Preparation for calibration – Ronan X96S MASS FLOW GAUGE User Manual

Page 53

49

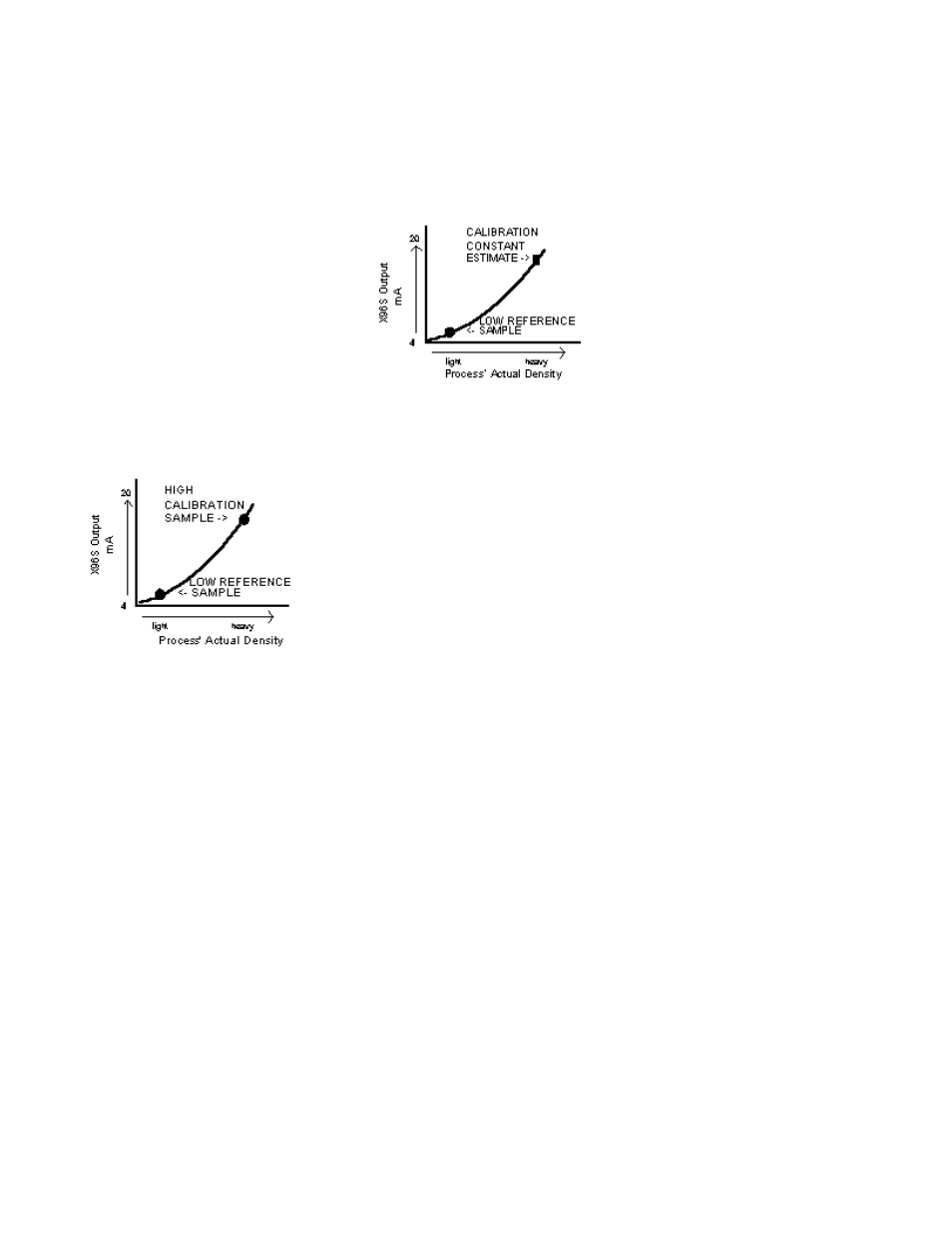

Calibration Curve

The first curve below shows the relationship for a single-point calibration between the Low Reference, the

Calibration constant, and the X96S output value.

The calibration curve below depicts a two-point calibration and the relationship between the Low

Reference, High Calibrate, and the X96S output value.

Preparation for Calibration

WHAT type of process sample is needed?

Any conveniently obtained process density that is within the range of interest can be used. For example,

water-based slurries could use water as the reference sample. Sub-water slurries could use an empty pipe

for the reference condition.

WHAT type of sampling procedure is needed?

The sampling procedure will depend upon your own process. You will have to do what is necessary to

obtain a truly representative sample of the density (ies) on which you are calibrating. Pull a minimum of

three samples of each density. (This means at least three samples of one density for single-point calibration,

and at least three samples of two densities for dual-point calibration). Take necessary precautions to

preserve the integrity of each sample.

WHAT type of laboratory analysis is required?

Precise laboratory analysis will produce the most accurate and useful results. If the results are temperature

compensated, you will need to enter the uncompensated values(s) into the X96S software.

Final gauge measurements can be only as accurate as your sampling and analysis technique and level

of accuracy.