Burkert Type 3236 User Manual

Page 34

34

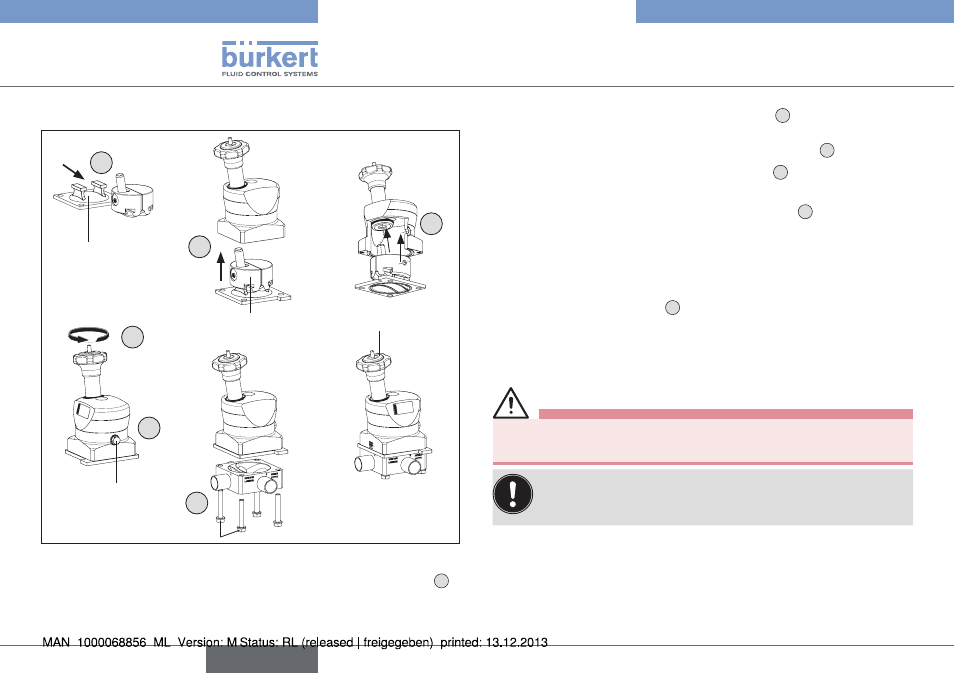

Repairs

Type 2035 / 3236

assembly of actuator and diaphragm

Body screws

Hand wheel

Pressure pieces

Diaphragm

Screw

10

11

9

7

6

8

Fig. 29: Assembly of manually operated single actuator

→

Insert the diaphragm into the T-guide of the pressure pieces

6

.

→

Insert the pressure piece into the actuator

7

. the following: The thread of the pressure piece spindle and the 8 . → Turn the hand wheel to the Open position 9 . → Position and tighten the screw (for RV50 Allen-type, for RV70/ 10 . → Put the actuator / diaphragm on the body with correct alignment → Tighten the diagonally opposed body screws / nuts until there 11 . → Tighten the diagonally opposed body screws / nuts twice with a test for leak-tightness / valve function Warning! danger of injury through egress of flow medium. ▶ Tighten the body screws / nuts sufficiently. Applying an unnecessary degree of force to tighten the shortens the service life of the diaphragm. If the valve leaks when the medium pressure rises: → Tighten the diagonally opposed body screws / nuts by a one- This procedure ensures that the diaphragm and the pressure piece english

hand wheel spindle must engage with each other

RV110 hexagonal) on the side of the actuator

(so that the markings made previously align).

is visible, uniform mechanical contact between the valve body,

diaphragm and actuator

quarter turn and using the same torque in each case.

body screws / nuts leads to increased wear and therefore

eighth turn until the valve no longer leaks.

are optimally aligned to each other and the valve function is ensured.