Magnum Venus Plastech Megaject RTM Pro Revison 7_0 User Manual

Page 21

Megaject RTM Pro Manual – Revision 7.00 – 13

th

APRIL 2006

green box, containing an L shows that the sprue is enabled with limit switch

monitoring.

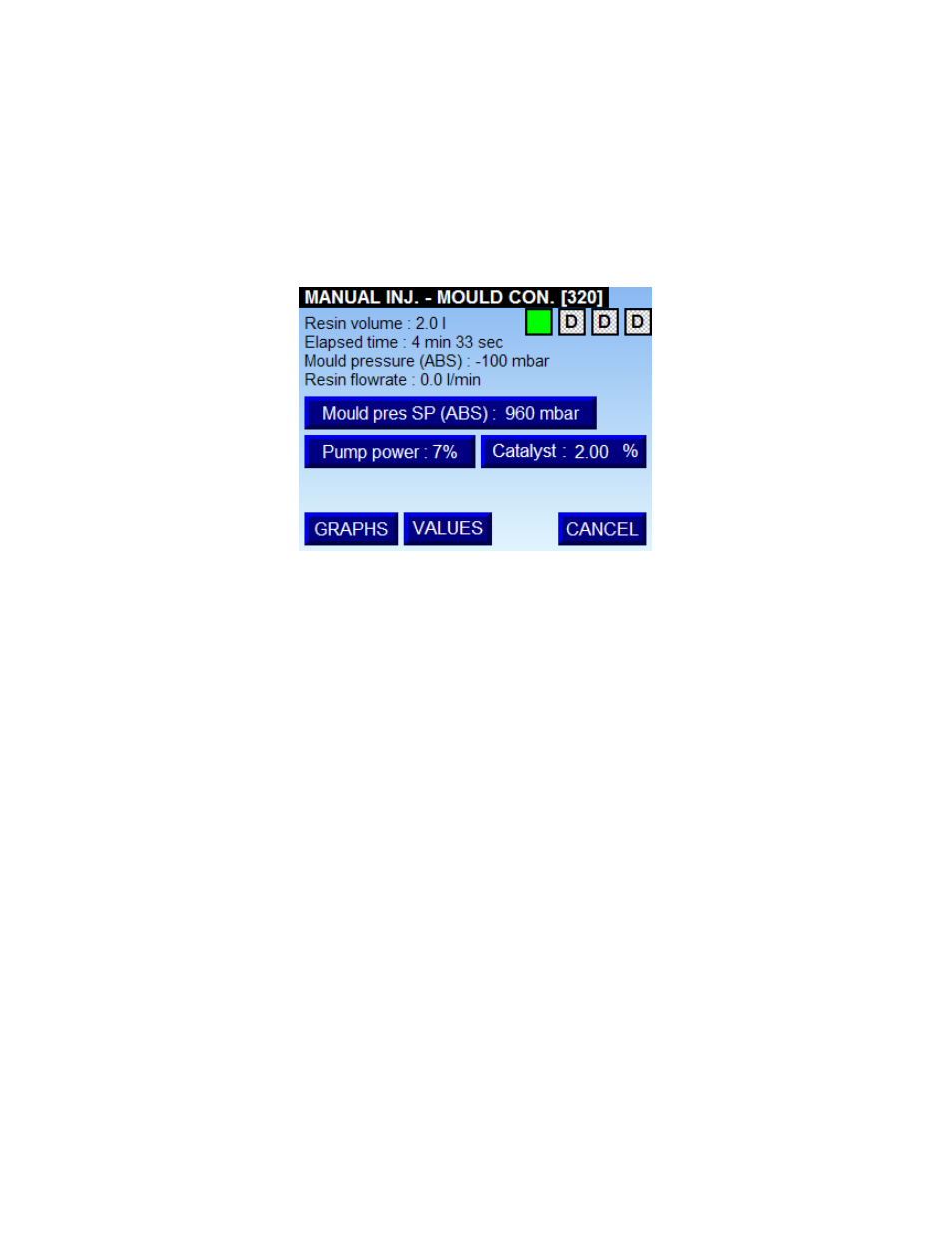

The screen displays the volume of resin injected, elapsed time of injection, actual

pressure in the mould cavity and the current resin flow rate. The resin volume and

elapsed time readings retain there final values from the previous injection, which can

be useful, and are only reset when a new injection is commenced by pressing the

START button.

Figure 3.2 – Manual injection screen, mould control

The mould pressure set point (SP) value is the desired pressure to be maintained in the

mould during the injection. This value is in mbar absolute, and for a typical LRTM

injection, it is suggested that good starting point would be to set this value to

approximately 100mbar below atmospheric pressure (around 910 mbar).

Pump power sets the maximum air pressure available to the air cylinder to drive the

resin and catalyst pumps. This value will vary depending on the type of resin used,

length of pipe to the mould and tooling design etc. It is recommended that a low

percentage is entered initially (<10%) and then modified based upon the response of

the machine.

During the initial phase of the injection, as resin is first introduced into the mould, the

mould pressure will take some time to build. At this time the flow rate will be mainly

determined by the pump power setting. If head pressure clipping is enabled (see

section 4.5), unsmooth operation of the pumps may indicate that the pump power

should be reduced. If head clipping is disabled, care should be taken not to over

pressurise the supply line by increasing the pump power value excessively.

The catalyst ratio can be changed to a value between 0.5% - 4.5%.

To begin the injection, press the START button. The sounder beacon will operate for

a period, to warn the operator that the machine is about to start. The catalyst pump

will then move to the position on the ratio arms specified by the current catalyst

percentage. At this point the head valves change over to the inject position, if enabled

any connected sprues are opened, and then the machine begins to inject.