Magnum Venus Plastech Megaject RTM Pro Revison 7_0 User Manual

Page 57

Megaject RTM Pro Manual – Revision 7.00 – 13

th

APRIL 2006

6.10. Progressive Catalyst Ratio (PCR) System

It should be ensured that the stepper motor assemblies used to position the catalyst

pump on the ratio arms are regularly maintained. All bolts should be correctly

tightened, with particular care that coupling between the motor shaft and catalyst

drive is tight. Failure to ensure this could result in slippage and misalignment of the

catalyst pump.

It should be noted that the top and bottom motors communicate with the PLC via an

RS485 bus, and have each been given a different addresses. Therefore, the motors can

not be interchanged. The top motor is has the address 1, while the bottom motor has

the address 2.

Motors can be supplied already addressed, or the address of the motor can set on site.

This must be done using specialised software running on a Laptop. Please contact

Plastech for further information.

A dedicated screen is provided on the machine to trouble shoot motor faults. Please

refer to section 6.11.1 for more information.

6.11. Maintenance screens

The machine has a number of screens which can be used to aid fault finding and

maintenance procedures. All of these screens can be accessed from the configuration

and maintenance screen, which can be selected by pressing the CONFIGURATION

& MAINTENANCE button on the main menu screen.

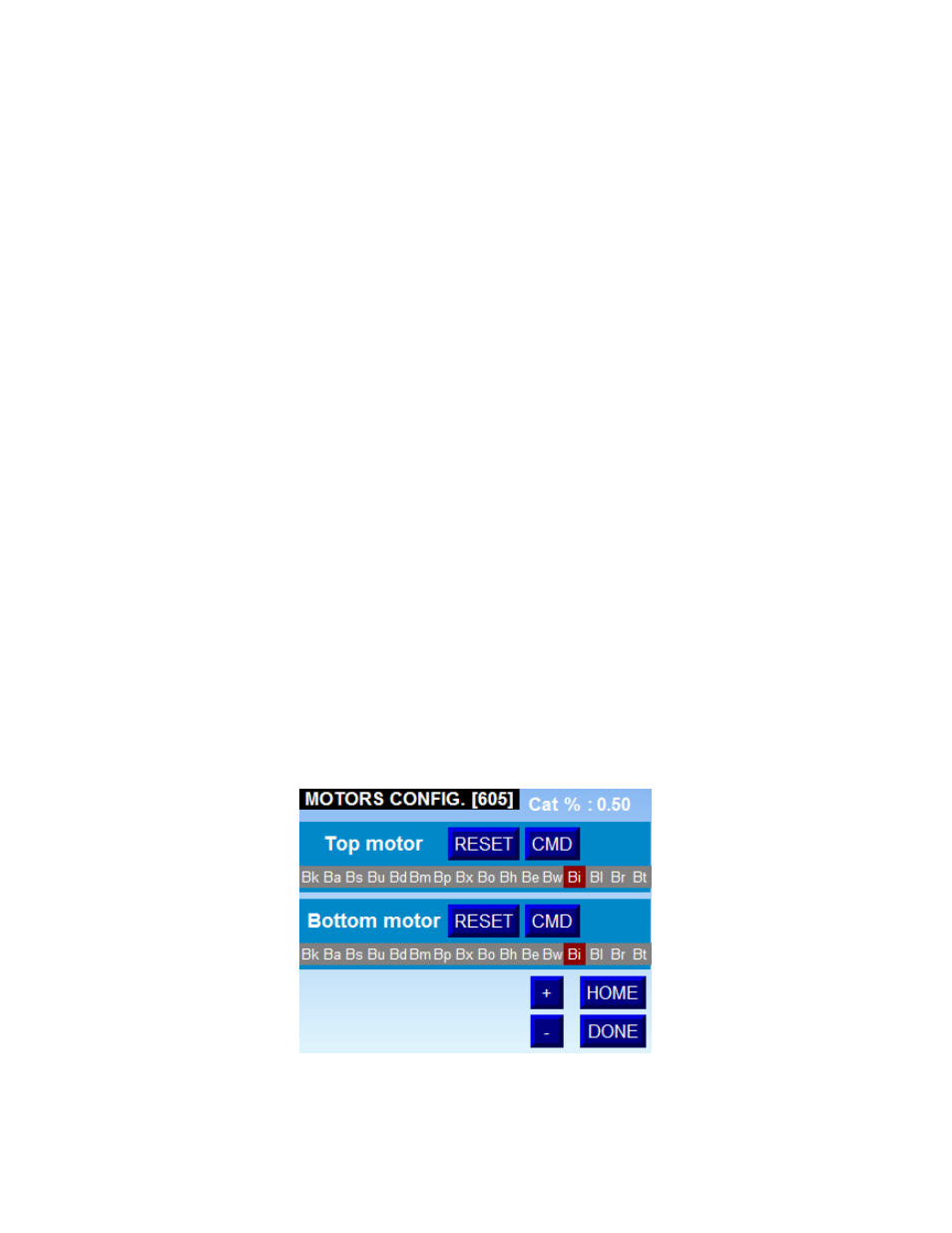

6.11.1. Motor configuration screen

The motor configuration screen, shown in Figure 6.11.1, should only be used with

caution. It is possible to damage or reconfigure the motors to prevent them working

with the system from this screen, if the CMD buttons are used incorrectly. It is

therefore recommended that the CMD buttons are only used by Plastech employees or

under guidance from a Plastech representative. If a CMD button is press accidentally

then simply cancel the pop up string entry dialogue, without pressing the enter key.

Figure 6.11.1 – Motors configuration screen