Burkert Type 3236 User Manual

Page 36

36

Repairs

Type 2035 / 3236

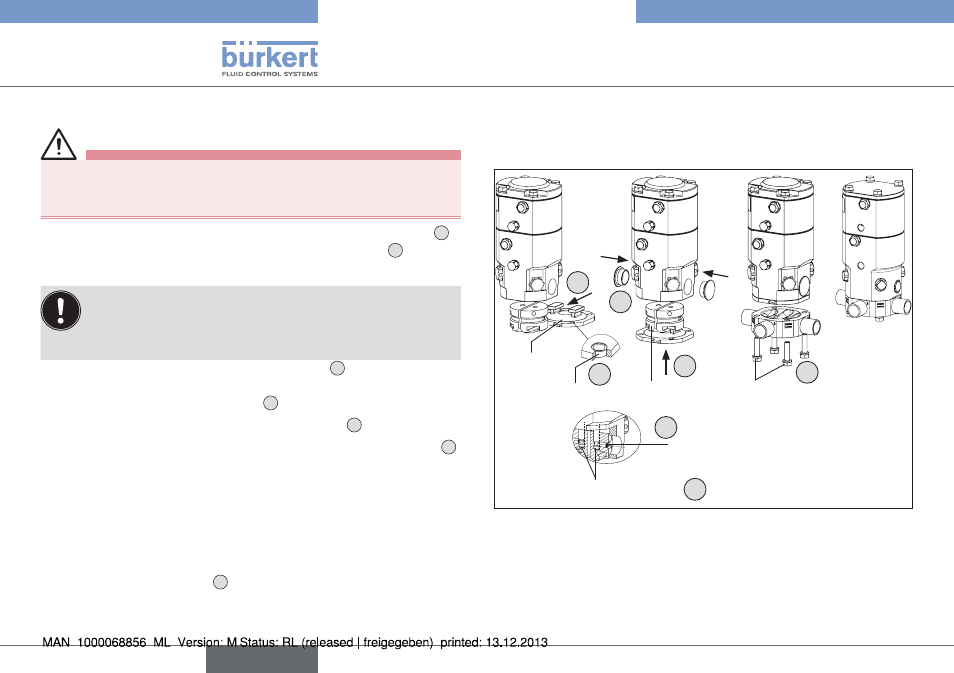

assembly of actuator and diaphragm

Caution!

danger of injury due to movable parts in the actuator.

▶ When applying or removing the pilot pressure on the actuator

keep members and other objects away from the actuator openings.

→

Insert the diaphragm into the T-guide of the pressure pieces

6

.

Make sure that the four spacing sleeves are installed

7

(RV70 only).

For easier assembly of the pressure pieces the actuator

spindles should be in the lower position (

Close) (CFA, NC:

by removing the pilot pressure; CFB, NO: by applying the

pilot pressure).

→

Insert the pressure pieces into the actuator

8

. Make sure that

the actuator spindles are fully inserted into the corresponding

recesses of the pressure pieces

9

.

→

Tighten the setscrews on the pressure pieces

10

.

→

Close the covers (for RV50 with PP cover: muffler and screw)

11

.

→

Move the actuator to the upper actuator position (CFA, NC: by

applying pilot pressure; CFB, NO: by removing the pilot pressure).

→

Put the actuator / diaphragm on the body with correct alignment

(so that the markings made previously align).

→

Tighten the diagonally opposed body screws / nuts until there

is visible, uniform mechanical contact between the valve body,

diaphragm and actuator

12

.

→

Tighten the diagonally opposed body screws / nuts twice with a

quarter turn and using the same torque in each case.

→

CFA, NC actuators: Remove the pilot pressure.

Body screws

Pressure pieces

Diaphragm

12

11

8

6

Setscrew

10

Actuator spindles

9

Spacer sleeve

7

Fig. 31: Assembly of the RV50, RV70 pneumatic actuators

english