2 v ersion, 3x v ersion – GF Signet 2552 Metal Magmeter Flow Sensor User Manual

Page 9

9

2552 Magmeter

7. Calibration

Data

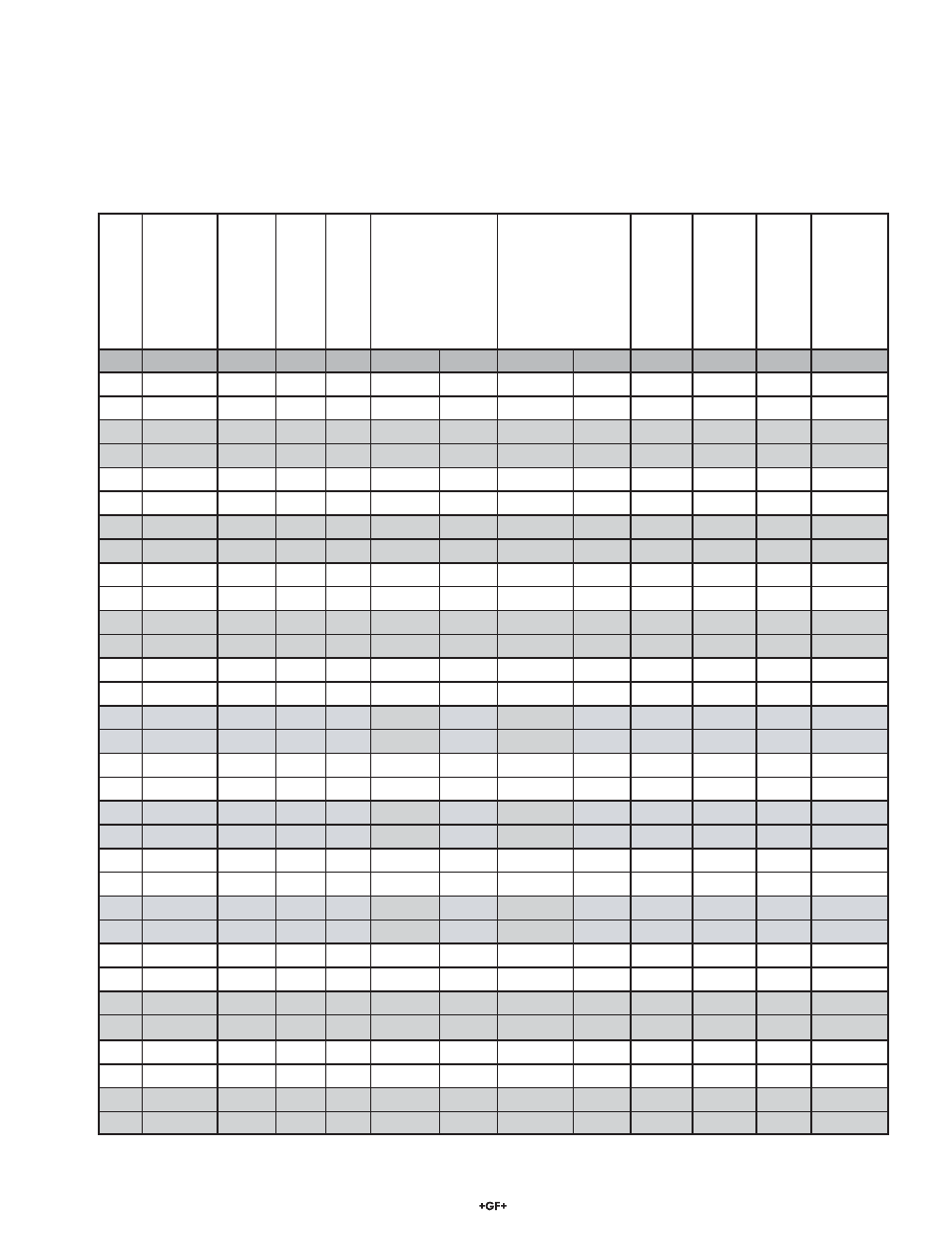

7.1 K-factors and Full Scale Current Values for 3-2552-2x - x - xx and 3-2552-3x - x - xx Magmeters

Pipe Size (ANSI)

Schedule

OD (Inches)

W

ALL

(Inches)

ID (Inches)

H Dim

-2 V

ersion

H Dim mm

-3X V

ersion

K-Factor

Pulse/liter

K-Factor

Pulse/Gal

Factory set

20 mA

(liter/min)

