Sensor selection guide – GF Signet 2552 Metal Magmeter Flow Sensor User Manual

Page 13

13

2552 Magmeter

Sensor Selection Guide

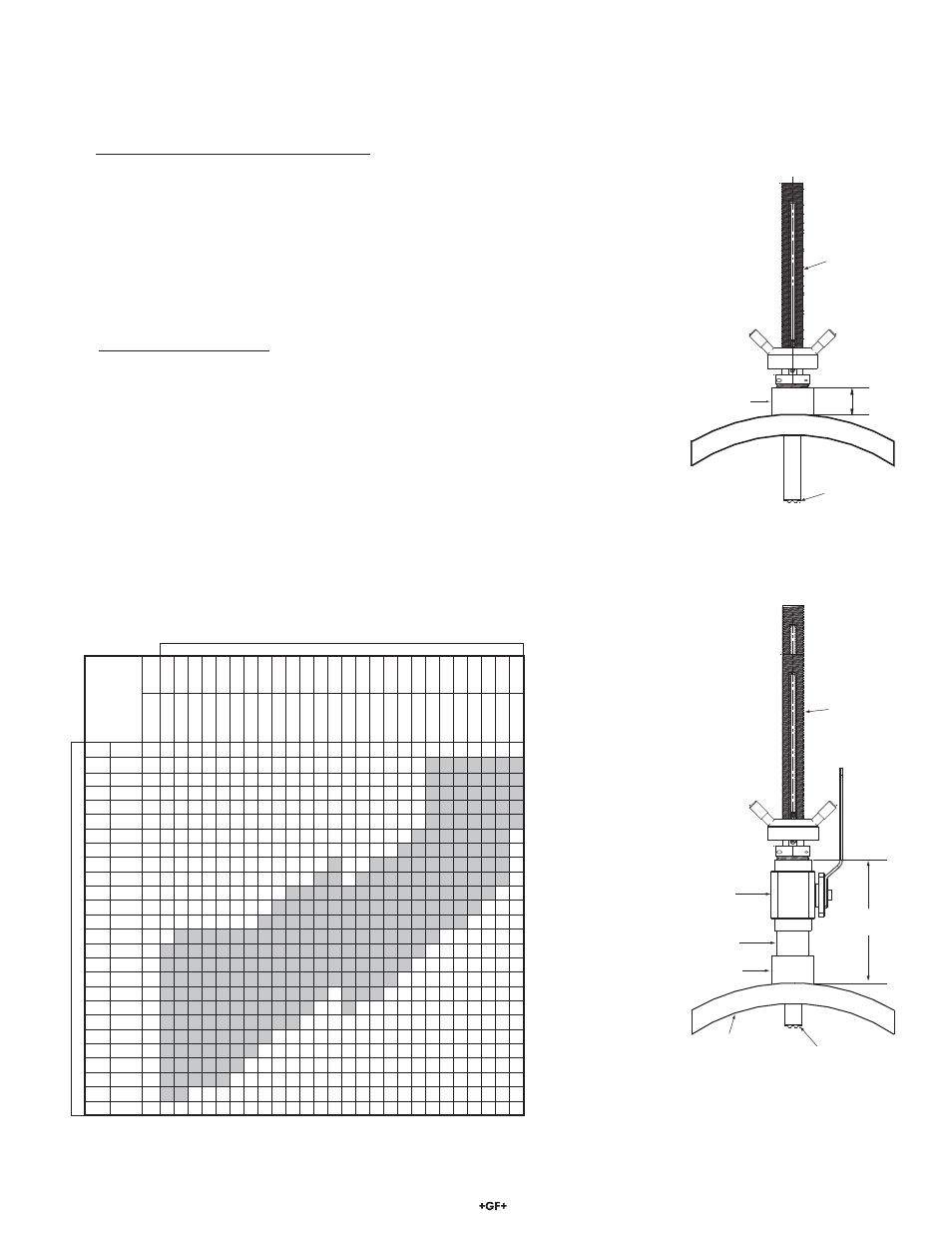

The 2552 Magmeter can be installed into a variety of pipe sizes. Follow the steps below

to ensure that you choose the right sensor for your application.

