A/d converter, Pen servo (pen model), Plotter (pen model) – Yokogawa µR20000 User Manual

Page 9: Printing mechanism (dot model)

1-2

SM 04P02B01-01E

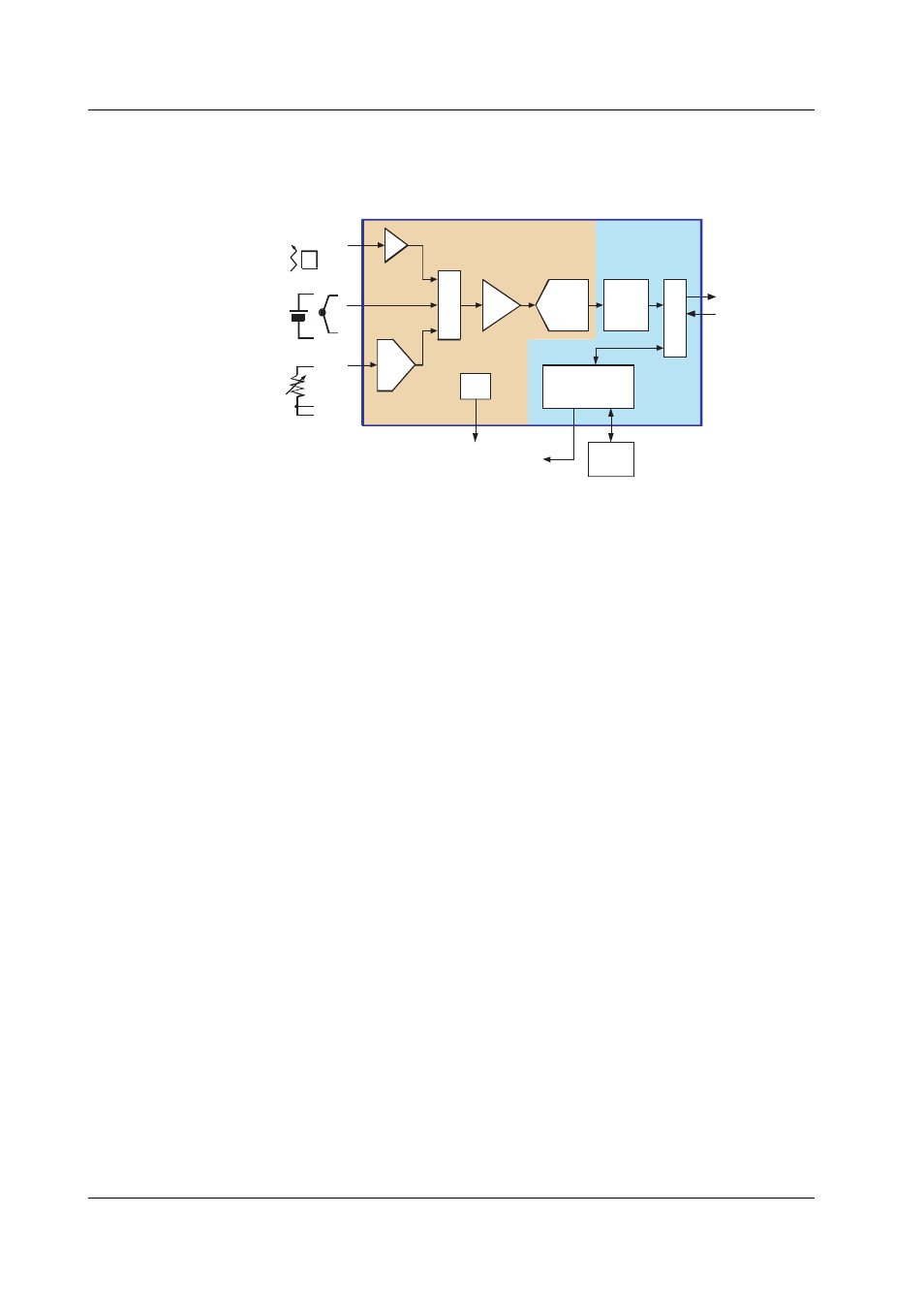

A/D Converter

ASIC

Uses a proprietary one-chip ASIC. The ASIC is a combination analog/digital IC that

contains popular CMOS processes. The table below shows its configuration.

RJC Amp

RTD Amp

Multiplexer

PGA

A/D

Digital

Filter

UART

Controller

Vref

EEPROM

Scanner

Control

BiCMOS Analog

CMOS Digital

Temperature

Sensor

Volt, TC

RTD

• Controller

Controls switching of the input signal by the scanner, and switching of the A/D

converter attenuator and RTD/TC mode.

• PGA (programmable gain amplifier)

Programmable amplifier with a gain of 1 to 100 times.

• A/D

Converts analog signals to digital signals. Uses a pulse width modulation-based

integrating A/D converter that suppresses the effects of noise on the input signal. With

dot models, data is converted from the 6 channel per second model and the 12 to 24

channels per 2.5 seconds model.

• UART (Universal Asynchronous Receiver-Transmitter)

Performs serial communications with the CPU via a photocoupler.

EEPROM

Stores data modified by the A/D converter.

Pen Servo (Pen Model)

Balances the pen in the recording position.

• Uses a compact, lightweight motor with a photoencoder.

• The motor is attached to the pen carriage, and moves with the pen.

• The revolution of the motor is controlled by PWM signals from the CPU.

Plotter (Pen Model)

The pen model includes an XY plotter for printing. The plotter consists of an X-axis motor

positioned in the plotter assembly, the Y-axis motor installed in the carriage, and a

solenoid for moving the pen up and down.

Printing Mechanism (Dot Model)

Uses a field-proven six-color wire dot printing system. Also, follows a raster scan

method

*

that helps maintain the life-span of the drive train wire. It consists of a driver

board, carriage motor, ribbon shift motor, and other components.

*

The printing carriage moves in alternation from left to right and right to left every recording

interval, and prints measured values. When the printing carriage moves from left to right,

measured values are printed in the appropriate order starting on the left. When the printing

carriage moves from right to left, measured values are printed in the appropriate order

starting on the right.

1.1 Principles of Operation