Magnum Venus Plastech Megaject RTM Pro Revison 7_0 User Manual

Page 30

Megaject RTM Pro Manual – Revision 7.00 – 13

th

APRIL 2006

bar) for the head pressure SP, 2 litres for the required quantity of resin to inject

and 15% for the pump power setting. Press the right arrow button.

5.

On edit recipe screen 4, ensure that temperature compensation is disabled.

Press the right arrow button.

6.

On the final edit recipe screen, press the SAVE button to retain the settings

which have been entered. Press the OK button to finish creating the “2 litre

bucket” recipe.

3.10. Automatic Injections

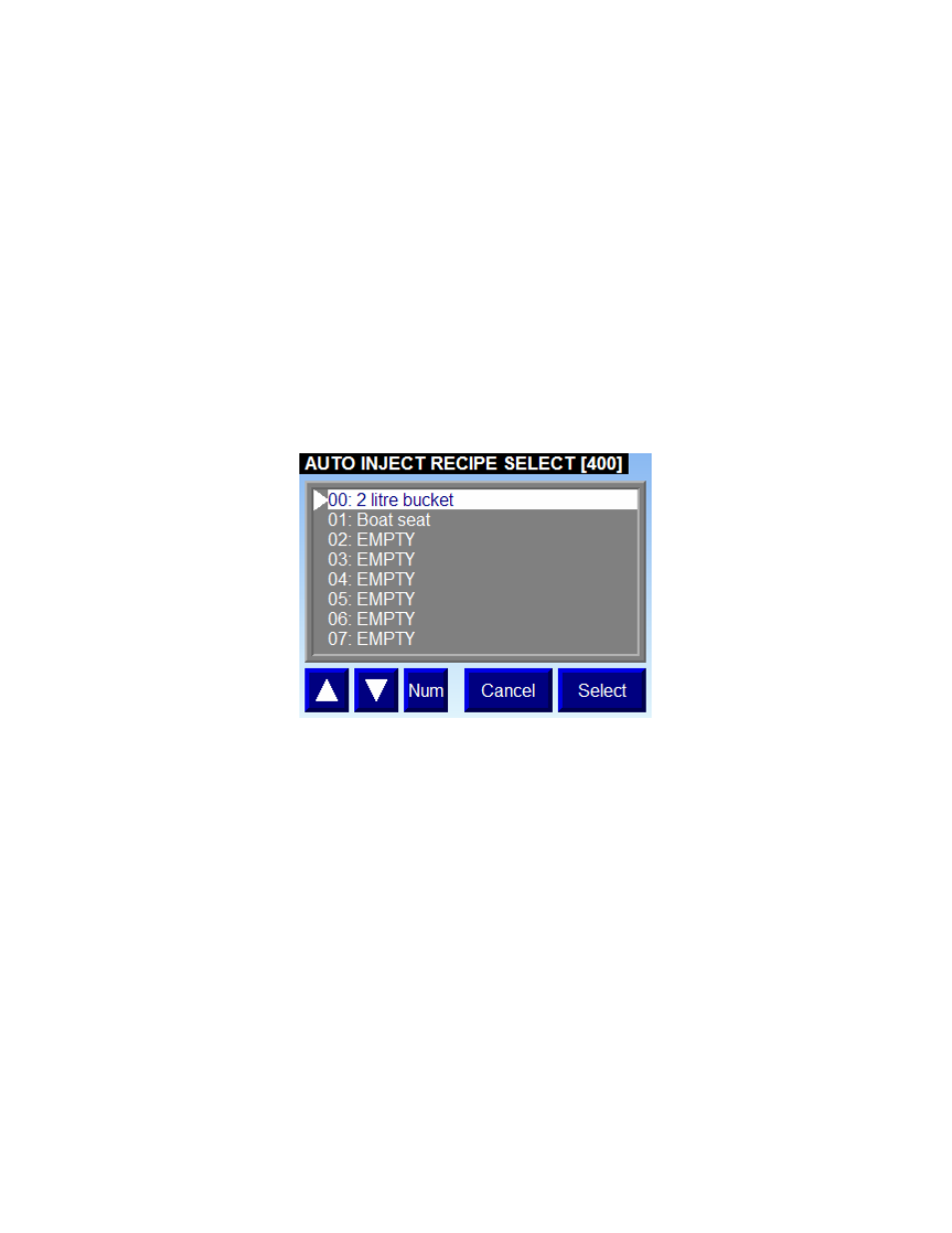

To perform an automatic injection, select the AUTOMATIC INJECTION button on

the main menu to navigate to the automatic injection recipe selection screen shown in

Figure 3.12. The currently selected recipe is highlighted with a white bar. To select a

different recipe, use the up or down arrows at the bottom left of the screen to scroll

through the list. If the number of the required recipe is known, the operator can also

select the recipe by pressing the NUM button and entering the recipe number. When

the correct recipe has been selected, press the SELECT button to proceed.

Figure 3.12 – Automatic injection recipe selection

When a recipe has been selected, the screen displayed will depend upon the type of

injection configured in the recipe; namely, mould pressure controlled or head pressure

controlled.

The screen displayed for head pressure control is shown in Figure 3.13. At the top

right of the display, four status indicators illustrate the sprue configuration of the

recipe, from left to right sprue 1 to sprue 4 respectively. A grey box containing a D

indicates the sprue is disabled. A green filled box indicates an enabled sprue; while a

green box, containing an L shows that the sprue is enabled with limit switch

monitoring. Care should be taken by the user, to ensure that these settings agree with

the hardware actually connected to the system.

Below the screen title, and sprue configuration indicators the name of the selected

recipe is displayed for operator reference.

The elapsed time timer begins running when the user starts the injection. This timer

continues to run until the injection has completed or been aborted by flushing the