Selecting a location – GF Signet 2552 Metal Magmeter Flow Sensor User Manual

Page 3

3

2552 Magmeter

3. Selecting a Location

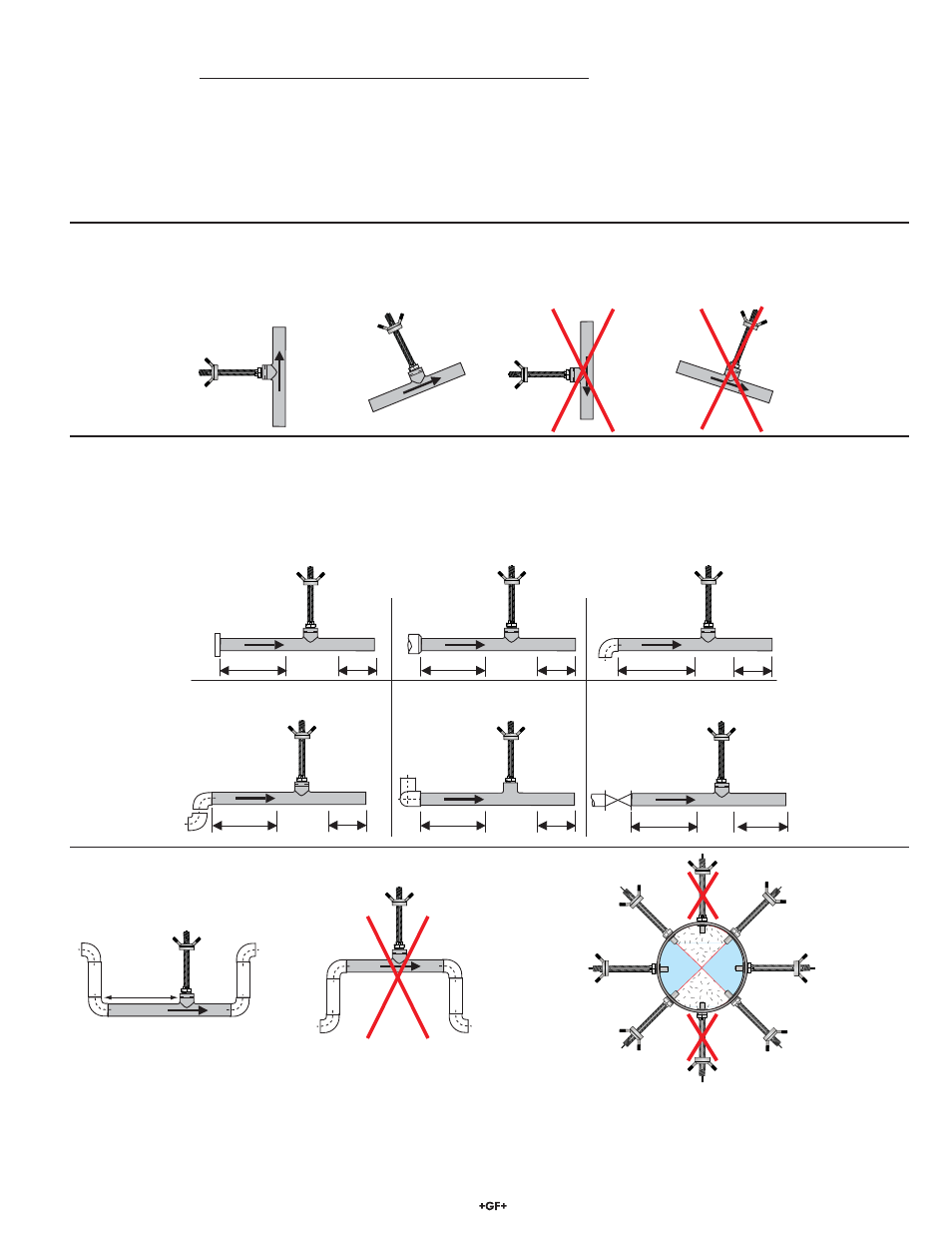

The 2552 requires a fully developed turbulent fl ow profi le for accurate measurement. Selecting the correct location in the piping system

is critical to the performance of the magmeter.

Locate the magmeter where air bubbles will not contact the electrodes.

Placing the sensor in a vertical section of pipe, with fl ow going UPHILL is the fi rst choice for this requirement.

The piping system should be designed to keep the sensor wet at all times.

In applications where the conductivity of the process liquid is less than 100

μS, magmeters should be allowed to soak in a full pipe for

24 hours before operation.

3.1 Vertical Installations Recommended

Locating the sensor where the fl ow is upward protects the sensor from exposure to air bubbles and may offset upstream turbulence

caused by pipe conditions and other hardware.

+GF+

15 x I.D.

5 x I.D.

Reducer

+GF+

10 x I.D.

5 x I.D.

Inlet

Outlet

Flange

+GF+

50 x I.D.

5 x I.D.

Valve/Pump

+GF+

40 x I.D.

5 x I.D.

2 x 90° Elbow

3 dimensions

25 x I.D.

5 x I.D.

2 x 90° Elbow

+GF+

20 x I.D.

5 x I.D.

90° Elbow

+GF+

+

GF

+

O.K.

+GF

+

O.K.

+GF+

O.K.

20 x ID

+GF+

+

GF

+

+GF

+

3.2 Horizontal

Installations

If the magmeter must be mounted in a horizontal section of pipe, take extra precautions to prevent air bubbles from passing over the

sensor.

Select a location with suffi cient distance of straight pipe immediately upstream of the sensor. The dimensions illustrated here are

intended for general guidance. Every piping system has unique characteristics, and requires individual evaluation.

Located the magmeter in a "trap" to prevent air bubbles and to

keep the electrodes wetted for best performance.

Air pockets and bubbles will travel at the top of a horizontal pipe,

so avoid vertical installations.

Sediments and debris that collect at the bottom of a horizontal

pipe will interference with the operation.