Factory set20

mA

(GPM)

Inch

mm

Inch

mm

2

40

2.375

0.15

2.07

10 16/32

267.0

16 5/32

409.9

46.19

174.83

649.5

171.6

80

2.375

0.22

1.94

10 15/32

265.9

16 3/32

408.6

52.49

198.68

571.5

151.0

2½

40

2.875

0.20

2.47

10 14/32

264.9

16

407.7

32.37

122.54

926.7

244.8

80

2.875

0.28

2.32

10 12/32

263.4

16

406.2

36.57

138.42

820.3

216.7

3

40

3.500

0.22

3.07

10 12/32

263.1

15 31/32

405.8

20.97

79.36

1431

378.0

80

3.500

0.30

2.90

10 9/32

261.4

15 29/32

404.1

23.47

88.82

1278

337.8

3½

40

4.000

0.23

3.55

10 10/32

261.6

15 29/32

404.4

15.68

59.34

1914

505.6

80

4.000

0.32

3.36

10 8/32

259.7

15 27/32

402.5

17.44

66.01

1720

454.5

4

40

4.500

0.24

4.03

10 8/32

260.1

15 28/32

402.9

12.18

46.09

2464

651.0

80

4.500

0.34

3.83

10 5/32

258.1

15 25/32

400.9

13.48

51.03

2225

587.9

5

40

5.563

0.26

5.05

10 4/32

257.0

15 24/32

399.7

7.748

29.33

3872

1023

80

5.563

0.38

4.81

10

254.6

15 21/32

397.4

8.519

32.25

3521

930.4

6

40

6.625

0.28

6.07

10

253.8

15 20/32

396.6

5.365

20.31

5591

1477

80

6.625

0.43

5.76

9 28/32

250.8

15 16/32

393.5

5.946

22.51

5045

1333

8

40

8.625

0.32

7.98

9 24/32

247.9

15 12/32

390.7

3.098

11.73

9683

2558

80

8.625

0.50

7.63

9 20/32

244.3

15 8/32

387.0

3.394

12.85

8838

2335

10

40

10.75

0.37

10.0

9 16/32

241.6

15 4/32

384.4

1.966

7.440

15262

4032

80

10.75

0.59

9.56

9 11/32

237.00

14 30/32

379.8

2.158

8.170

13899

3672

12

STD

12.75

0.38

12.0

9 10/32

236.4

14 30/32

379.1

1.371

5.187

21890

5783

XHY

12.75

0.50

11.8

9 6/32

233.8

14 26/32

376.6

1.429

5.410

20987

5545

14

30

14.00

0.38

13.3

9 6/32

233.2

14 26/32

375.9

1.124

4.255

26688

7051

XHY

14.00

0.50

13.0

9 3/32

230.6

14 22/32

373.4

1.168

4.420

25690

6787

16

30

16.00

0.38

15.3

9

228.1

14 19/32

370.8

0.849

3.212

35352

9340

40/XHY

16.00

0.50

15.0

8 28/32

225.6

14 16/32

368.3

0.877

3.320

34202

9036

18

STD

18.00

0.38

17.3

8 25/32

223.0

14 13/32

365.8

0.663

2.510

45233

11950

XHY

18.00

0.50

17.0

8 22/32

220.5

14 10/32

363.2

0.683

2.585

43931

11610

20

20/STD

20.00

0.38

19.3

8 19/32

217.9

14 6/32

360.7

0.533

2.016

56330

14880

30/XHY

20.00

0.50

19.0

8 16/32

215.39

14 3/32

358.1

0.547

2.069

54876

14500

22

20/STD

22.00

0.38

21.3

8 12/32

212.85

14

355.6

0.437

1.654

68643

18136

30/XHY

22.00

0.50

21.0

8 9/32

210.31

13 29/32

353.1

0.448

1.694

67037

17711

24

20/STD

24.00

0.38

23.3

8 6/32

207.77

13 26/32

350.5

0.365

1.382

82172

21710

XHY

24.00

0.50

23.0

8 3/32

205.23

13 22/32

348.0

0.373

1.412

80414

21246

The data in these tables is based on dimensions of metal pipe per ANSI 36.10 and ANSI 36.19.

Stainless steel and carbon steel pipe schedules have the same dimensions according to ANSI standards.

Contact the local Georg Fischer Signet distributor for assistance with pipe sizes and materials not listed.