Reference modes, Types of calibration – Ronan X96S MASS FLOW GAUGE User Manual

Page 52

48

Reference Modes

One of your first tasks will be to calibrate the system. The first step in the calibration procedure is to

"reference" the gauge on some known value. The steps involved in the referencing procedure will vary

slightly depending upon the mode selected in the “Ref Constants”.

One of these four REFERENCE MODES will be active on your system:

• Referencing EMPTY (SpG = 0)

• Referencing with WATER (SpG = 1)

• Referencing with PROCESS OF KNOWN DENSITY

• Referencing with ABSORBER

Most applications use the "Reference with Water" or the "Reference with Process" Mode.

Types of Calibration

Two types of Calibration are available for Ronan's Density Monitor.

Dual-Point Calibration requires an accurate laboratory analysis of truly representative samples of

two process densities. Dual-Point Calibration is preferred when the process can be varied to obtain

two process densities (one at each end of the measurement range).

Single-Point Calibration requires an accurate laboratory analysis of a truly representative sample of

one process density. Single-Point Calibration is used as an alternative method when it is not

physically or economically practical to vary the process density. In these cases, a second point is

estimated based on the mathematical formula for radiation transmission/absorption.

Calibration Constant

The two values, the reference density (d

o

) and the calibration constant (1/ut), are used by the X96S

algorithm to calculate process density (d).

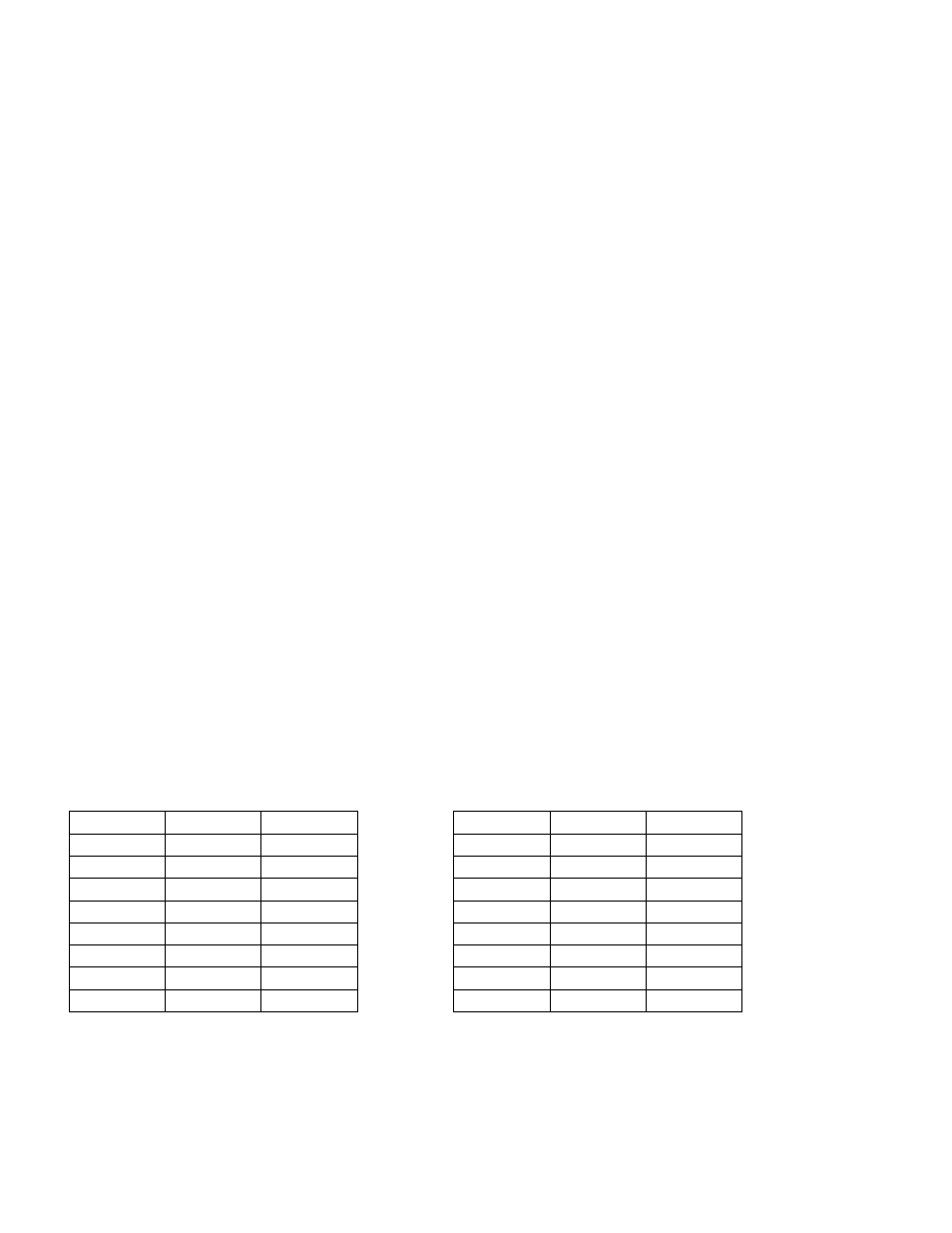

IF USING SA1:

IF USING RLL:

t

ut

1/ut

t

ut

1/ut

0.312

2”

0.4

2.5

2”

.32

2.083

3”

0.6

1.6

3”

.48

1.562

4”

0.8

1.25

4”

.64

1.25

5”

1.0

1.0

5”

.80

1.042

6”

1.2

0.825

6”

.96

0.781

8”

1.6

0.625

8”

1.28

0.625

10”

2.0

0.5

10”

1.6

t = mat'l thickness (pipe I.D.)

t = mat’l thickness (pipe I.D.)

u = absorption coefficient

u = absorption coefficient

= 0.2 for Cs137

= .16 for Cs137

1/ut = calibration constant

1/ut = calibration constant

Transmission/Absorption Table