Lcr troubleshooting guide – Liquid Controls LCR Setup & Operation User Manual

Page 43

43

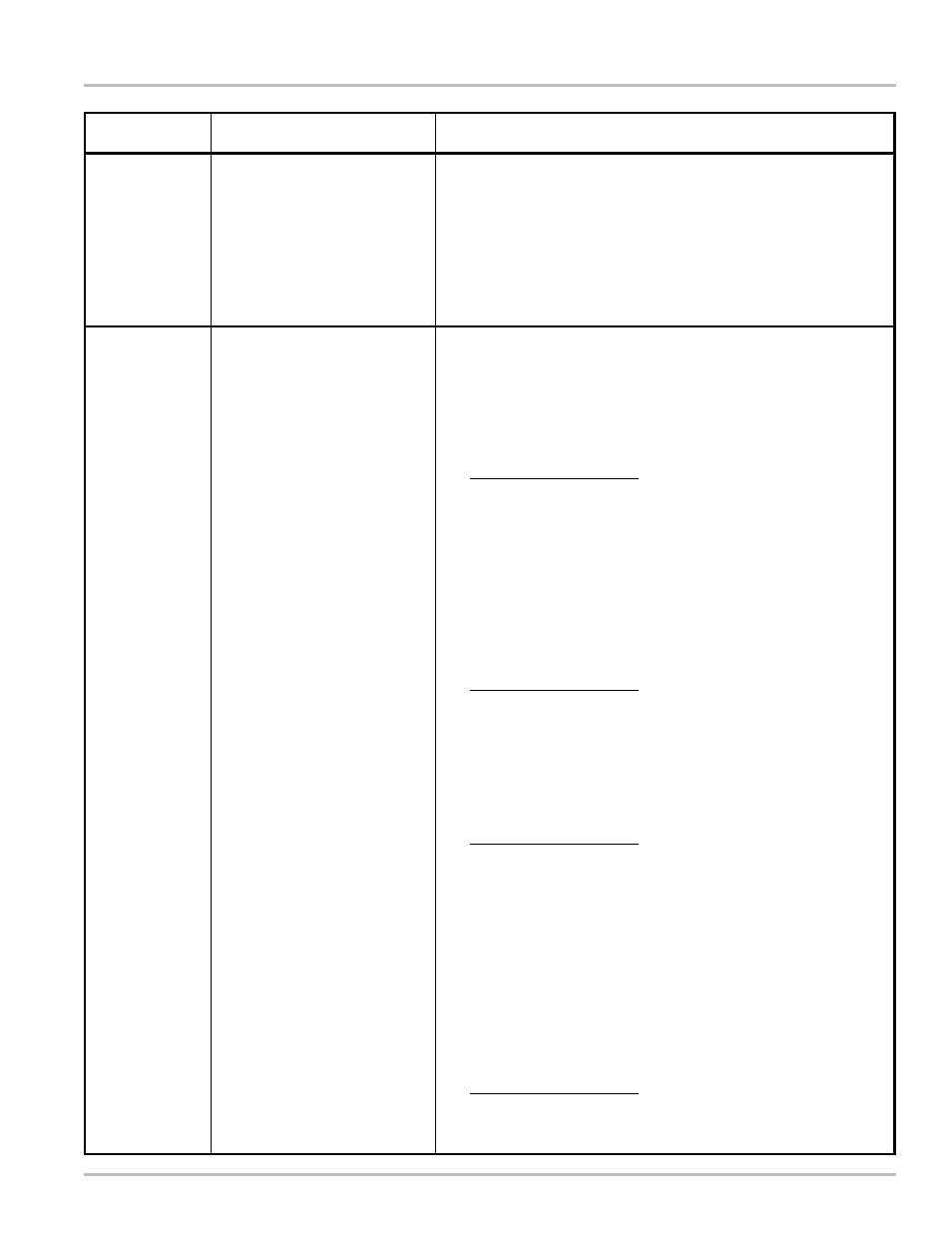

LCR Troubleshooting Guide

Pulser failure.

2. If the LCR display counter increments, this may indicate a

mechanical problem. Contact your local Liquid Controls

Service Center or the Liquid Controls Service Department for

assistance.

3. If the LCR display counter does not increment, see Pulser

Failure.

Missing pulse counts.

1. Check the pulser output.

Excessive reversals.

2. Open the LCR cover by loosening the single screw that holds

the cover closed. Using a reliable multimeter, measure the

following DC voltages on terminal block J8, while J8 is

connected to the circuit board. Use terminal #37 as ground

reference.

TERMINAL # VOLTAGE

J8 #32 +5 VDC

J8 #33 0 or +5VDC

J8 #34 0 or +5VDC

3. If the following voltages are observed, check for loose pulser

wiring connections. If no loose connections are found,

replace the encoder harness.

(Part # 81584 – for Series E2611X and E2612X)

(Part # 81412 – for Series E2605X and E2606X) or

(Hard wires for POD pulser.)

TERMINAL # VOLTAGE

J8 #32 0 VDC

J8 #33 +1-3VDC

J8 #34 +1-3VDC

4. Insert a ticket into the Epson printer. Begin a delivery. With

product flowing through the meter, measure the following DC

voltages on the terminal block.

TERMINAL # VOLTAGE

J8 #32 0 VDC

J8 #33 +1-3VDC

J8 #34 +1-3VDC

5. If the voltages shown below are observed, ensure that the

pulser shaft is rotating. Look for any mechanical problems

that may cause either the meter or the pulser shaft to lock up.

If the Lap Pad continues to indicate a pulser failure, replace

the pulser.

(Part # 81582 for Series E2611X and E2612X)

(Part # 81170 for Series E2605X and E2606X) or

(Part # 81159 for POD pulser)

TERMINAL # VOLTAGE

J8 #32 +5 VDC

J8 #33 0 or +5VDC

J8 #34 0 or +5VDC

SOLUTION

PROBABLE CAUSE

PROBLEM

Product flow

does not register

on Lap Pad or

LCR display

“Pulser Failure”

appears on the

diagnostic ticket

or on the Lap

Pad display.

NOTE: Pulser faults generally

occur in a high vibration

environment. Liquid Controls is

not responsible for pulser

failures caused by excessive

system vibrations.

Pulser shaft is not turning with

product flow.

Manually spin the pulser shaft and monitor the LCR display.

1.