Detector fault menu, Temp comp menu – Ronan X96S MASS FLOW GAUGE User Manual

Page 22

18

The Empty Clamp menu is used to configure the parameters associated with the mechanism that shuts off power to the detector if

the detector received more radiation than it is capable of measuring. It contains the following items:

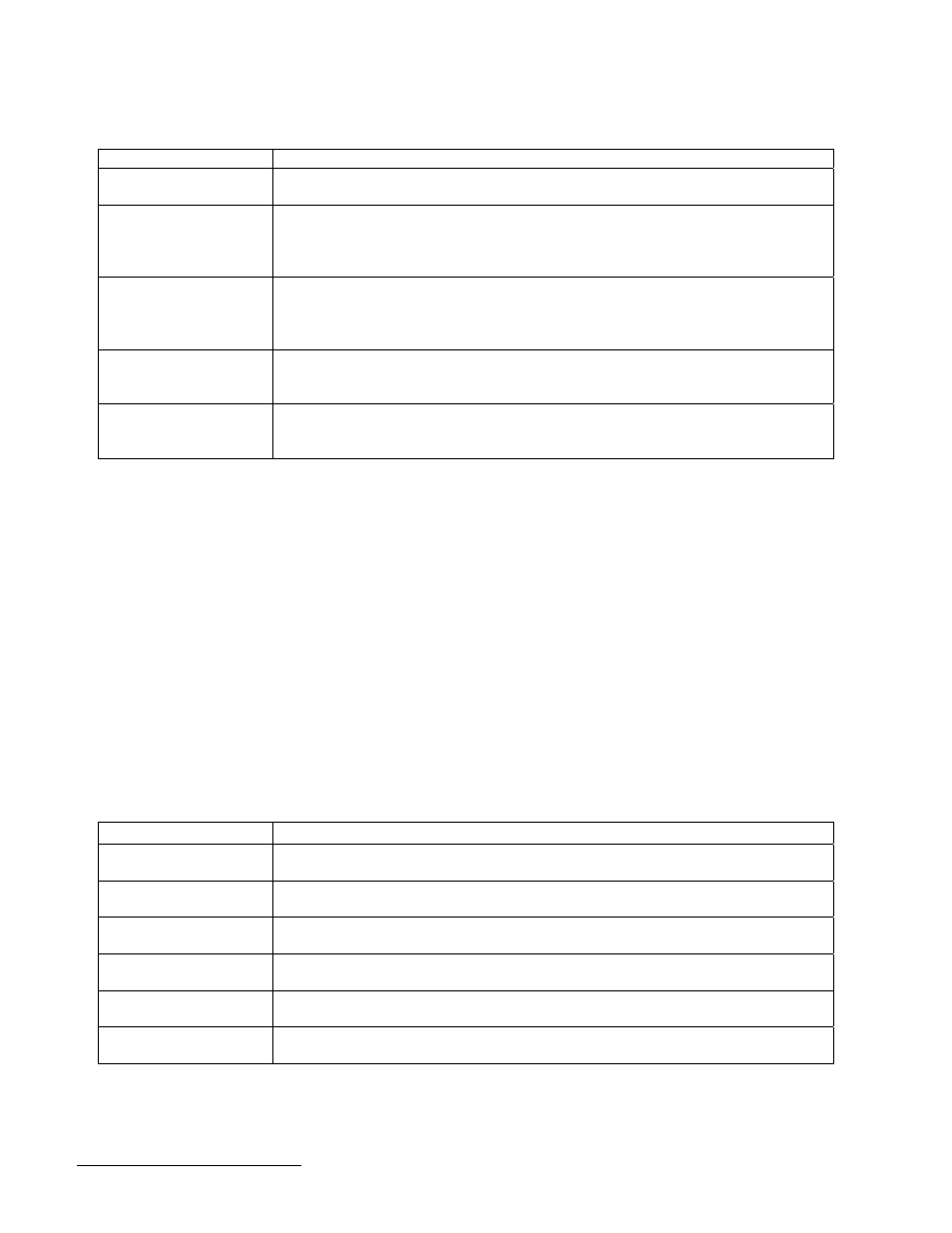

ITEM

FUNCTION

Empty Clamp

Shows the current state of the Empty Clamp mechanism (enabled or disabled) and

allows the user to change the state.

Off Time

Shows and allows the user to change the number of seconds that power to the detector

be shut off when the empty clamp mechanism activates before turning the detector on

to see if the radiation level has dropped to a value that the detector is capable of

measuring. Typical value ranges from 15 to 30 minutes.

Rcvry Time

Shows and allows the user to change the number of seconds that power will be applied

to the detector when the empty clamp mechanism has activated to see if the radiation

level has dropped to a value that the detector is capable of measuring. Typical value

here is 30 seconds.

Min Counts

Shows and allows the user to change the number-minimum number of counts that are

used to determine that the detector is saturated (exposed to more radiation than it is

capable of measuring).

Max Counts

Shows and allows the user to change the number maximum number of counts that are

used to determine that the detector is exposed to more radiation than it is capable of

measuring.

Detector Fault Menu

The Detector Fault menu is used to configure a window in which the detector counts must fall within, in order to complete a

reference/calibration.

Temp Comp Menu

Temperature compensation in the X96S is calculated as a quadratic function

3

. If temperature compensation is to be used, the

process temperature can be captured automatically for you during Referencing by enabling Temp auto Cap. If you choose to

enter the temperature manually, the entered value should be the temperature of the process material during the Referencing

function.

Process temperature is typically read via platinum or nickel, 2 or 3-wire RTD attached to the X96S. In these cases, the X96S

needs no temperature calibration. You can optionally feed a 0-10 Volt or 4-20mA signal into the X96S from another source that

represents the range of temperature for your process. In this case, you will need to perform a Temp Ref (in the Calibration Menu)

to set the range of measurement. You will also need to define the type of temperature device you are using in the Hardware Menu,

and Proc Temp menus.

The Temp Comp menu is used to control the temperature compensation mechanism. It contains the following items:

ITEM

FUNCTION

Temp Comp

Shows the current state of the Temp Comp mechanism (enable/disable) and allows the

user to change the state.

Temp Units

Shows and allows the user to set the temperature units used by the temperature

compensation mechanism.

A Coeff

Shows and allows the user to set the “A” coefficient that relates temperature to

changes in mass flow.

B Coeff

Shows and allows the user to set the “B” coefficient that relates to temperature to

changes in mass flow.

Enter Temp

Shows and allows the user to set the process temperature at the time that the gauge was

Referenced (if Auto Cap was ‘enabled’ during Referencing).

Temp Auto Cap

This invokes a method that captures the process temperature automatically during

gauge Referencing.

3

compensated density = uncompensated density + (A Coeff* temperature delta) + (B Coeff* temperature delta

2

)