Getting started, 1 connection of devices, Getting started -1 – Yokogawa AXFA14G/C User Manual

Page 8: Connection of devices -1

IM 01E20F12-01E

3-1

3. GETTING STARTED

3.

GETTING STARTED

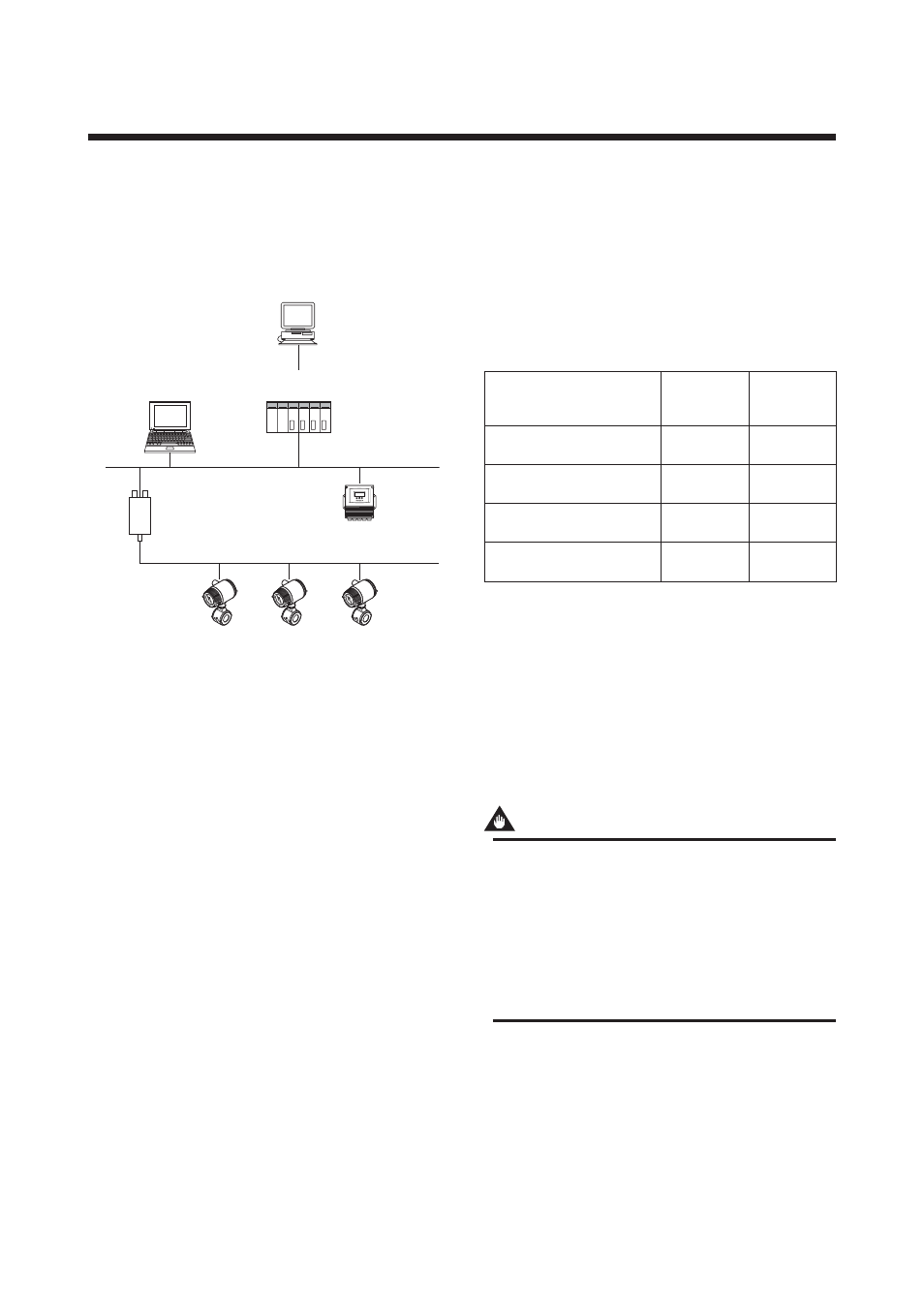

Fieldbus is fully dependent upon digital communica-

tion protocol and differs in operation from conven-

tional 4 to 20 mA transmission and the BRAIN

communication protocol.

HMI

Class I Master

I/O CARD, PLC, etc.

PROFIBUS-DP

PROFIBUS-DP devices

PROFIBUS-PA devices (AXF)

PROFIBUS-PA (31.25 kbps)

Class 2 Master

FieldMate (FDT/DTM)

PDM (EDDL), etc.

DP/PA

Coupler

F0301.EPS

Figure 3.1 Profibus System Construction

3.1 Connection of Devices

The following are required for use with PROFIBUS

PA devices:

• Power supply:

PROFIBUS PA requires a dedicated power supply.

It is recommended that current capacity be well over

the total value of the maximum current consumed

by all devices. Power is supplied by a DP/PA

coupler.

• Terminators:

PROFIBUS PA requires two terminators. A termina-

tor shall be located at each end of the trunk cable.

• Field devices:

Connect PROFIBUS PA communication type AXF

(Refer to section 8.3 terminal connection). Two or

more AXF devices or other devices can be con-

nected.

• DP/PA Couplers:

PROFIBUS PA requires DP/PA couplers which

convert the RS-485 signals to the IEC 61158-2

signal level and power the field devices via the

PROFIBUS PA.

• Cable:

Refer to Figure 3.1.

Table 3.1 PROFIBUS PA Cables and Transmissible Length

Type A: Individually-shielded

twisted pair cable

Type of cable

#18AWG

(0.82 mm

2

)

Cable

specifications

1,900 m

Max. length of

cable

(reference value)

1,200 m

400 m

200 m

#22AWG

(0.32 mm

2

)

#26AWG

(0.13 mm

2

)

#16AWG

(1.25 mm

2

)

Type B: Overall-shielded

twisted pair cable

Type C: Unshielded twisted

pair cable

Type D: Overall-shielded

non-twisted cable

T0401.EPS

Note: Yokogawa recommends the use of Type A.

Usage of Type B and D is restricted.

Yokogawa does not recommend the use of

Type C.

Before using a PROFIBUS PA configuration tool other

than the existing class 1 and class 2 Masters, confirm it

does not affect the loop functionality in which all

devices are already installed in operation. Disconnect

the relevant control loop from the bus if necessary.

IMPORTANT

• It is mandatory to turn on the power supply of

the AXF before turning on the power supply for

the Profibus line.

• Connecting a PROFIBUS PA configuration tool

to a loop with its existing class 1 and class 2

Masters may cause communication data

scrambling resulting in a functional disorder or

a system failure.