Lap pad calibration & set-up, Before getting started – Liquid Controls LCR Setup & Operation User Manual

Page 9

9

Lap Pad Calibration & Set-Up

•

Make sure that the Lap Pad or other dat a entry device is connected to the LCR register as described in the LCR

Installation Manual.

•

When proving the LCR system, follow the pre-test and inspection procedures established by Weights & Measures

authorities. The primary indicating and recording element on a vehicle-mounted LCR is the 6-digit liquid cryst al

display.

•

Weights & Measures inspectors are responsible for determining if the truck metering and recording element

s of the

system are within tolerance. To make this determination, the system should be tested under normal conditions.

•

The LCR is pre-programmed with common values for many of the programmable p

arameters. These values should

be checked to ensure that they fit the specific requirement s of the given inst allation. Detailed instructions for

checking and changing these values follow later in this publication.

•

Changes cannot be made to metrologically significant dat a without first removing the Switchplate and it s associ-

ated Weights & Measures seal. The security level for each of the programming screens is defined in the following

table:

STEP 1: REMOVE THE LCR

SWITCHPLATE

•

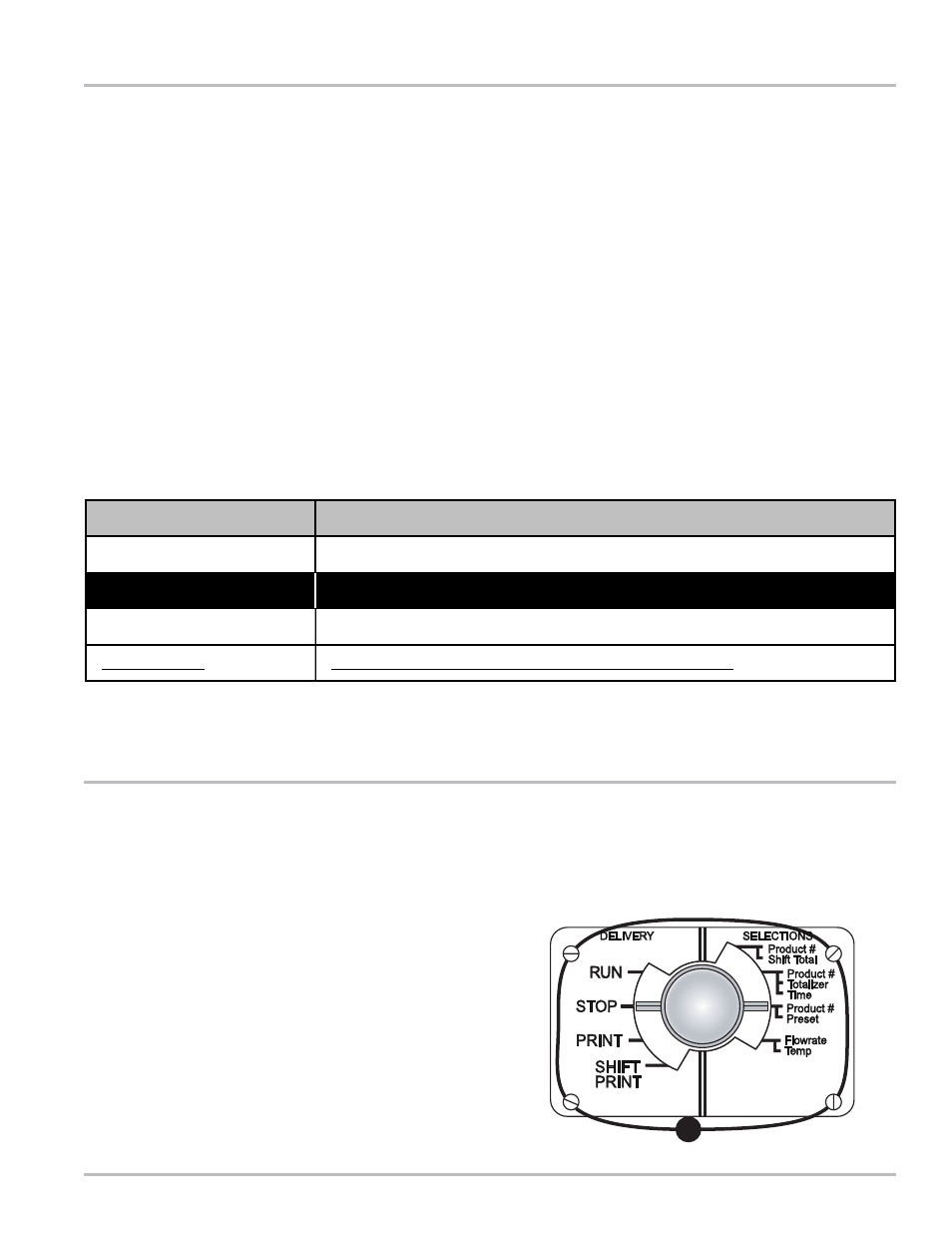

Remove the lead seal and wire assembly from the

LCR Switchplate (if previously sealed by Weights &

Measures authorities).

•

Remove the four screws that secure the Switch Plate

over the red Selector Switch located on the front of

the LCR, and remove the plate.

•

Rotate the Selector Switch counter clockwise to the

6 o'clock (CALIBRATION) position to permit access

to all programming fields (except FACTORY).

NOTE

: This table applies to the lower line of the Lap Pad display only. The upper line cannot be edited.

BEFORE GETTING STARTED

OPERATOR

Operato can change or enter data.

PASSWORD

System must be unlocked.

NOT EDITBLE

Read only (can not be changed by operator).

WEIGHTS & MEASURES

Switch must be in the CALIBRATION position to enter or

change data.

FACTORY

Read only (can not be changed by operator).