Cantoanalog, Canbus trigger, decode, and measure – Teledyne LeCroy CANbus TD and CANbus TDM - Operators Manual User Manual

Page 22

CANbus Trigger, Decode, and Measure

22

CANbus-TD-TDM-OM-E RevB

Setting Up CANbus Parameters using the Measure Setup option

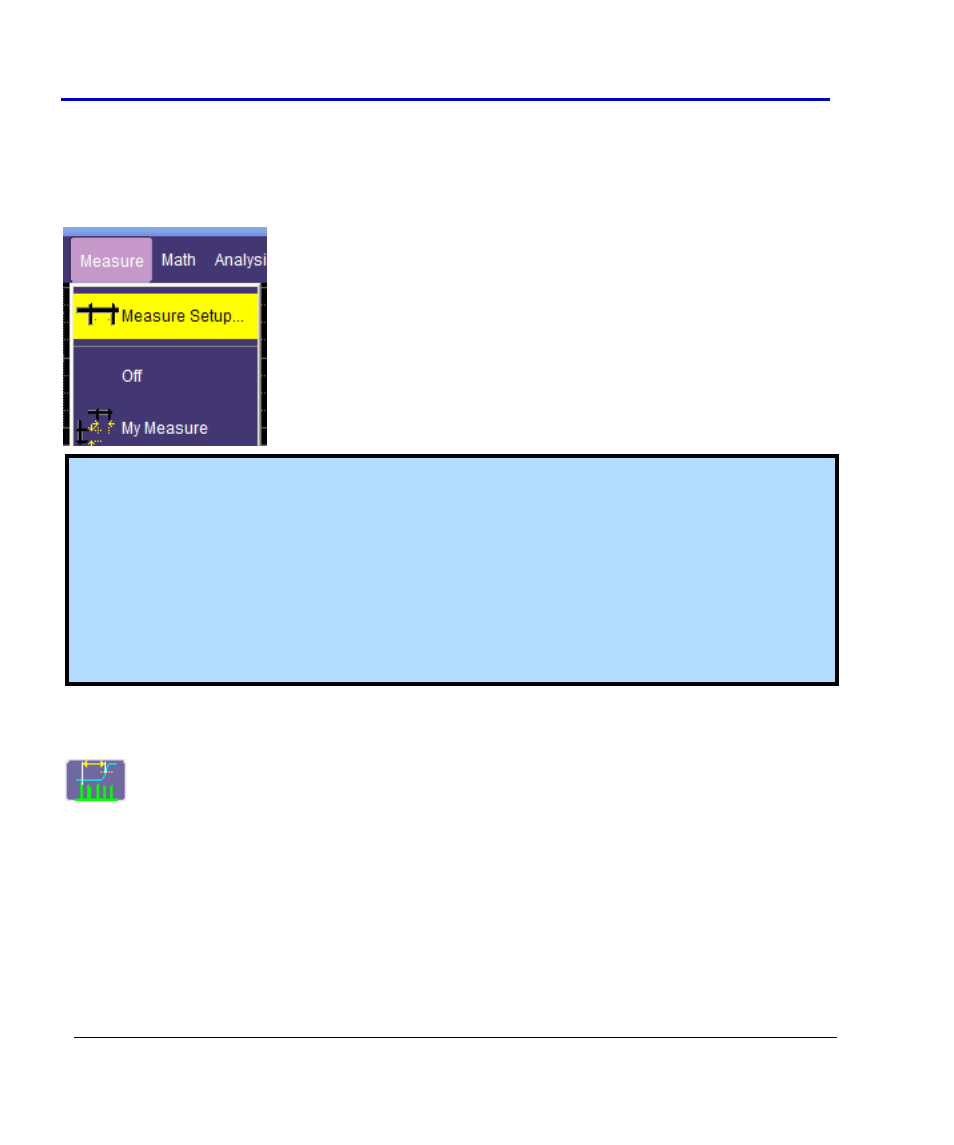

You can also set up measurement parameters using the Measure menu as follows:

Touch Measure→Measure Setup. select the appropriate CAN or other parameter. For more

information, see Parameter Setup in the oscilloscope's Online Help or Operator's Manual.

Note: All CAN measurement parameters (with the exception of CAN Load %) calculate as many

values as possible during each acquisition. If there are 10 timing events that meet the set

condition during a specific acquisition, 10 timing event measurements will be returned.

However, the VALUE shown in the measurement table is the last measurement made. To view

statistical data (i.e., number of measurements made, mean, min, max, std. dev.), turn Statistics

ON.

CAN Load % returns only one value during each acquisition, since it is evaluating the load % for

the entire acquisition time.

CAN-to-Analog or Analog-to-CAN Measurement Parameter

CAN Message to Analog Signal timing (CANtoAnalog)

This measurement parameter is used to measure timing from either a CAN Message to an

Analog Signal, or from an Analog Signal to a CAN Message. The Frame Type, ID, DATA, etc.

conditions for the CAN message can be fully defined, as can the slope, level, etc. conditions for

the analog signal transition.

If measuring from CAN to Analog, the timing is always measured from the End of Frame of CAN

message to the analog signal transition. If measuring from Analog to CAN, the timing is always

measured from the analog signal transition to the Start of Frame of the CAN message.