Magnum Venus Plastech Megaject RTM Pro Revison 7_0 User Manual

Page 61

Megaject RTM Pro Manual – Revision 7.00 – 13

th

APRIL 2006

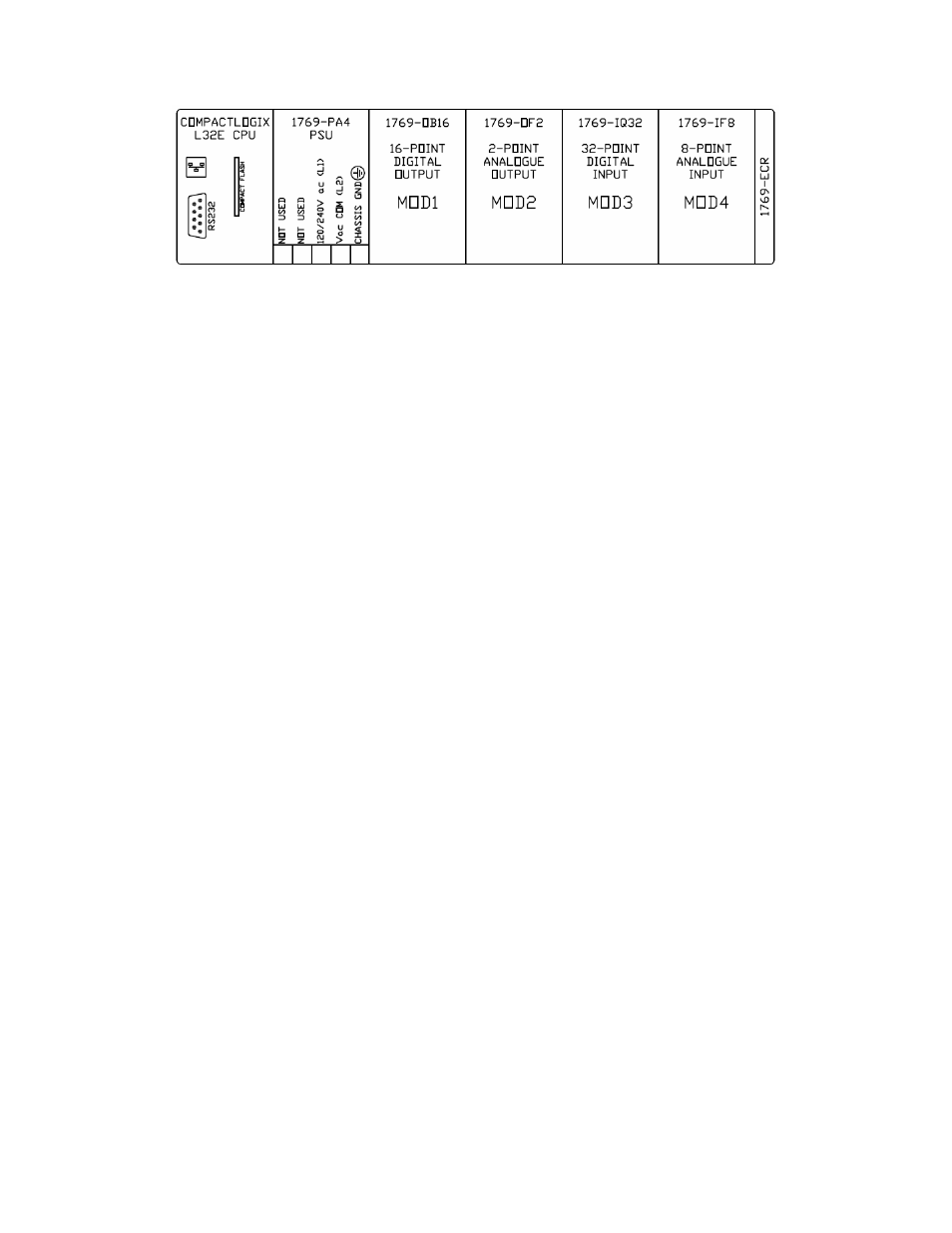

Figure 7.1 – Module configuration

Some of the inputs are alarmed and will cause the screen to display an error message

if a mal-function occurs.

7.2. Wiring Fault – Diagnosis Example

If a “Head valve position incorrect” alarm is generated, this immediately focuses the

fault to be either with the resin and/or catalyst valve being stuck in the wrong

position, or the valve’s associated sensor switch being out of position or the switch’s

wiring being faulty

As the machine mixing head is the main mobile part of the machine with several

sensors and moving parts, connection faults may occur in this zone more readily as

the head may be dropped or damaged against a mould.

In this example and any others concerning equipment and sensors associated with the

machine head, checks can be made on the signals at the white head terminal box.

A system check should follow the following steps:

1. Locate the machine equipment part/section being flagged as faulty and check its

correct mechanical function. In the case of the resin and/or catalyst valve example

check that the valve changes from recirculation position to injection position by

selecting IO check screen and operating the head valve test by touching the

appropriate button on the screen. If the valve is seen to operate through 90º correctly

proceed to the next stage. If not then service the valve.

2. Navigate to the IO check screen and ensure the digital inputs for the head valves are

correct for the position of the head valves. Check the signals change correctly when

the head vale is operated. If any of these conditions is not met then proceed to next

stage.

3. Check the limit switch sensors on the valves actuators are in position and held tight

with the locking screws. If any are found loose, or easily moved, then reposition until

the appropriate signal switches at the appropriate valve position. If these sensors are

found to be correct then proceed to the next stage

4. Remove the lid from the grey head terminal box and check terminals for loose

wires. If these are all found to be tight and the inputs are still incorrect, proceed to

next step.

5. Use a Digital volt meter (DVM) to check continuity of the circuit at the head

terminal box with the aid of the head box schematic.