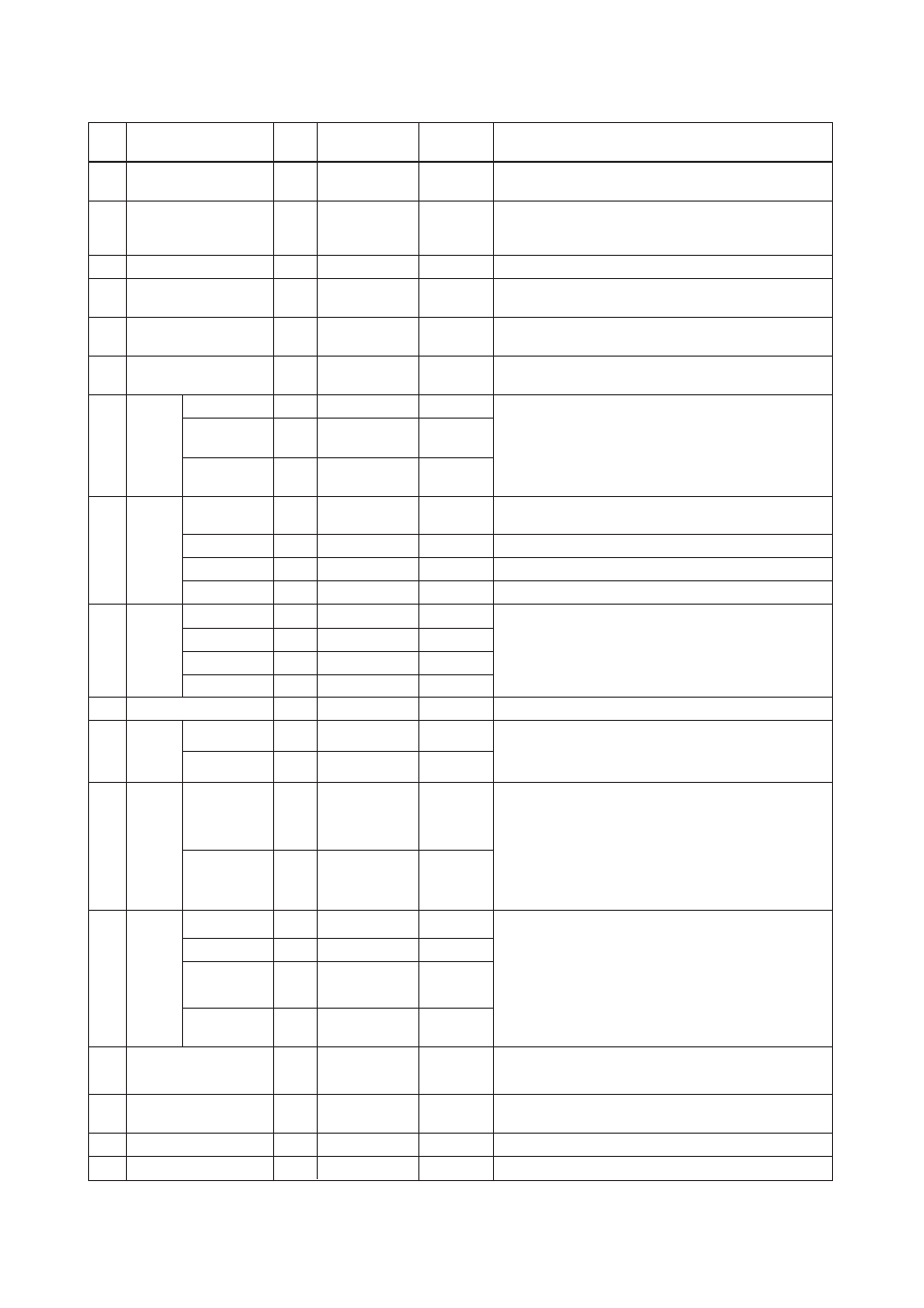

2 ai block parameter list (slot 1), Ai block parameter list (slot 1) -3 – Yokogawa AXFA14G/C User Manual

Page 61

IM 01E20F12-01E

9-3

9. PARAMETER LISTS

9.2

AI Block Parameter List (Slot 1)

T0902-1.EPS

Index

Parameter

Valid Range

Initial Value

Description

Write

Mode

Information on this block such as Block Tag, DD Revision, Execution

Time etc.

