

> 10 m / 33 ft

±

20 mm / ±0.8¨

Resolution

1 mm / 0.04¨

Repeatability

±

2 mm / ±0.08¨

Maximum rate of change at 4 mA

10 m/min / 32.8 ft/min

Operating conditions

Temperature

-50…+100°C / -60…+212°F

Pressure

-1…16 barg / -14.5…232 psig

Viscosity

≤500 mPa.s

10000 mPa.s

n/a

Dielectric constant

≥ 1.6

≥ 2.1

≥ 2.1

Materials

Probe

Stainless steel

(1.4404 / 316L)

Stainless steel

(1.4401 / 316)

Stainless steel

(1.4401 / 316)

Gasket (process seal)

EPDM

Process connection

Stainless steel (1.4404 / 316L)

Process connections

Thread

G ¾…1A; ¾…1 NPT

1 The coaxial probe can be supplied in 6 standard lengths: 730 mm / 29¨, 1397 mm / 55¨, 2065 mm / 81¨, 2732 mm / 108¨, 3400 mm / 134¨

or 4067 mm / 160¨. If necessary, shorten the probe. For more data, refer to the Installation chapter.