Step 1: Determine how the sensor will be installed

• For retrofit installations, the ball valve

must be at least a 1¼ in. (or 1½ in.

for 2552-3) full port valve. The stack

height, or “A” dimension (see Fig. 2), is

the overall height from the top of the

pipe to the top of the ball valve, or the

top of the highest point of the stack

before the sensor is connected.

B. For Hot-Tap installations:

The stack height of the ball valve, nipple weldolet (threadolet) and pipe adapters should

be determined before the sensor is purchased.

• For new installations, Signet

recommends a 1¼ in. or 1½ in. full

port ball valve, a short nipple and

a weldolet (threadolet). The stack

height or “A” dimension (see Fig. 2) is

the overall height from the top of the

pipe to the top of the ball valve.

A. For standard (non Hot-Tap) installations:

The height of the weldolet (threadolet) and pipe adapter(s) should be determined before

the sensor is purchased.

• For retrofit installations, the stack

height, or “A” dimension (see Fig. 1), is

the overall height from the top of the

pipe to the highest point of the stack

before the sensor is connected.

• For new installations, Signet

recommends a weldolet (threadolet)

and an adapter to accommodate the

1¼ in. (or 1½ in. for 2552-3) sensor

process threads. The stack height,

or “A” dimension (see Fig. 1), is the

overall height from the top of the pipe

to the highest point of the stack.

Step 2: Determine how the sensor will be installed

Once the “A” dimension is determined, go to the sensor selection table and find your “A”

dimension on the left column. Next, find the appropriate pipe size at the top of the chart.

To determine the correct sensor size locate where the pipe size column meets the max

“A” dimension row.

“A”

Dimension

Weldolet

or Saddle

Sensor

Housing

Sensor

Fig. 1

Standard installation with “A”

dimension using a weldolet

(threadolet)

“A”

Dimension

Weldolet

Nipple

Ball

Valve

Pipe

Wall

Sensor

Housing

Sensor

Fig. 2

Hot-Tap installation with “A”

dimension using a ball valve,

short nipple and weldolet

(threadolet)

Step 3: Refer to Ordering Information to select corresponding part numbers

Legend:

2: Use 3-2552-2,

max. insertion =

236 mm (9.3 in.)

3: Use 3-2552-3

max. insertion =

368 mm (14.8 in)

in

ches

2

2.

5

3 to 31/

2"

4

5

6 to 8"

10

12 to 14"

16

18

20

22

24

26 to 28"

30 to 32"

34

36 to 38"

40 to 42"

48

54

60

66

72

78

84

102

DN

50

65

80 to 90

100

125

150 to 200

250

300 to 350

400

450

500

550

600

650 to 700

750 to 800

850

900 to 950

1000 to 1100

1200

1400

1500

1700

1800

2000

2100

2550

mm

inches

50.8

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

3

3

3

3

3

3

3

63.5

2.5

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

3

3

3

3

3

3

3

76.2

3

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

3

3

3

3

3

3

3

88.9

3.5

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

3

3

3

3

3

3

3

101.6

4

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

3

3

3

3

3

3

3

114.3

4.5

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

3

3

3

3

3

3

3

127

5

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

3

3

3

3

3

3

3

3

139.7

5.5

2

2

2

2

2

2

2

2

2

2

2

2

3

2

2

3

3

3

3

3

3

3

3

3

3

152.4

6

2

2

2

2

2

2

2

2

2

2

2

3

3

2

3

3

3

3

3

3

3

3

3

3

3

165.1

6.5

2

2

2

2

2

2

2

2

2

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

177.8

7

2

2

2

2

2

2

2

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

190.5

7.5

2

2

2

2

2

2

2

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

228.6

9

2

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

241.3

9.5

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

254

10

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

266.7

10.5

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

279.4

11

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

292.1

11.5

3

3

3

3

3

3

3

3

3

3

3

3

304.8

12

3

3

3

3

3

3

3

3

3

3

317.5

12.5

3

3

3

3

3

3

3

3

330.2

13

3

3

3

3

3

3

3

342.9

13.5

3

3

3

3

3

3

355.6

14

3

3

3

3

3

375.9

14.8

3

3

381

15

Pipe Size

Ma

x

. "A

" D

im

This chart is based on the thickest commonly available pipe.