Magnum Venus Plastech Megaject RTM Pro Revison 7_0 User Manual

Page 22

Megaject RTM Pro Manual – Revision 7.00 – 13

th

APRIL 2006

The injection parameters can be modified during the injection and the machine can be

paused or restarted, by pressing the STOP and START buttons respectively.

When the injection is paused, a FLUSH button appears at the bottom right of the

screen. To finish the injection the user must press the FLUSH button (see section 3.8)

to close any connected autosprues, return the head valves to the recirculate position

and to initiate the flush sequence.

3.7. Manual Head Pressure Controlled Injection

Once the sprue configuration has been set on the manual injection setup screen (see

section 3.5), the HEAD PRESSURE CONTROL button can be pressed to access the

manual injection screen for head pressure control, illustrated in Figure 3.3.

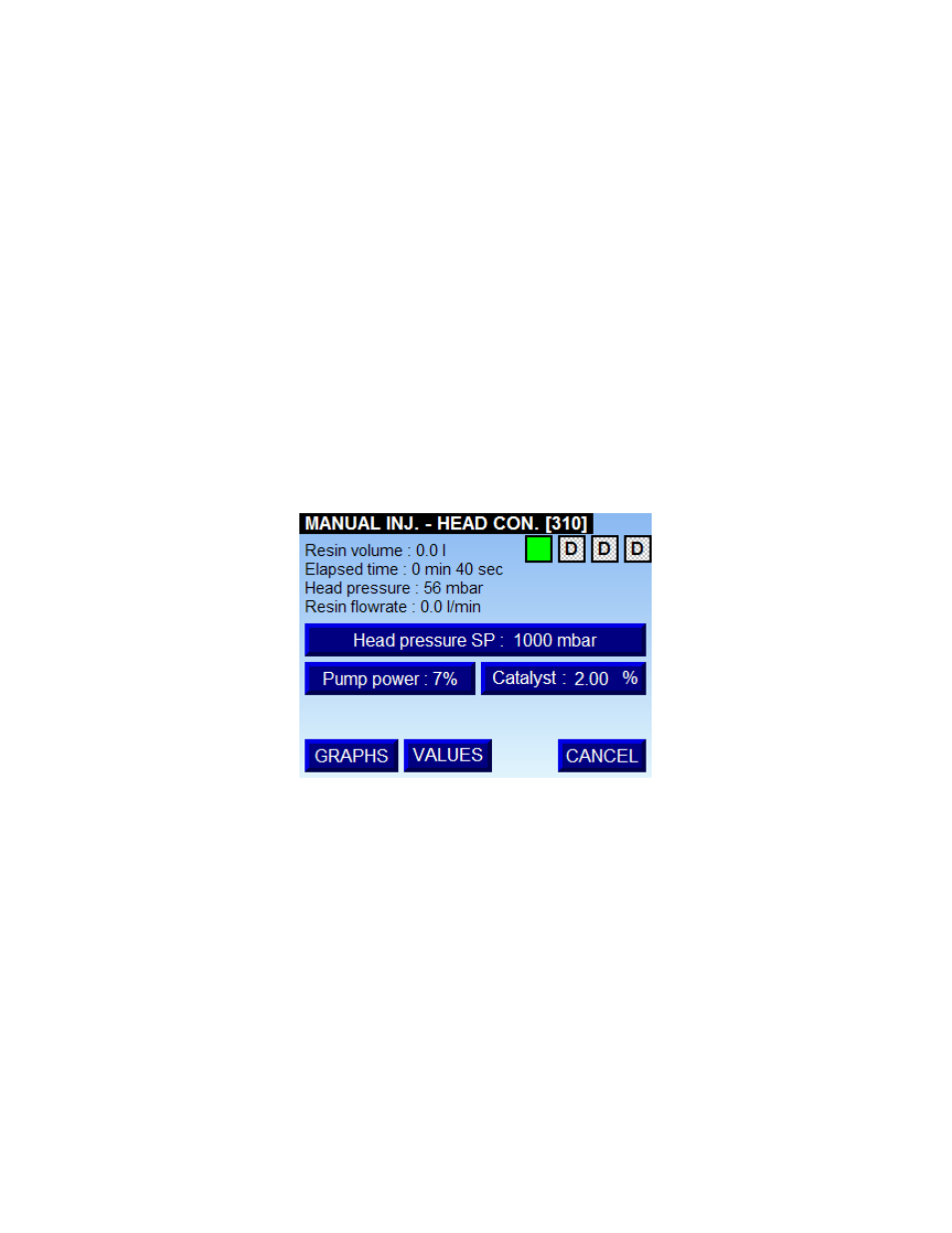

The four square indicators at the top right of screen illustrate the configuration of each

sprue, from left to right sprue 1 to sprue 4 respectively. A grey box containing a D

indicates the sprue is disabled. A green filled box indicates an enabled sprue; while a

green box, containing an L shows that the sprue is enabled with limit switch

monitoring.

Figure 3.3 – Manual injection screen, head control

The screen displays the volume of resin injected, elapsed time of injection, actual

head pressure and the current resin flow rate. The resin volume and elapsed time

readings retain there final values from the previous injection, which can be useful, and

are only reset when a new injection is commenced by pressing the START button.

Select the head pressure SP button to enter the desired head pressure for the injection.

A catalyst percentage between 0.5% - 4.5% can also be set.

The pump power value represents the maximum air pressure available to the air

cylinder operating the pumps. This can be adjusted to change the behaviour of the

machine and affects both the flow rate and response of the control system.

It is advised that an initially a low value (<10%) is chosen, and then adjusted to

optimise the performance of the system.