Lcr troubleshooting guide – Liquid Controls LCR Setup & Operation User Manual

Page 41

41

NOTE

: Check for proper operating voltages before changing the circuit board. If the circuit board needs to be changed,

be sure to remove all power to the LCR.

5. If an error occurs during a delivery , the message "* FAULT: PRINT DIAGNOSTICS TICKET*" will appear on the

delivery ticket. The diagnostic ticket will contain an error message that can be useful in troubleshooting. Print a

diagnostic ticket

by moving the red Selector Switch to " SHIFT PRINT" for less than two seconds. Examine the

diagnostic ticket to make sure all set-up fields are accurate, e.g. pulses per unit volume, temperature coef ficient

and base temperature.

6. NEVER remove a terminal block or jumper with the power on.

7. NEVER install a terminal block or jumper with the power on.

8. NEVER force a terminal block into its location.

9. NEVER exchange or reposition terminal blocks on the circuit board.

10. In case of a major problem such as a burned or water-damaged circuit board, evaluate possible causes before

replacing it and turning the power back on.

11. Isolate the problem before changing the circuit board.

12. Return faulty circuit boards with the proper forms, concisely completed.

There may be several probable causes for a system malfunction. Listed on the next four pages are several probable

causes to aid in returning the system to operation as quickly as possible.

The list is not all-inclusive and should only be

used as a guide.

LCR Troubleshooting Guide

1. With the key in the accessory position, check the battery

voltage to the circuit board at J6. Use terminal #11 as positive

and terminal #12 as DC ground. While the LCR will power-up

at +9VDC, it is recommended that the input be at least

+12.6VDC. Ref

2. Check the 7.5A, in-line fuse (Part # 70985) for continuity. It is

located in the accessory power line. Replace if necessary.

1. For safety reasons, remove the 7.5A, in-line fuse from the

accessory power cable.

2. Remove the 3-pin power connector J6. Inspect for stray wire

stands and visible shorts.

3. Inspect the full length of the power cable. Look for damaged

insulation, which may cause shorting between the cable and

ground potential (e. g. truck frame or chassis). If the power

cable (Part # 81512) is damaged, it must be replaced.

4. Replace the 7.5A fuse (Part # 70985) and re-install the J6

connector.

5. If the 7.5A fuse blows again, replace the LCR circuit board.

6. If the 7.5A blows after the LCR circuit board has been

replaced, then replace the power cable (Part # 81512).

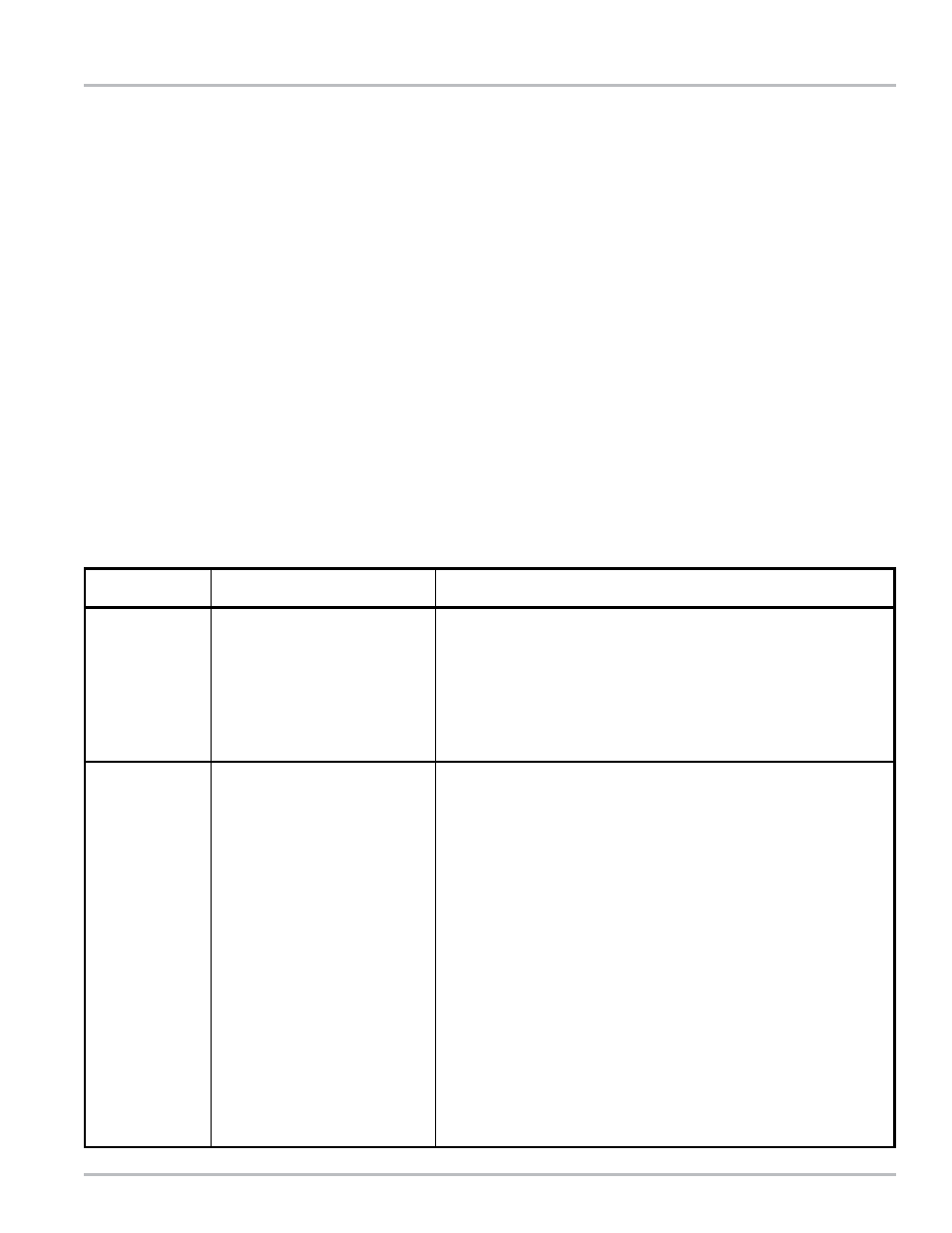

PROBLEM

PROBABLE CAUSE

SOLUTION

Unit will not

power up or

there is no

display.

Inadequate supply voltage.

+9 to 28VDC is required for

operation.

Unit blows 7.5A

fuse.

+12VDC Battery line is

shorted to ground