2 reassembly procedure – Alpha Technologies AlphaGen 3.5_5.0kW Kohler COM5 User Manual

Page 65

TP-6482 8/06

65

Section 7 Disassembly/Reassembly

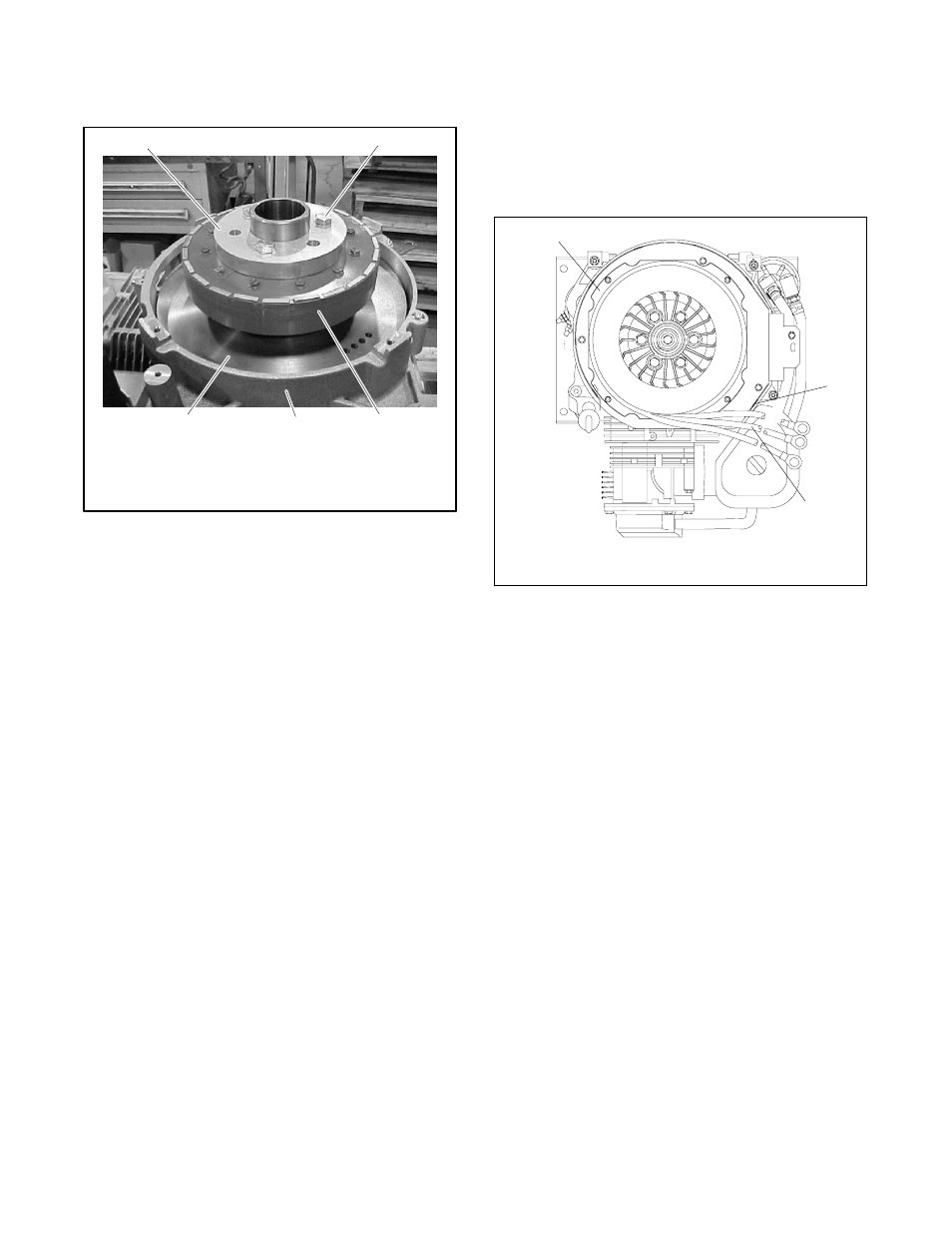

d. Remove the three screws securing the spacer

and rotor to the flywheel. Remove the spacer

and the rotor. See Figure 7-5.

TP-6092

1

3

5

2

1. Spacer

2. Rotor/spacer screws (3)

3. Rotor

4. Engine adaptor

5. Flywheel

4

Figure 7-5

Rotor and Spacer (shroud and stator

removed)

5. Remove the flywheel, if necessary.

a. Remove the thrubolt and convex washer at the

center of the flywheel taper. See Figure 7-4.

b. Pull the flywheel off the engine crankshaft.

7.2 Reassembly Procedure

1. Install the flywheel, if it was removed.

a. Clean the engine crankshaft and flywheel taper

with a dry cloth.

b. Slide the flywheel onto the engine crankshaft.

c. Install the M10-1.50 x 45 mm (1.772 in.)

thrubolt and convex washer. Install the washer

with the convex side up, as shown in

Figure 7-4.

d. Use a torque wrench to tighten the thrubolt to

67 Nm (49.4 ft. lb.).

2. Reassemble the alternator. See Figure 7-4.

a. Slide the rotor over the flywheel taper, aligning

the bolt holes in the rotor and the flywheel.

b. Place the spacer on the rotor, aligning the bolt

holes.

c. Use three 63.5 mm (3/8-16 x 2.5 in.) hex head

screws to secure the spacer and rotor to the

flywheel. See Figure 7-5. Do not tighten the

screws.

d. Place the stator in position as shown in

Figure 7-6. Feed the stator leads through the

opening in the alternator scroll.

1

1. Stator

2. Scroll

3. Stator leads

M-337000A-H

3

2

Figure 7-6

Generator Set Top View

e. Use four 44.5 mm (1/4-20 x 1.75 in. ) socket

head cap screws to secure the stator to the

alternator adaptor. Do not tighten the screws.

f. Use a 0.25 mm (0.010 in.) feeler gauge to

check the gap between the rotor and stator at

several places. Adjust the stator position so

that the gap is even all around. Use a torque

wrench

to

tighten

the

rotor

screws

to

38 Nm (28.0 ft. lb.). Tighten the stator screws

to 11 Nm (8.1 ft. lb.) and verify that the gap is

0.25 mm (0.010 in.) all around.

3. Install the fan.

a. Place the fan on the spacer, aligning the bolt

holes with the three unused holes in the spacer,

rotor, and flywheel.

b. Use three 82.5 mm (3/8-16 x 3.25 in.) hex head

screws and washers to secure the fan. Use a

torque wrench to tighten the screws to

25 Nm (18.4 ft. lb.).

4. Connect the stator leads to the voltage rectifier.

Tighten the voltage rectifier terminal screws to

5 Nm (44 in. lb.).