Magnum Venus Plastech HIS INSTRUCTION MANUAL User Manual

Page 18

- 18 - H.I.S. Instruction Manual

7. Slide catalyst pump to back of slave arm and re-insert quick pin into slave arm hole

just in front of catalyst pump bearing block. It should be general procedure never

to have the catalyst pump connected except when actually spraying a laminate.

Note: This will allow resin pump to stroke but prevent catalyst pump from

moving during start-up procedure.

8.

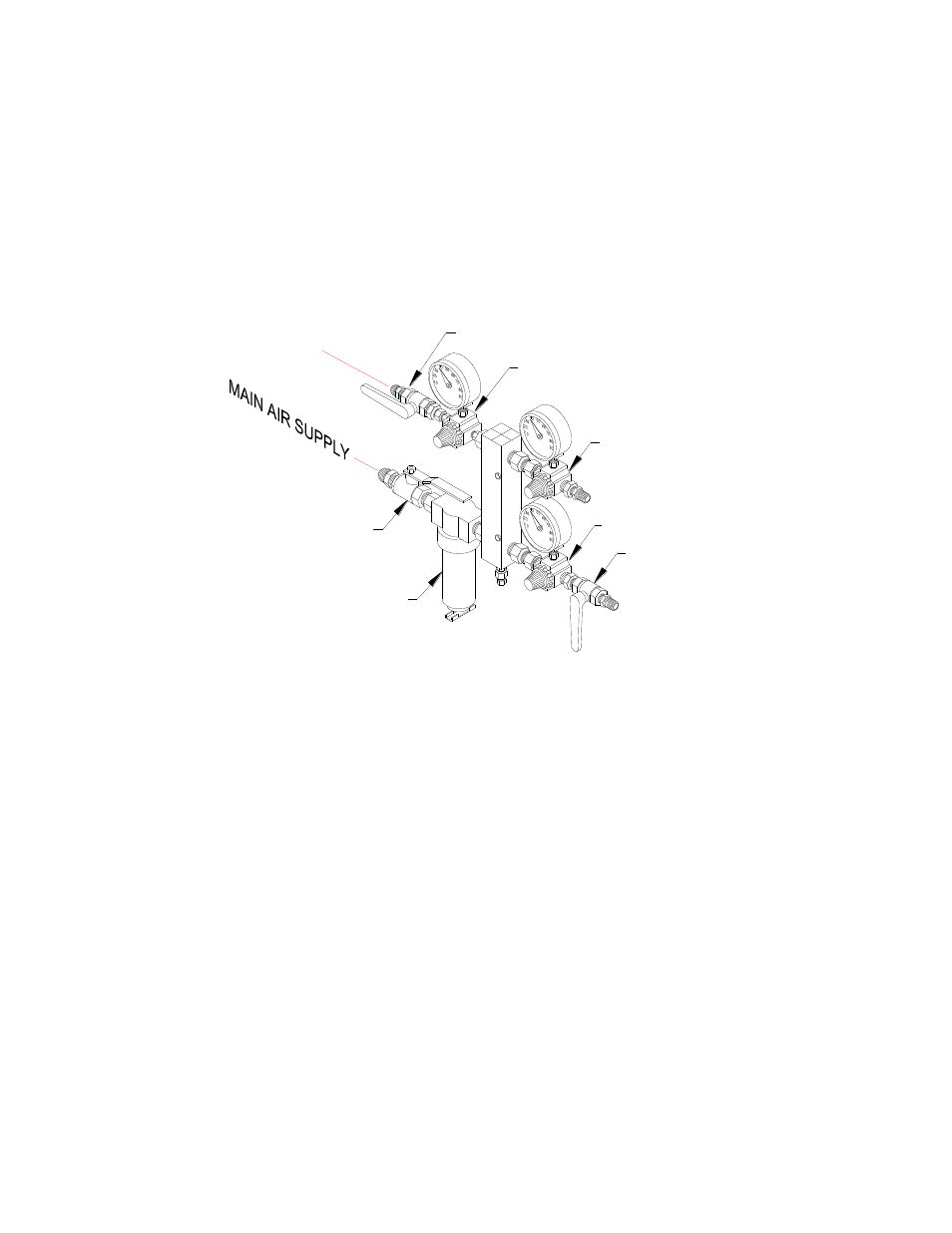

Attach air source to manifold fitting. Note ½” diameter (minimum) air hose should

be used for maximum efficiency. See Detail XIII.

FLUSH AIR CONTROL VALVE

FLUSH REGULATOR

CHOPPER REGULATOR

WATER TRAP

MAIN AIR SHUT OFF VALVE

RESIN PUMP AIR REGULATOR

RESIN PUMP AIR SHUT OFF VALVE

DETAIL XIII

9. Remove top from flush tank and fill with clean suitable solvent. Replace tank top.

(Acetone or Methylene Chloride preferred).

10. Slowly bring flush regulator up to 40 psi (turn clockwise).

Note: Flush Tank pressure should never be higher than 60 psi.

11. Slowly open flush air control valve.

12. Remove nozzle, nozzle cap, turbulent mixer and front resin plug from gun.

13. Push forward on gun trigger until solvent exits gun nozzle. Release trigger and

check entire flush system for leaks. To relieve pressure, turn flush air control valve

to off position and lift up on wire ring of relief valve located on top of flush tank.

Note: Release pressure from system before any corrective action takes place.

14. Make sure portable cart is properly assembled and supported using ballast where

necessary for other than standard units.

15. Place resin supply onto portable cart and insert resin wand into resin container.

Resin supply should be thoroughly mixed before being used. Central bulk resin

systems should have a filter between the resin supply and pump to prevent clogging.