The revision level of the static data associated with the function block.

The revision value will be incremented each time a static parameter

value in the block is changed.

The user description of the intended application of the block.

The strategy field can be used to identify grouping of blocks.

This data is not checked or processed by the block.

The identification number of the plant unit. This information may be

used in the host for sorting alarms, etc.

16

–

BLOCK_OBJECT

17

–

0

ST_REV

18

Auto

TAG_DESC

19

Auto

0

0 to 65535

STRATEGY

20

Auto

0

0 to 255

ALERT_KEY

Set the Target of block mode (MODE_BLK) to Auto or O/S according

to the Write Mode of the parameter to be set or changed.

The mode parameter is a structured parameter composed of the

actual mode, the normal mode and the permitted mode.

Actual: Indicates the current operating condition.

Permit: Indicates the operating condition that the block is allowed

to take.

Normal: Indicates the operating condition that the block will usually

take.

21

22

Auto

Auto

–

Actual

MODE_

BLK

(DS-37)

Auto

The current alert status, unacknowledged status, unreported status

and disabled status of the alarms associated with the function block.

23

–

Current

ALARM_

SUM

(DS-42)

24

BATCH

(DS-67)

25

Not used

0

for future use

–

Unacknowledged

0

for future use

–

Unreported

0

for future use

–

Disabled

0

This parameter is intended to be used in Batch applications in line

with IEC 61512.

Auto

BATCH_ID

0

26

OUT

(DS-33)

This parameter contains the current measurement value from

Transducer Block or configuration adjusted engineering unit and the

belonging state in AUTO MODE.

OUT contains the value and status set by an operator in MAN MODE.

Man

Value

0

27

PV_

SCALE

Conversion of the Process Variable into percent using the high and

low scale values.

The engineering unit of PV_SCALE high and low scale values are

direct related to the PRIMARY_VALUE_UNIT of the configured

Transducer Block (configured via Channel parameter).

The PV_SCALE high and low scale values follow the changes of the

PRIMARY_VALUE_UNIT of the related Transducer Block

automatically, i.e. a change of the Transducer Block PRIMARY_

VALUE_Unit causes no bump at OUT from AI.

O/S

0.00001 to 32000

or

0

0.00001 to 32000

or

0

Array 1

O/S

1342: %, 1355:Ml/d

1522: Ml/h

1521: Ml/min , etc

Array 2

Specified at the

time of order

29

LIN_TYPE

This parameter is used in order to select the type of linearization.

O/S

0: no

linearisation

250: Not used

251: None

0

28

OUT_

SCALE

(DS-68)

Scale of the Process Variable.

This parameter contains the values of the lower limit and upper limit

effective range, the code number of the engineering unit of Process

Variable and the number of digits on the right hand side of the

decimal point.

O/S

EU at 100%

O/S

EU at 0%

O/S

Units Index

Auto exclude

0, 1, 2, 3

O/S

Decimal Point

Specified at the

time of order

Specified at the

time of order

Man

Status

0

0

0

4

Auto

RUP

0

Auto

OPERATION

0

Auto

PHASE

0

–

Permitted

O/S, Man,

Auto

The permitted bit is

only available.

O/S bit, Man bit,

Auto bit

–

Normal

Auto

Permitted bit is

only available.

Bit1, 2, 3, 4, and

7 are available.

TARGET_MODE

30

CHANNEL

Reference to the active Transducer Block which provides the

measurement value to the Function Block.

31

Not used

O/S

273

273

32

PV_FTIME

Time constant of a single exponential filter for the PV, in seconds.

Auto

more than 0sec

0.000