Magnum Venus Plastech Megaject RTM Pro Revison 7_0 User Manual

Page 15

Megaject RTM Pro Manual – Revision 7.00 – 13

th

APRIL 2006

When the machine is recirculating, it will run for 15 minutes and then rest for 1

minute using these settings. To stop the machine press the STOP button located on the

screen housing. The Catal bar should rise and fall to indicate catalyst flow, refer to

section 3.4 for further information.

Recirculate until a bubble free fluid flow is observed at both the resin and catalyst

containers, and pump output is even on both strokes. If any air is observed in either

return pipes press red STOP button and check tightness and vacuum security of all

intake pipe-work and fittings from containers to lower pump inlets.

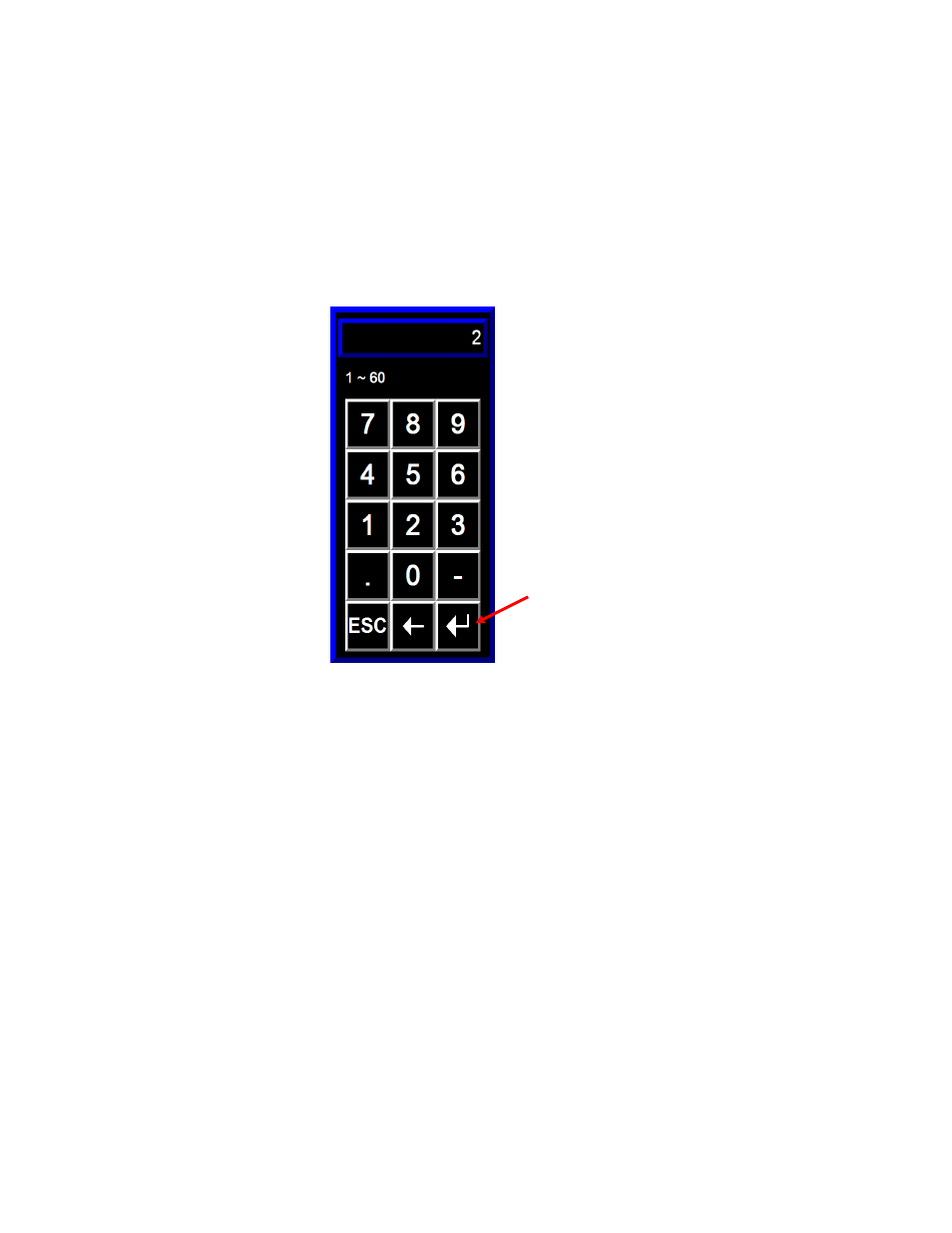

Figure 2.7 – Numeric input keypad

2.5. System Test

To check that the machine is working correctly, a manual head pressure controlled

injection should be carried out. Refer to section 3.5 and 3.7 for a detailed description

of how to run the machine in this mode.

In the manual injection setup screen, ensure all the sprues are disabled, and then press

the HEAD PRESSURE CONTROL button to navigate to the head pressure

controlled manual injection screen.

Enter the following values:

•

Head pressure SP = 1000mbar

•

Pump power = 15%

•

Catalyst = 2% (or other suitable value for the resin system being used)

Once the machine has been correctly configured, direct the injection nozzle into a

waste container.

Press the START button and dispense from the mixer at least 1 litre of fluid into the

waste container and then press STOP.

Return

key

(Enter)